2-photon resins

Special applications

2PP-3D printing opens up new possibilities in the manufacturing of high-resolution micro-components, meeting the increasing demands for precision, complexity, intricacy, and functionality in various industries. However, alongside design possibilities and manufacturing freedoms, material properties play a crucial role. Our portfolio of resins for special applications excels in this area, offering innovative properties that open up new possibilities.

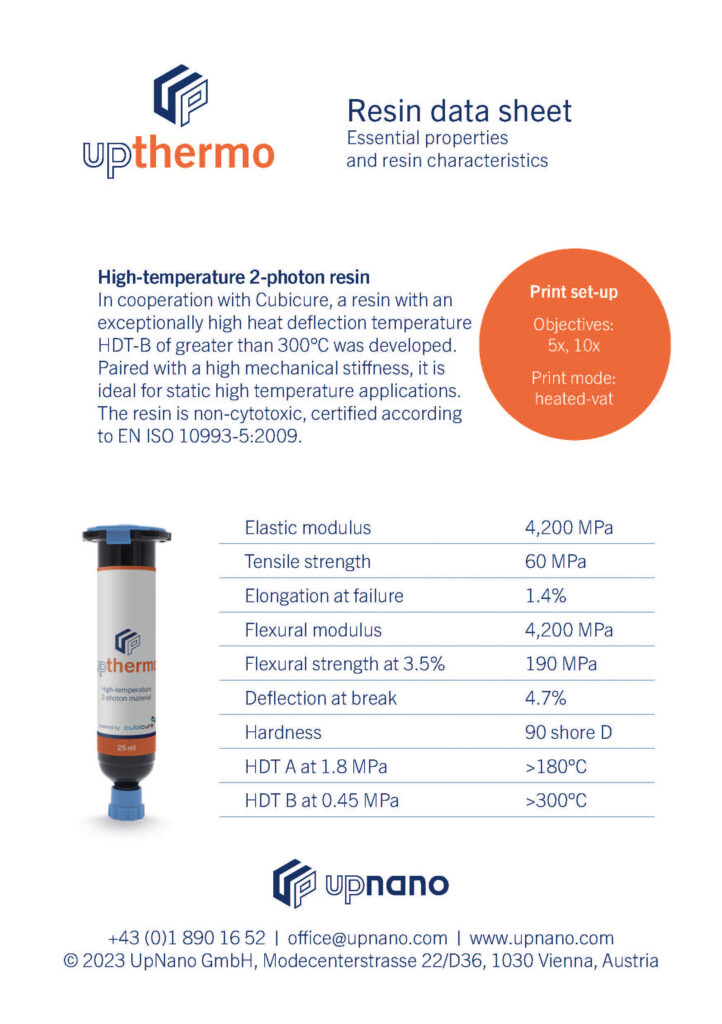

Developed in cooperation with Cubicure, this resin boasts an exceptionally high heat deflection temperature (HDT-B) of greater than 300 °C. Paired with high mechanical stiffness, it is ideal for static high-temperature applications. The post-cured material is non-cytotoxic and certified according to EN ISO 10993-5:2009.

UpThermo – High-temperature 2-photon resin

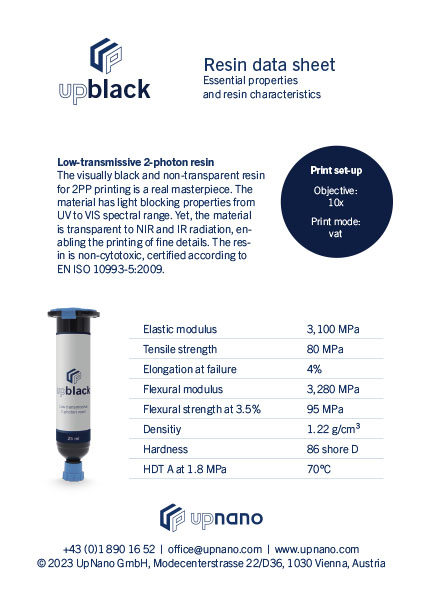

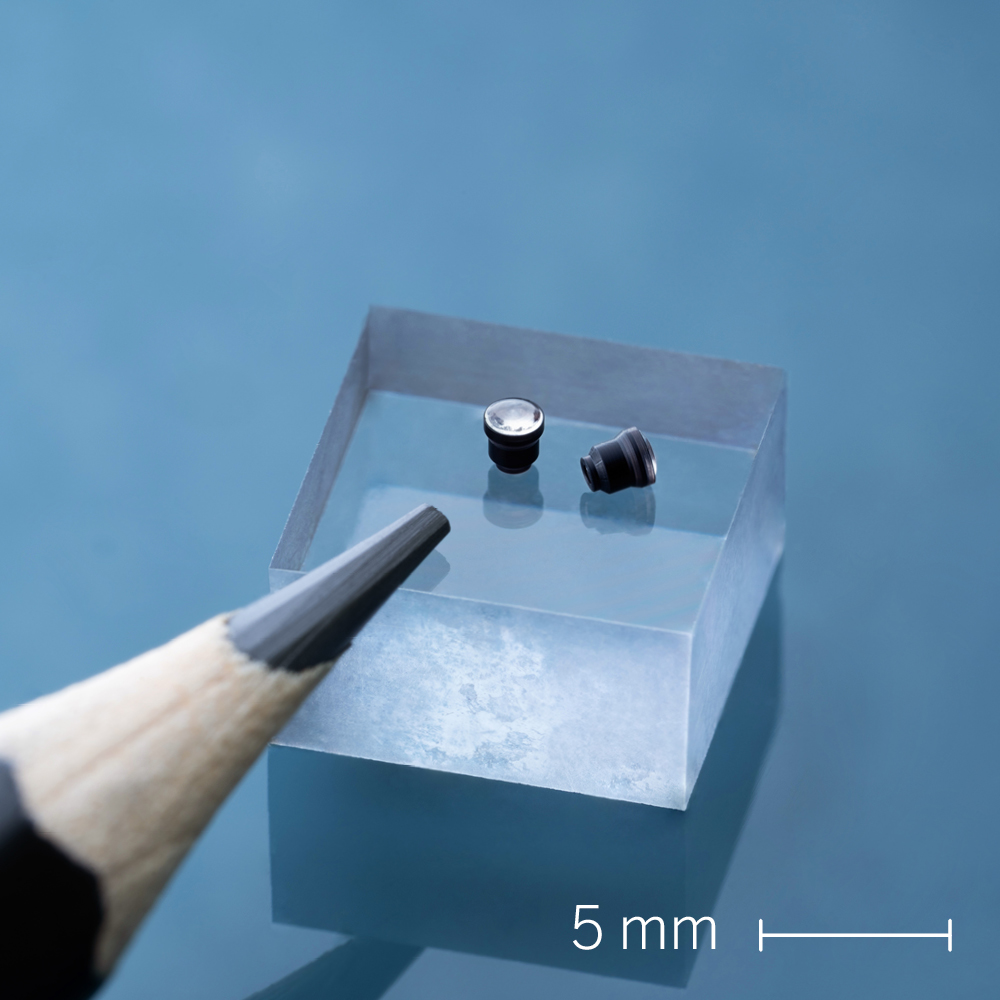

The visually black and non-transparent resin is a masterpiece for 2PP printing. It has light blocking properties in the UV and VIS spectral range, while remaining transparent to NIR and IR radiation, enabling the printing of fine details. The resin is non-cytotoxic and certified according to EN ISO 10993-5:2009.

UpBlack – Low transmissive 2-photon resin

UpQuartz – 2-photon silica slurry

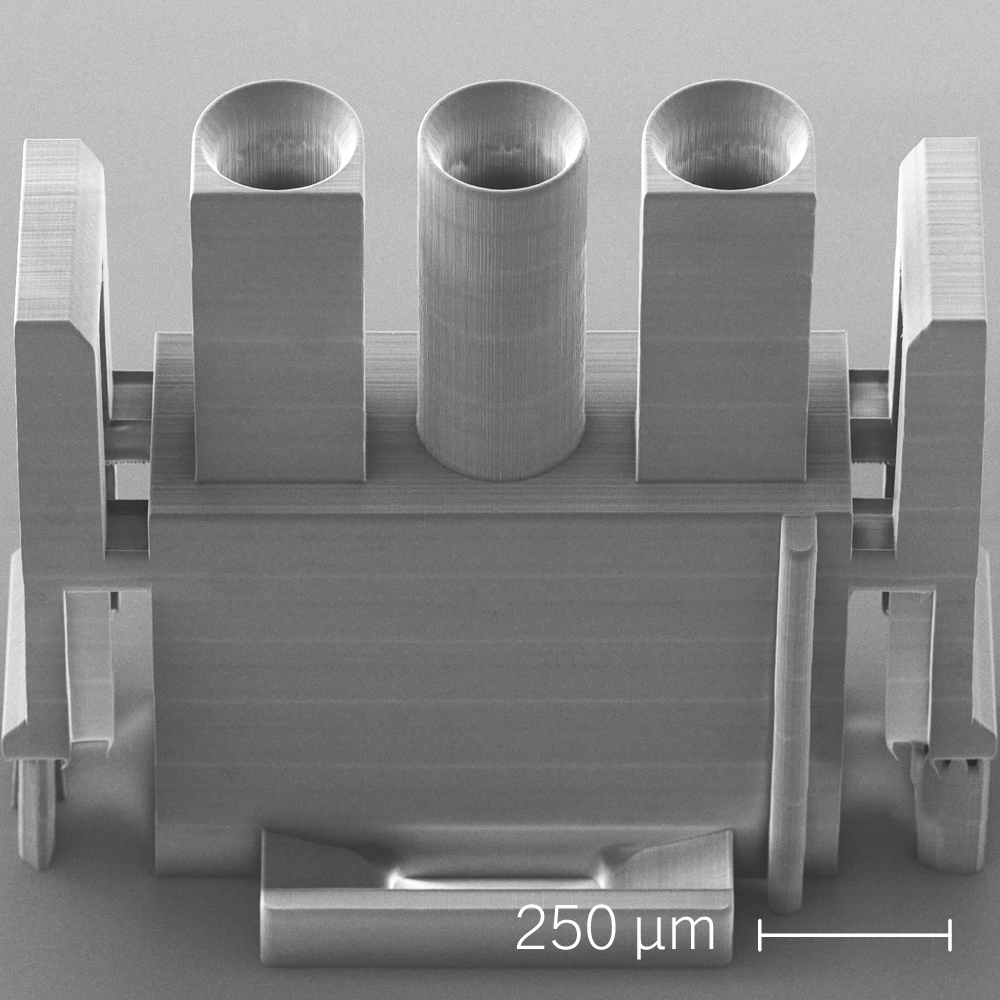

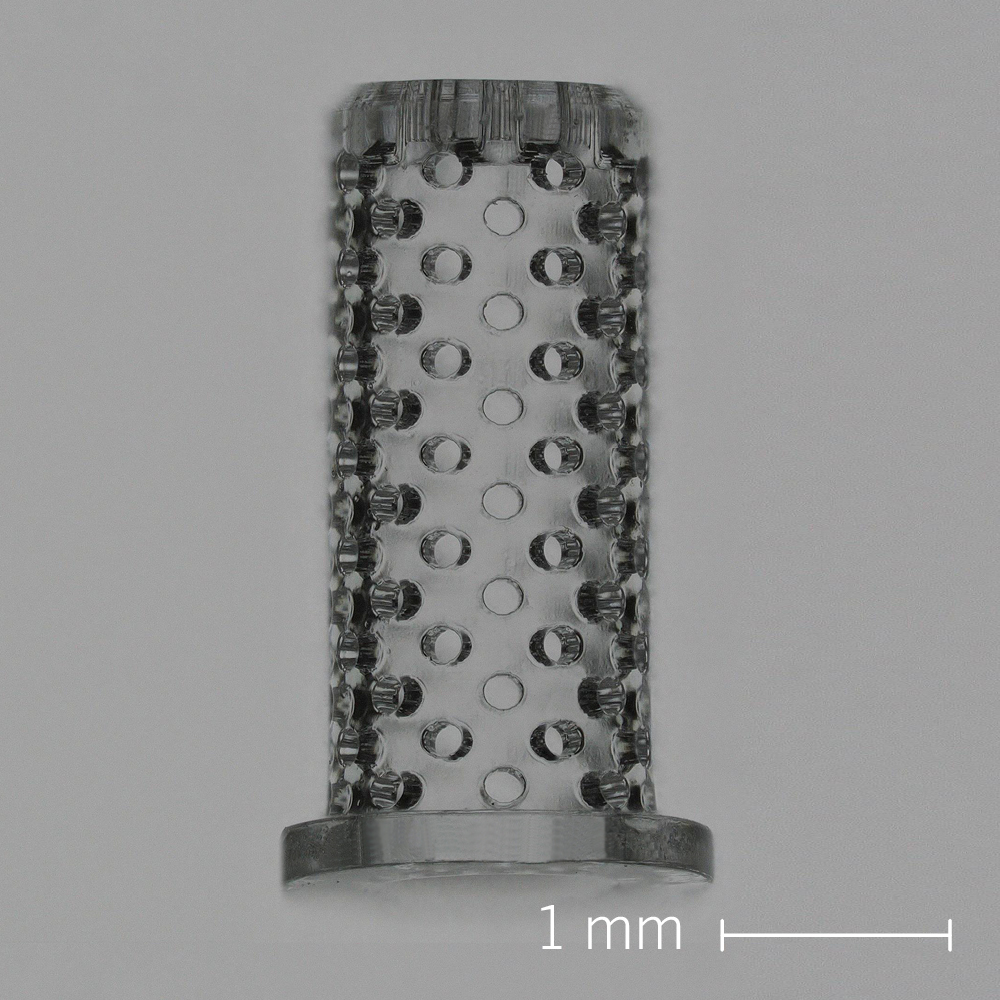

In cooperation with Glassomer, UpNano has developed a nanocomposite slurry for manufacturing fused silica (SiO2) parts using 2-photon polymerization. Printed green parts are converted into fused silica through thermal debinding and sintering. After high-temperature treatment, the 2PP-processed parts exhibit the characteristic properties of fused silica glass.

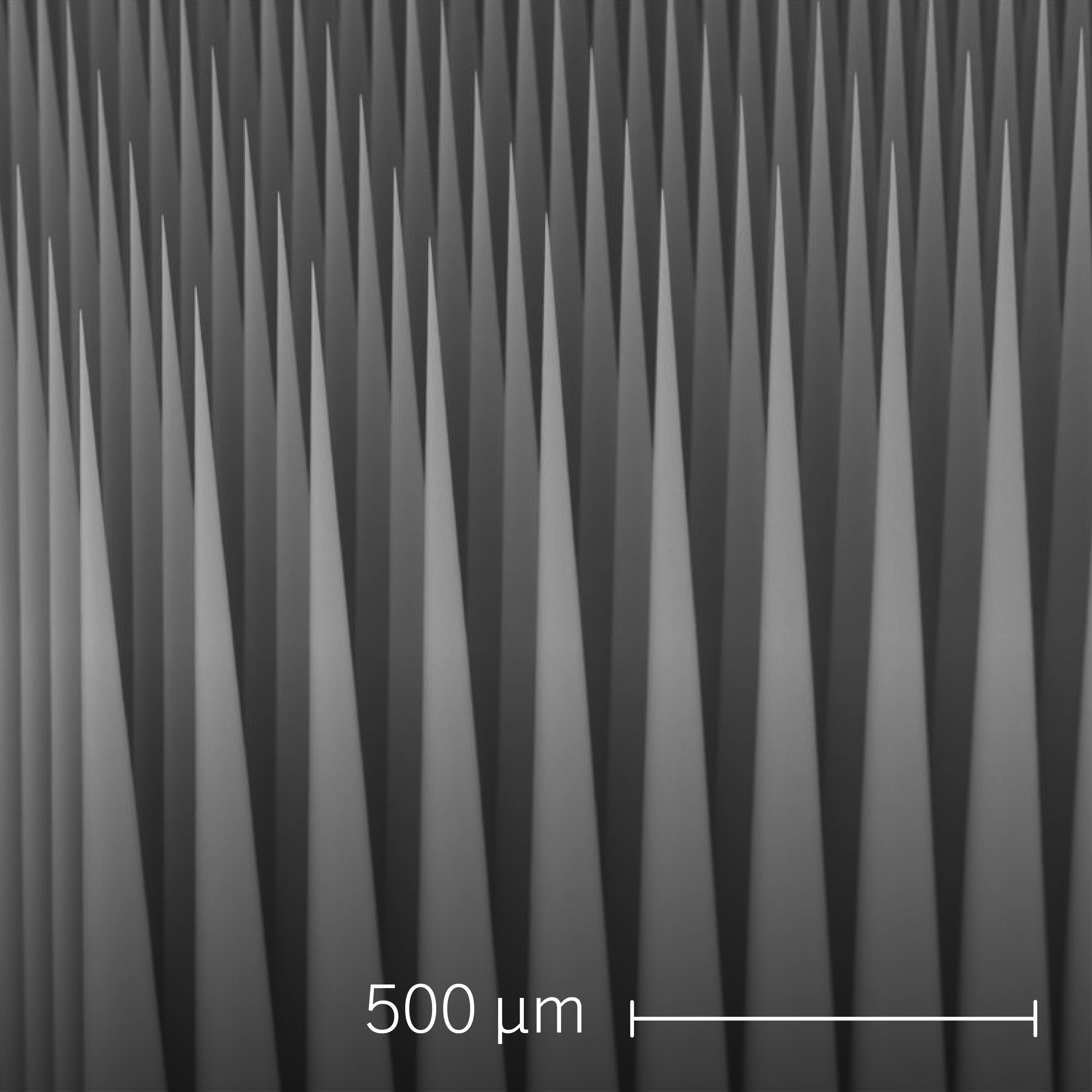

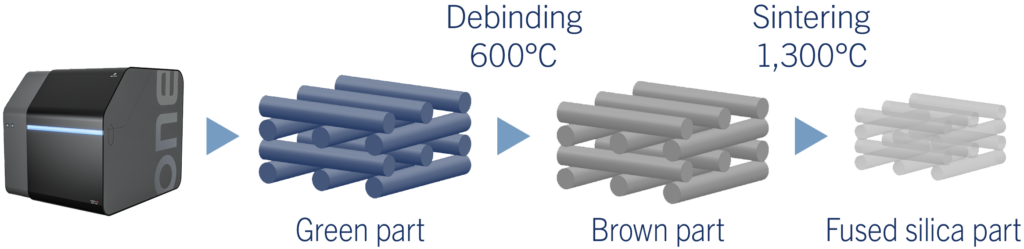

Process of 2PP printing using the UpQuartz silica slurry

This specifically tailored 2PP material enables the production of SiO2 parts with bulk volumes in the mm and features in the μm range. Leveraging the remarkable characteristics of fused silica, including exceptional thermal and chemical resistance, superb mechanical properties, high optical transmission, and inertness, UpQuartz opens the door for applications in which polymers cannot be applied.

The material consists of dispersed SiO2 nanoparticles in a polymerizable binder matrix. First, UpQuartz is 2PP printed to obtain the polymeric green part. Next, the green part is thermally debound at 600 °C to remove the polymer matrix and subsequently sintered to fully dense fused silica at 1,300 °C. During this process, the part undergoes isotropic shrinkage (28%) due to fusing of the SiO2 particles.

Downloads

Please click image to download the document.