The printing process

A simple process where the highest resolution meets unmatched throughput rates

UpNano’s cutting-edge technology enables the printing of objects ranging in size from the sub-micrometer to the centimeter range, with heights up to 40 mm – all achieved in unprecedented speed.

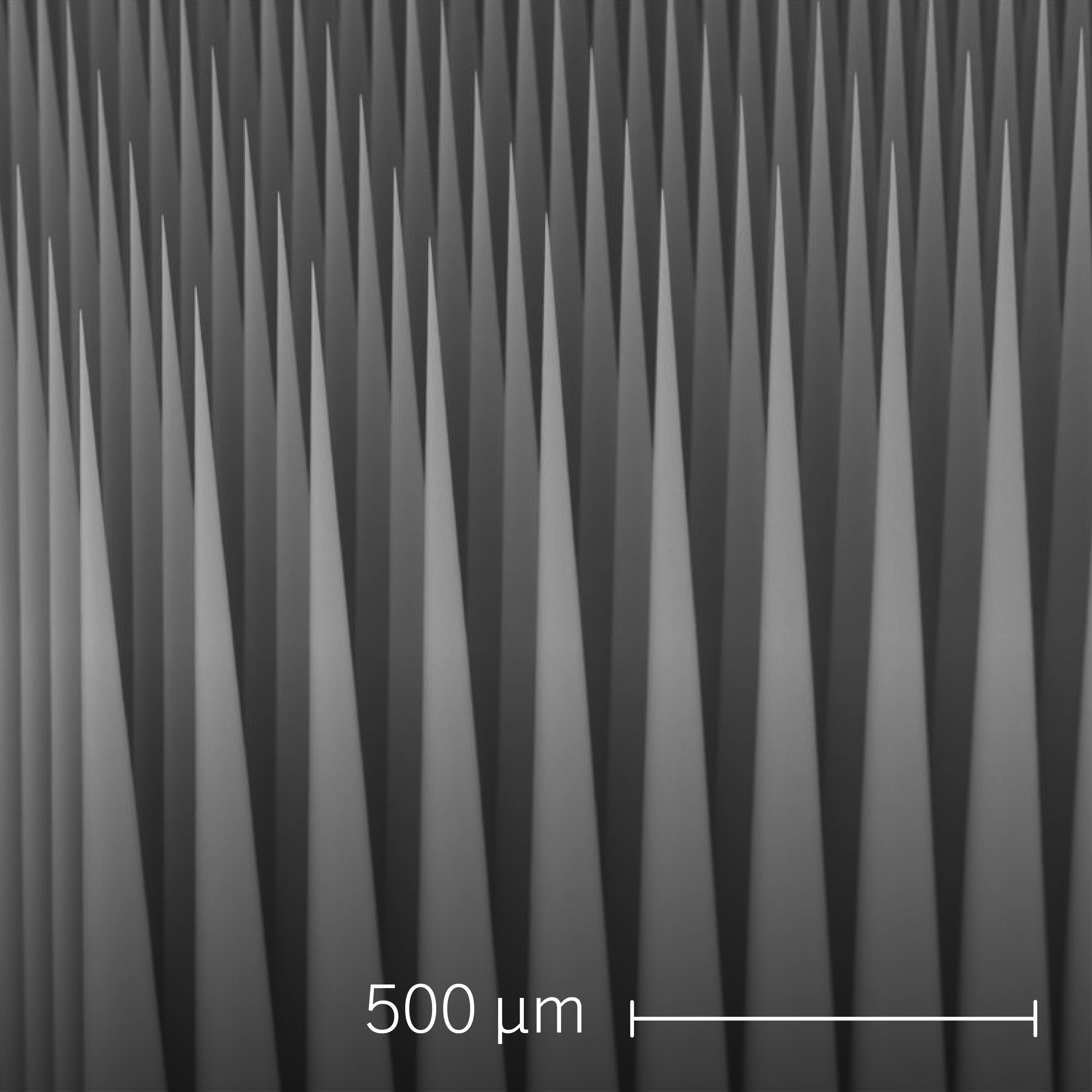

The printing process utilizes a light-based printing method (and belongs to multiphoton lithography) for producing three-dimensional micro-components from plastic. A pulsed femtosecond laser serves as the light source, with the emitted laser beam focused into the viscous resin using high numerical aperture microscope objectives. By scanning the laser beam, the structure is printed according to the imported 3D model, resulting in fully polymerized polymeric components renowned for their exceptionally small and intricate structural details. With few exceptions for special materials, these components can be utilized directly without requiring any post-processing steps.

The choice of microscopy objective determines the size of the so-called voxel, or the focal point of the laser beam, and thus the polymerization volume. Resolution needs and the overall size of the object are critical factors in selecting the objective. Achieving optimal printing time requires striking the right balance between considering the smallest details and the total volume of the component to obtain a satisfying printing result and time.

Higher magnification objectives enable the production finer structural details. With 40x and 60x objectives, lateral details smaller than 200 nm can be realized, while the 5x objective allows for the production of macroscopically large components. The versatility makes UpNano printing systems the fastest and most advanced 2PP-3D printers on the market, covering a manufacturing range of 15 orders of magnitude.

- High degree of design and manufacturing flexibility

- Compatible with standard substrates up to 40 mm edge length

- Vats equipped with cap for convenient resin storage

- Constant focusing power throughout the printing process

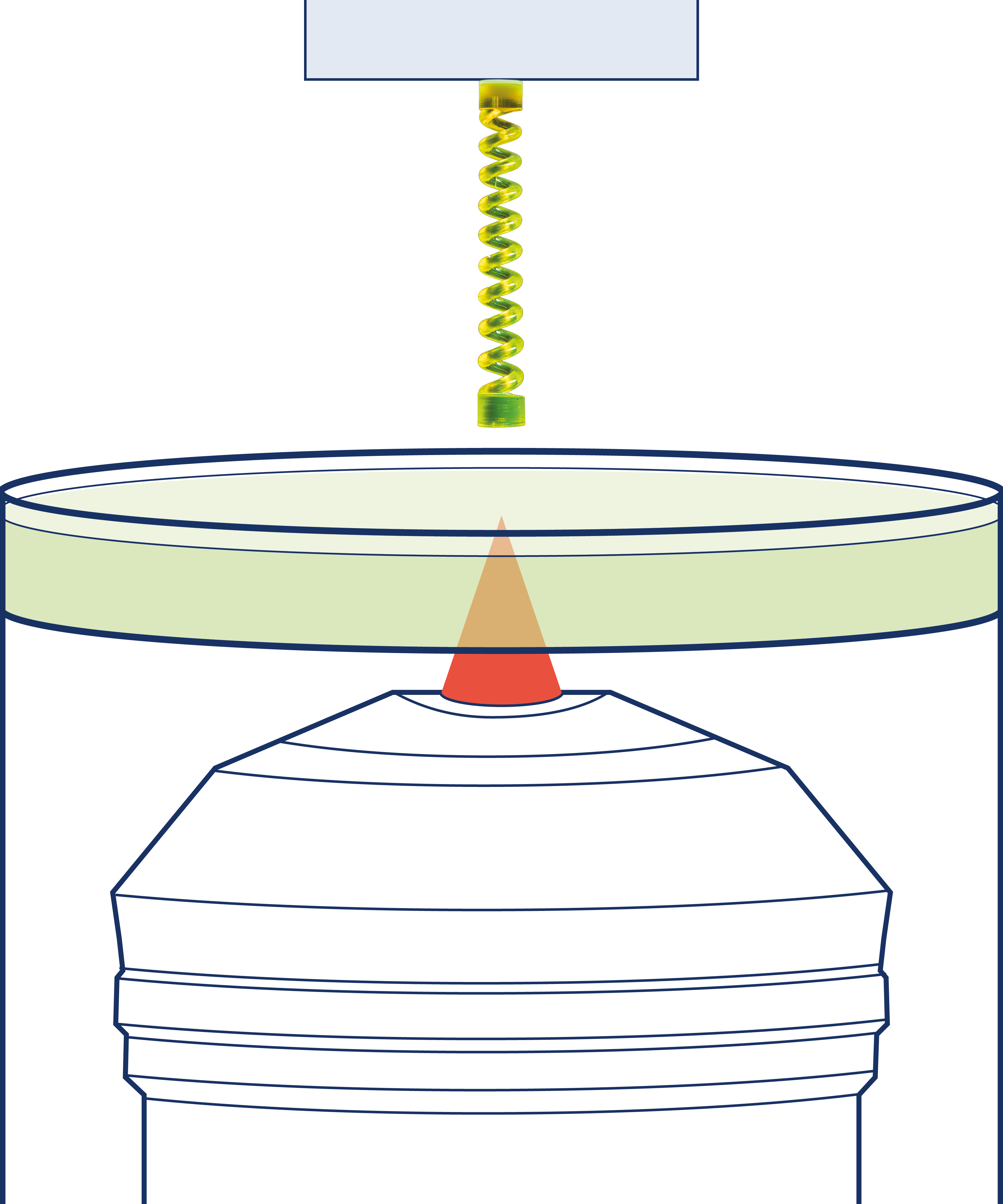

Vat mode

For the production of taller structures, NanoOne offers a unique vat mode that enables the fabrication of large objects with a height of up to 40 mm. In this mode, a vat with a precision glass window is positioned above the objective, preventing resin contact and preserving the focusing power of the objectives. The element is printed layer by layer, with the object being drawn up out of the resin vat while maintaining a constant distance between the current print layer and the objective. This approach ensures consistently high precision throughout the printing process, guaranteeing optimal printing conditions and precise results. It is the preferred printing mode for producing high-quality, large micro-components.

- High degree of design and manufacturing flexibility

- Compatible with standard substrates up to 40 mm edge length

- Vats equipped with cap for convenient resin storage

- Constant focusing power throughout the printing process

- Compatible with most printing resins from the portfolio

- For structuring directly within glass-bottom substrates

- Enables sterile production of micro-components

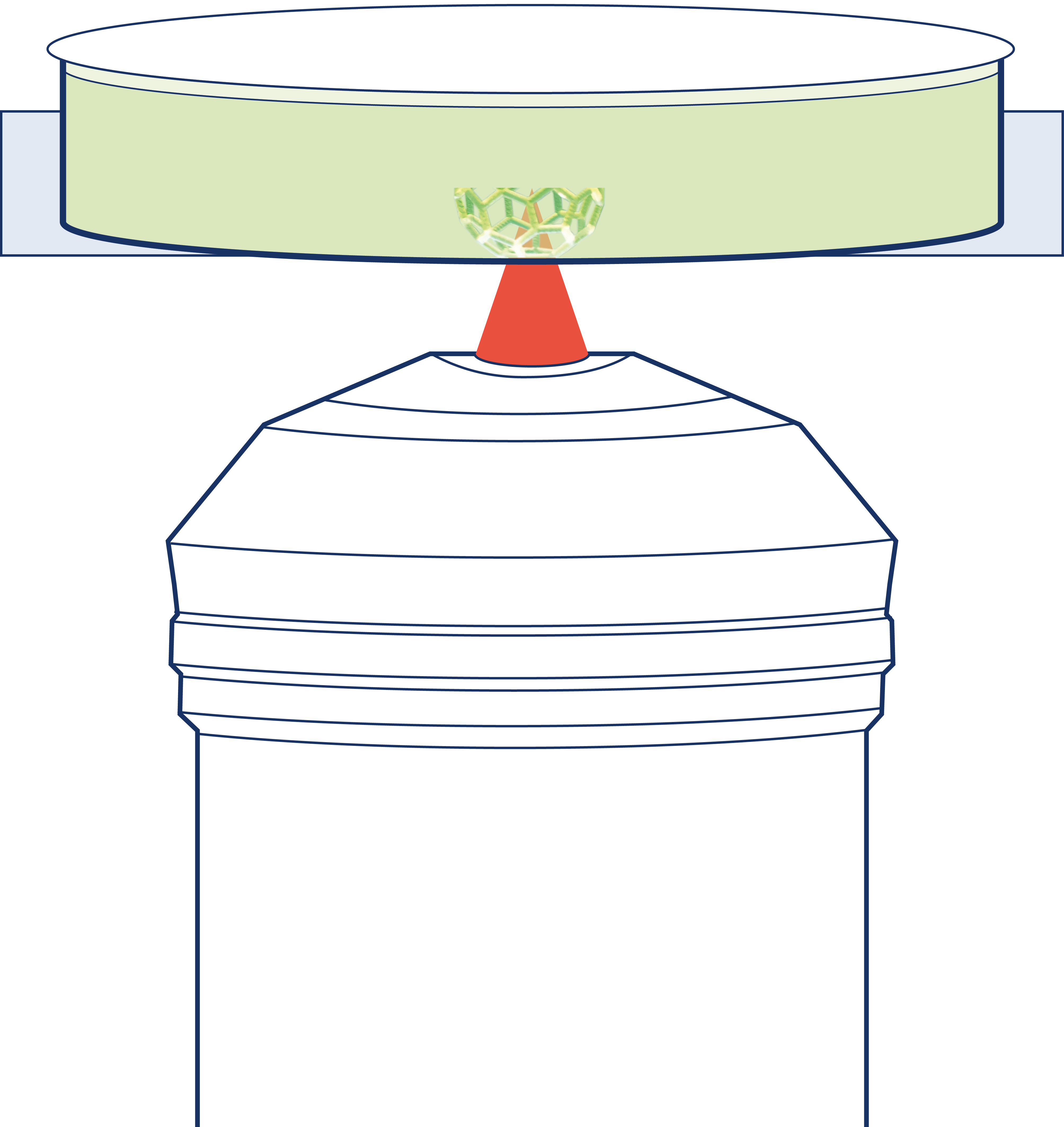

Bottom-up mode

The bottom-up mode provides an effective solution for producing flat structural elements and enables the direct manufacturing of high-resolution structures within a substrate. In this mode, the laser beam is focused through the high-precision glass bottom of the substrate, allowing the structure to be built from the bottom to the highest point of the geometry. Throughout the printing process, the distance between the objective and the build platform gradually decreases. Potential substrates suitable for this printing mode include well plates, petri dishes and microfluidic chips.

- Compatible with most printing resins from the portfolio

- For structuring directly within glass-bottom substrates

- Enables sterile production of micro-components

- For the production of complex, freestanding structures

- Printing of structures within a microfluidic channel

- Suitable for sterile manufacturing of structures and bioprinting

- Micro-component manufacturing directly on wafers

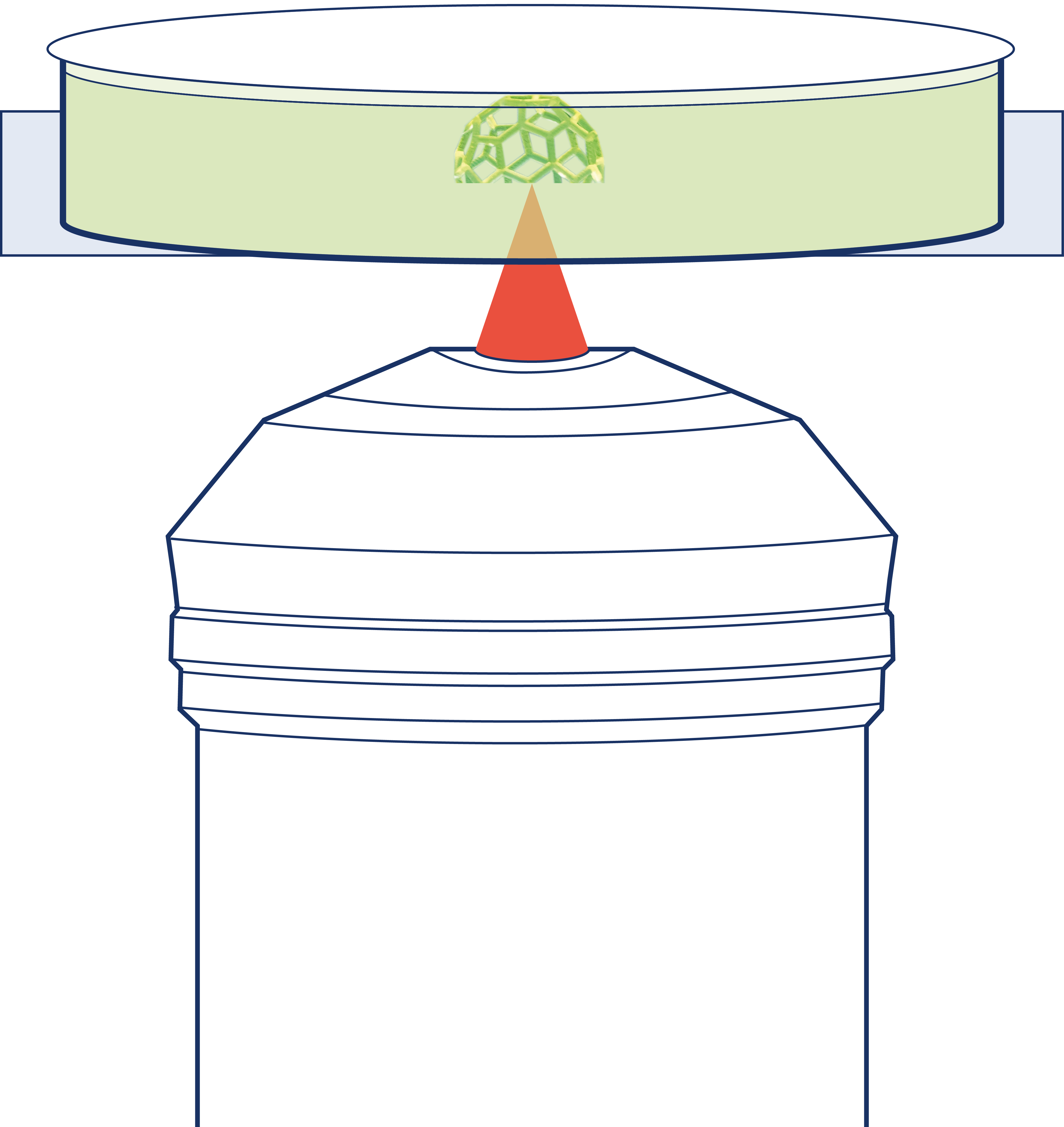

Top-down mode

Similar to the bottom-up approach, resin is applied to or within a chosen substrate. However, the difference lies in the initiation point of printing, which starts at the top of the geometry instead of the bottom. This method prevents objects from being printed through already polymerized resin, ensuring no loss of resolution throughout the printing process as the distance between the objective and the build platform gradually increases. While this print mode presents several advantages, it is limited to certain resins with higher viscosity or when using pre-coated substrates.

- For the production of complex, freestanding structures

- Printing of structures within a microfluidic channel

- Suitable for sterile manufacturing of structures and bioprinting

- Micro-component manufacturing directly on wafers