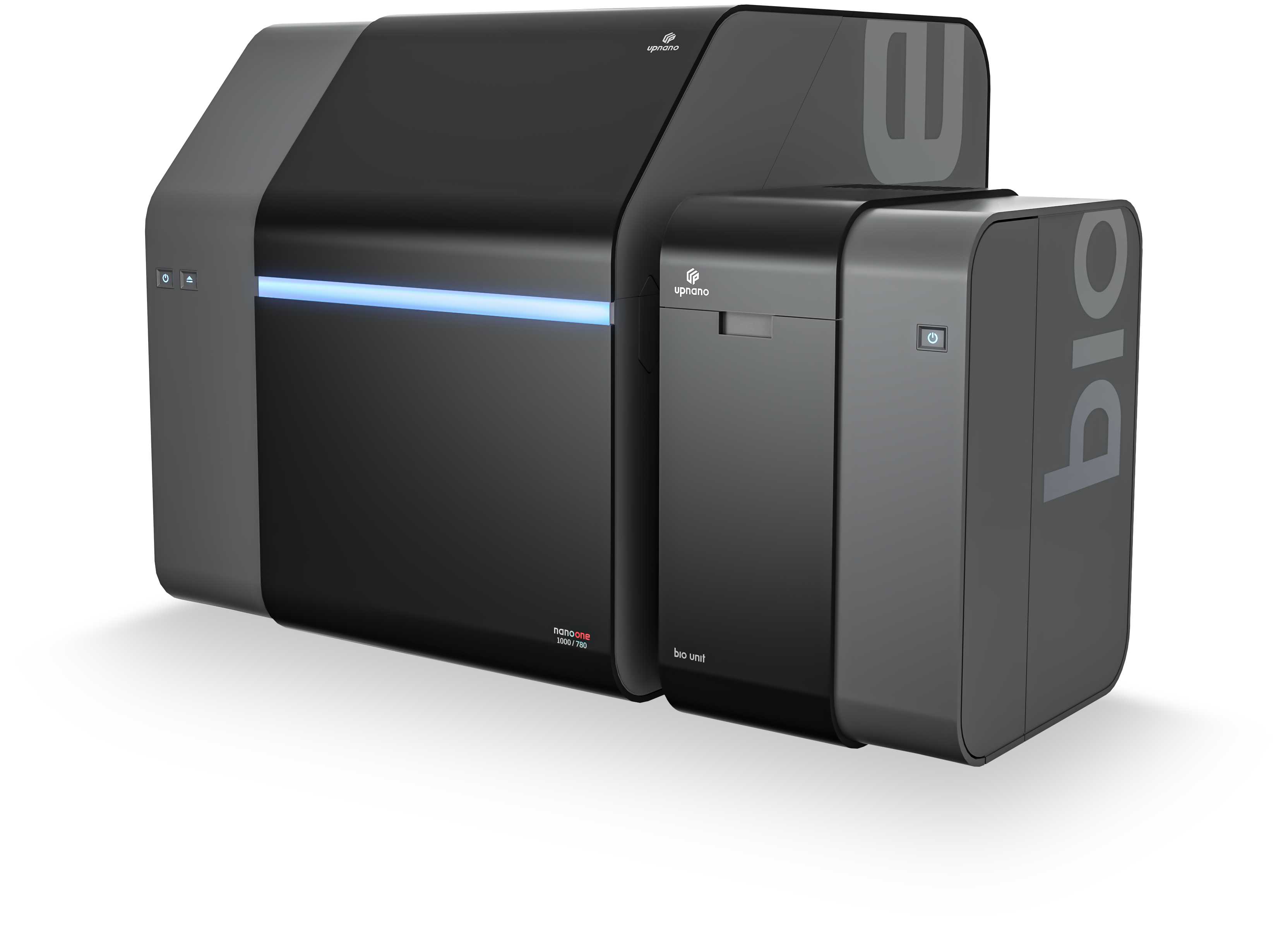

Well plate dock

Well plate dock

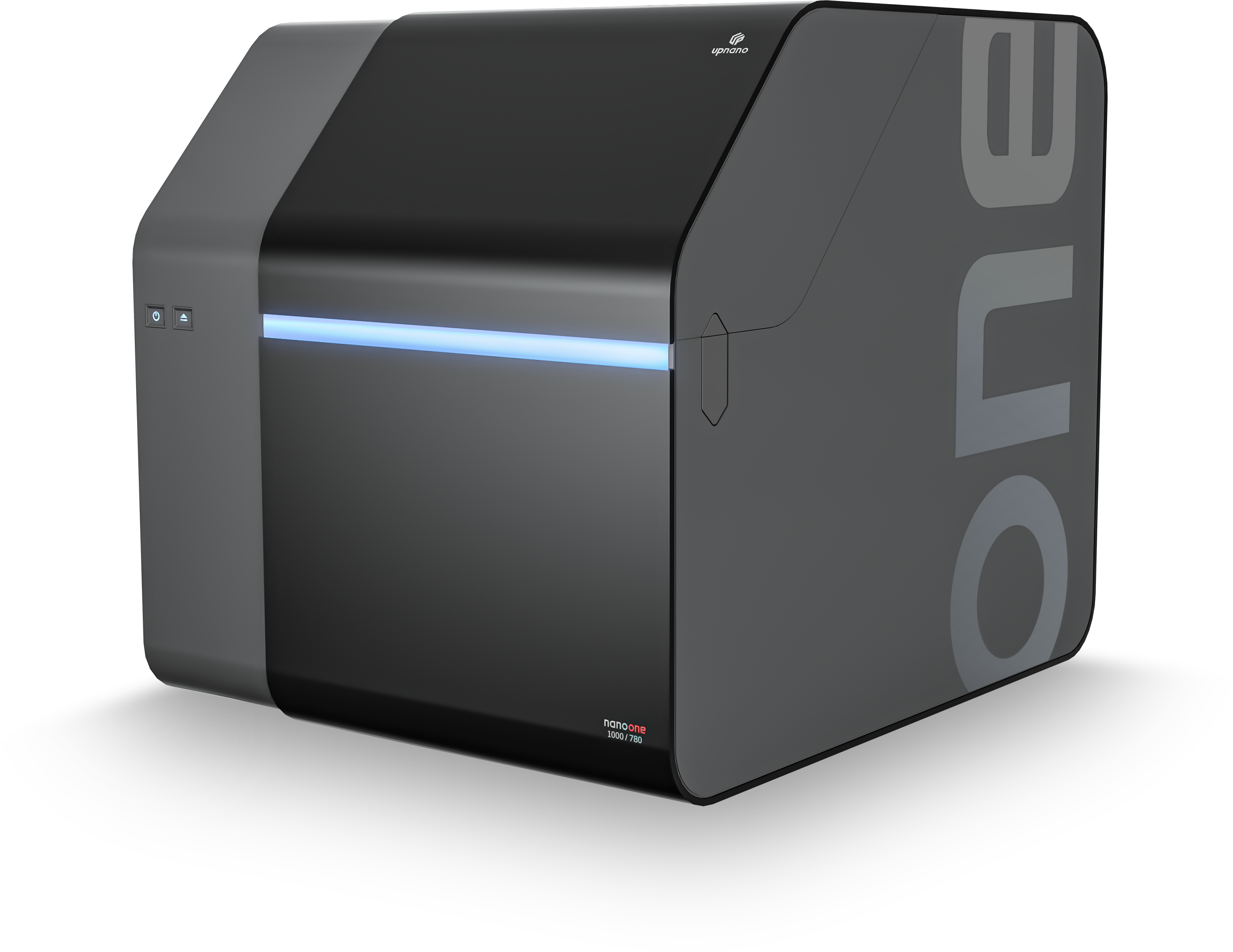

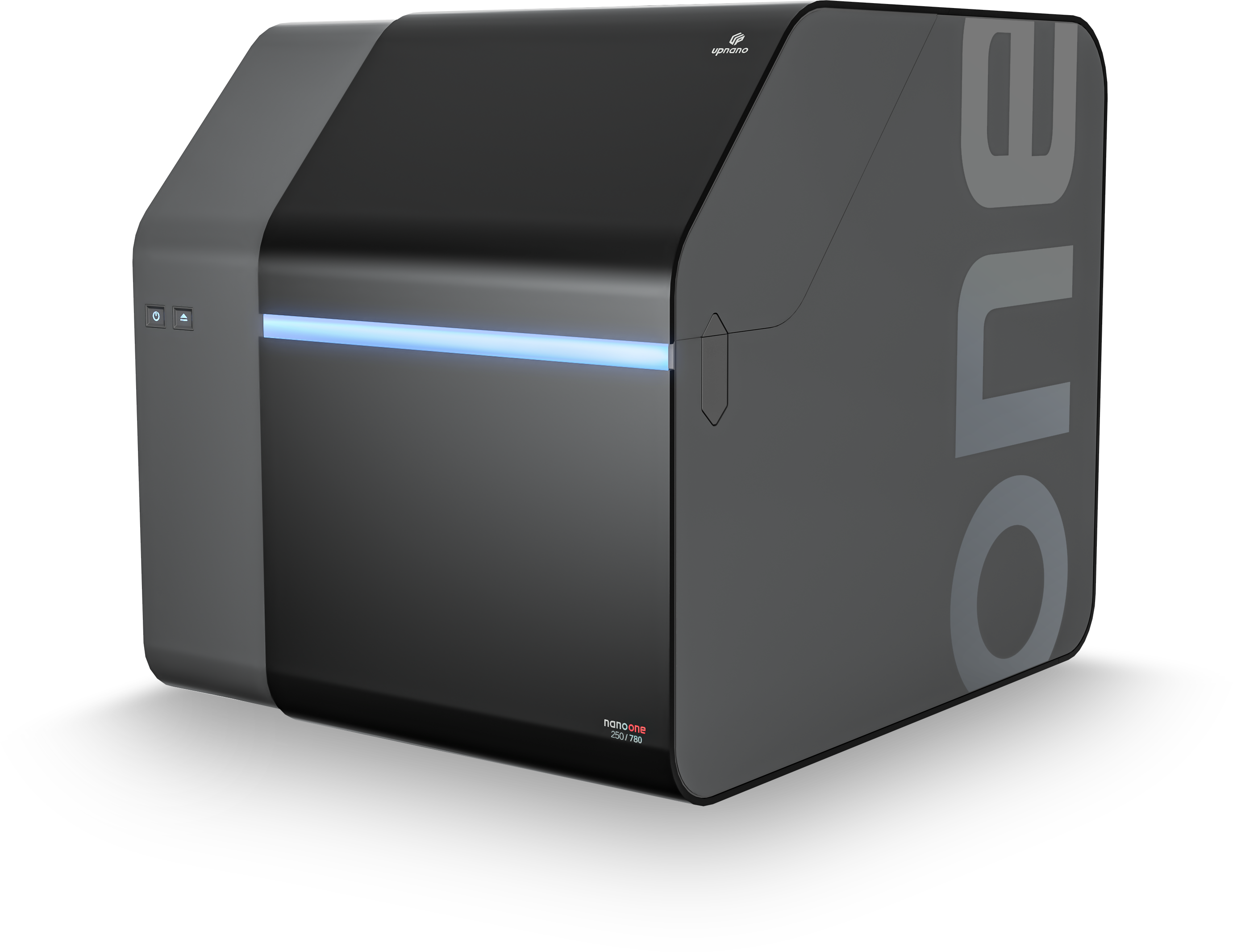

The NanoOne revolutionizes 2-photon polymerization (2PP) printing within multiwell plates, accommodating up to 96 wells. With the support of advanced software solutions, users can effortlessly set up the design and printing process, making automated printing in 96 wells feasible for the first time.

Multitude of substrates supported for bioprinting

The Think3D software seamlessly integrates a wide range of commercial substrates tailored for bioprinting, including renowned µ-slides by ibidi®, versatile 96-well plates, and specialized microfluidic chips. Regular updates continuously expand the list of compatible substrates, and customer-specific substrates can be seamlessly incorporated upon request. The innovative Well Plate Dock feature enables the design and management of multiple well print jobs with ease.

Smart possibilities using integrated autofocus

Benefiting from the utilization of integrated autofocus technology within the Well Plate Dock significantly elevates the placement accuracy of printed structures, ensuring consistent heights across all wells. This feature affords users the flexibility to decide whether to utilize autofocus for focusing on individual wells or opt for a manually defined starting position. By offering this option, users can attain optimal printing results tailored to their unique requirements.

Enhanced functionalities to streamline print job design

Leveraging the exceptional features of Think3D, the Well Plate Dock enhances print job creation and modification by streamlining processes for up to 96 individual prints. This enhancement simplifies operation while preserving users’ freedom to translate their ideas effortlessly into reality. Users can duplicate or link well-specific jobs and parameters, significantly reducing efforts for downstream modifications. Moreover, a concise color-coding scheme ensures an organized overview of the overall layout, enhancing efficiency and user experience.

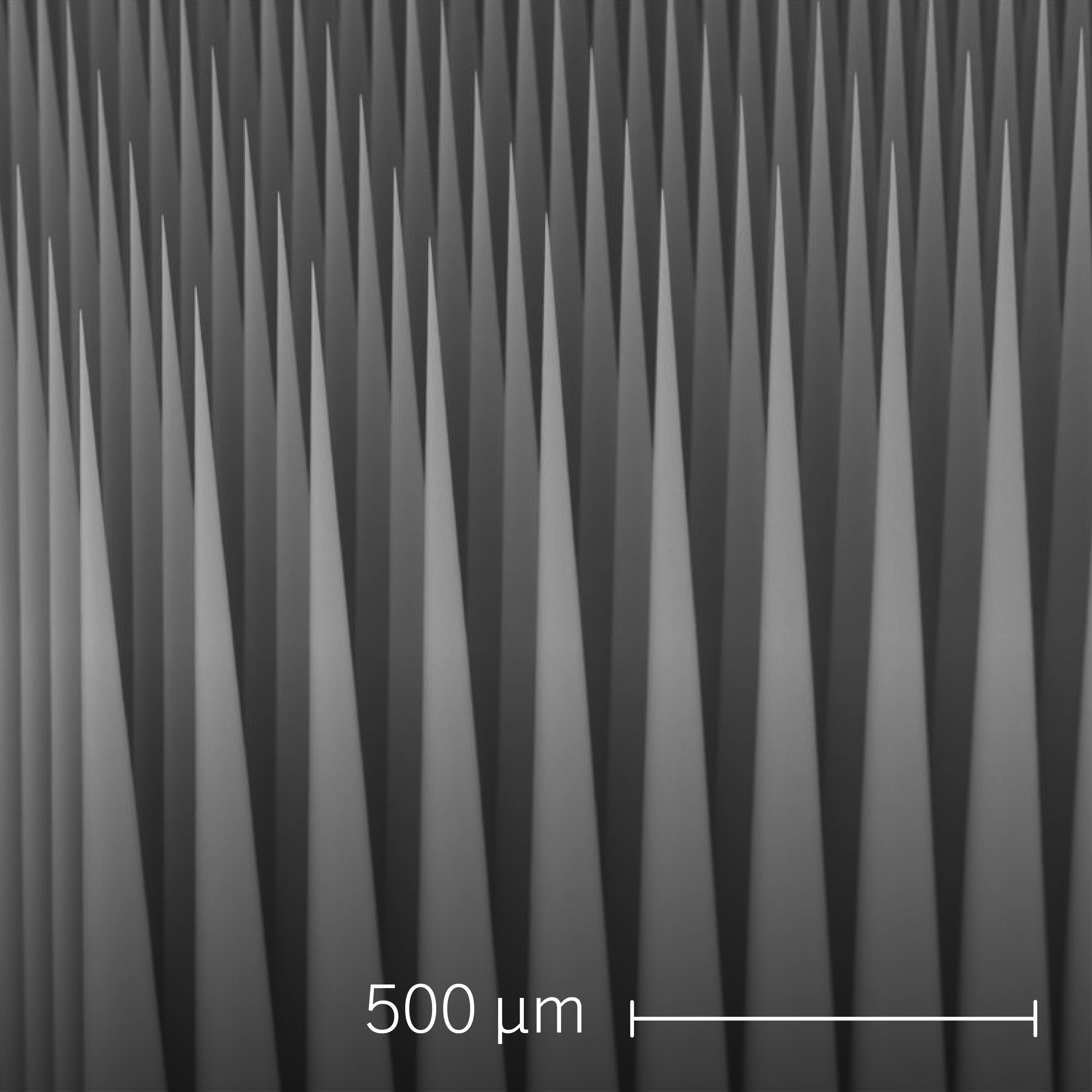

Material property variations via power gradients

The implementation of power gradients in both the xy- and z-directions via the Think3D software provides users with the capability to achieve diverse stiffness within their printed constructs. This functionality holds significant promise in cell culture applications, enabling researchers to mimic the intricate stiffness gradients present in biological tissues. Offering options such as linear, Gaussian, and gyroid gradients, users have extensive flexibility to explore and experiment with various stiffness profiles. This versatility empowers researchers to delve into the impact of varying mechanical properties on cell behavior, tissue development, and other biological processes, thereby providing invaluable insights into tissue engineering and regenerative medicine.