Software

One printer, one software

The interplay of hardware, printing resin, and software is an essential cornerstone for a reproducible and high-quality process. Think3D enables easy project creation with a single software interface. Developed by users for users, intuitive operation and remote accessibility were always prioritized during development.

The user interface Think3D is much more than just slicing software, it was programmed from the ground up and designed to meet the requirements of 2PP. In addition to real-time processing of the 3D object into printing instructions, the software offers a whole range of innovative features and widgets to maximize the 3D printing experience.

Adaptive resolution

during printing

Integrated autofocus

and tilt correction

Subjob feature for

advanced printing

Real-time data

processing and slicing

Josef Thalhammer, Team Lead Software Development

“For us, functionality and intuitiveness are top priorities. Think3D has been custom-built to meet the specific needs of 2PP, spanning from the proprietary slicer to the user-friendly interface.”

Print profiles and recipes

for reproducible

results

One-click 3D

model import

interface

Seamless G-Code

file support

3D preview of

print job and

parameters

.thinkage file with

defined print settings

Integrated automated

process supervision

Supports batch

and serial

production

Enhanced logging

and user

management

Software module

upgrades

Print profiles

for reproducible

results

One-click 3D

model import

interface

Seamless G-Code

file support

3D preview of

print job and

parameters

.thinkage file with

defined print settings

Integrated automated

process supervision

Supports batch

and serial

production

Enhanced logging

and user

management

Software module

upgrades

- STL files can be imported from preferred design programs

- Predefined parametrized structures, including aspheric lenses

- Innovative software features such as subjobs, priorities, and arrays

- Enhanced functionality with additional software modules

- Different print modes for perfect results

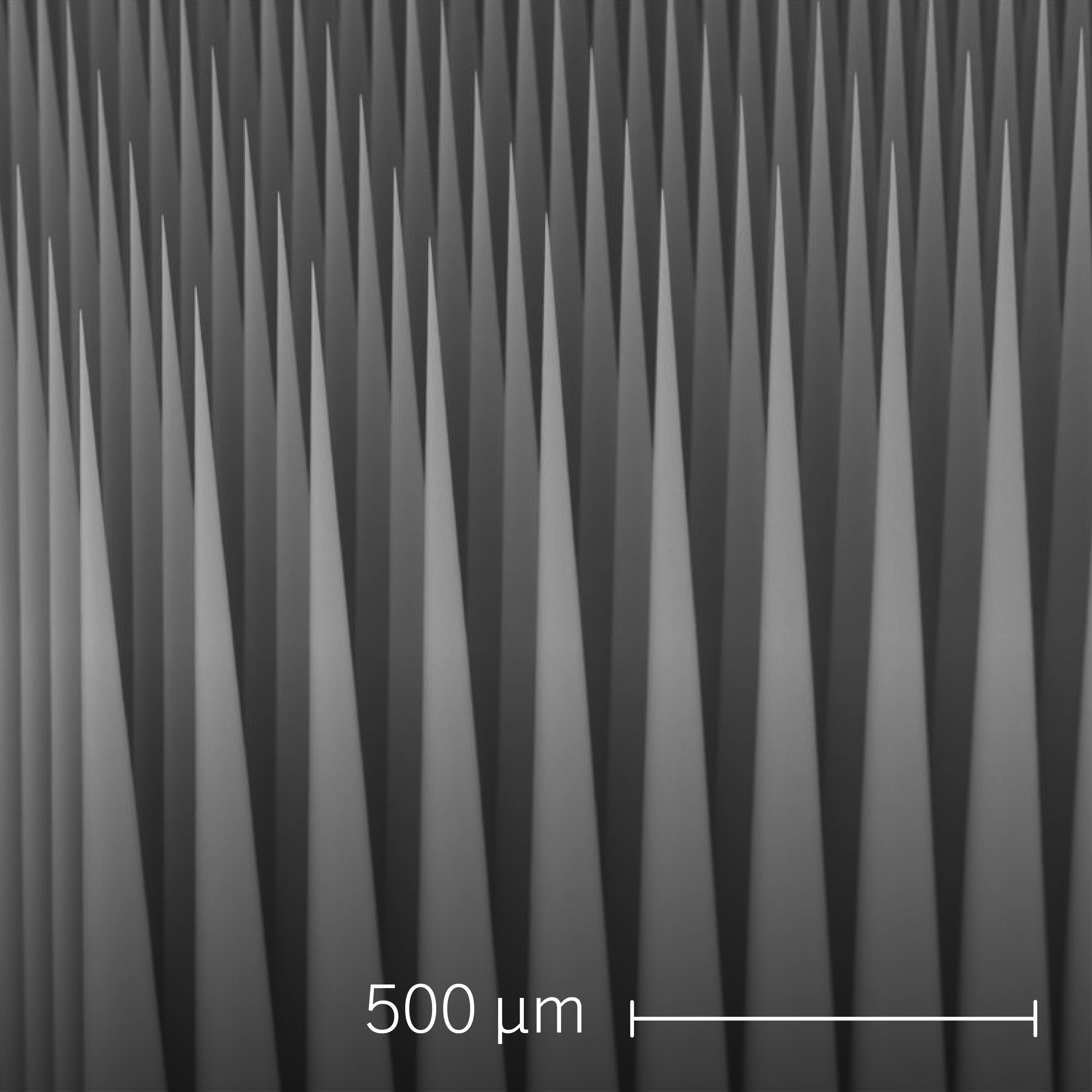

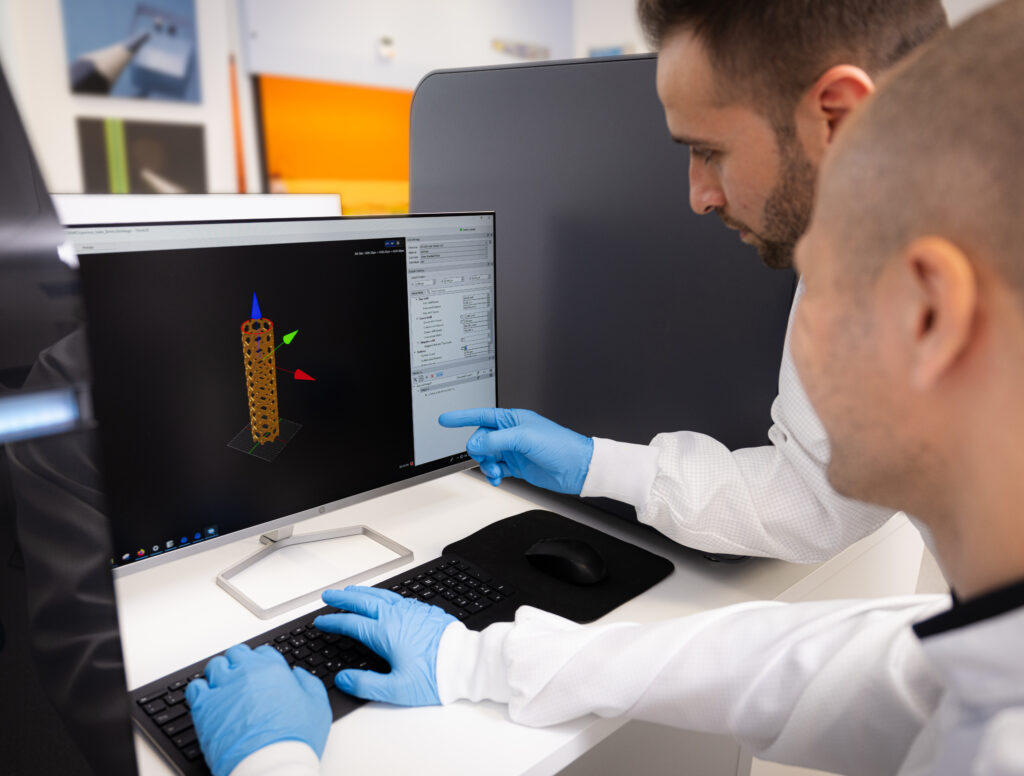

Data preparation

Harnessing cutting-edge technology, unparalleled versatility is provided by the user software Think3D, to elevate designs to the next level. Whether customized CAD objects are imported or predefined parameterized structures are utilized, a streamlined workflow tailored to industrial-grade precision is offered. Exploring a realm of limitless possibilities, features such as customizable arrays of objects, incorporating specialized modules such as lenses or gyroids are seamlessly integrated into print jobs. Additionally, the 3D preview is another benefit and allows the visualization of the designed print.

- STL files can be imported from preferred design programs

- Predefined parametrized structures, including aspheric lenses

- Innovative software features such as subjobs, priorities, and arrays

- Enhanced functionality with additional software modules

- Different print modes for perfect results

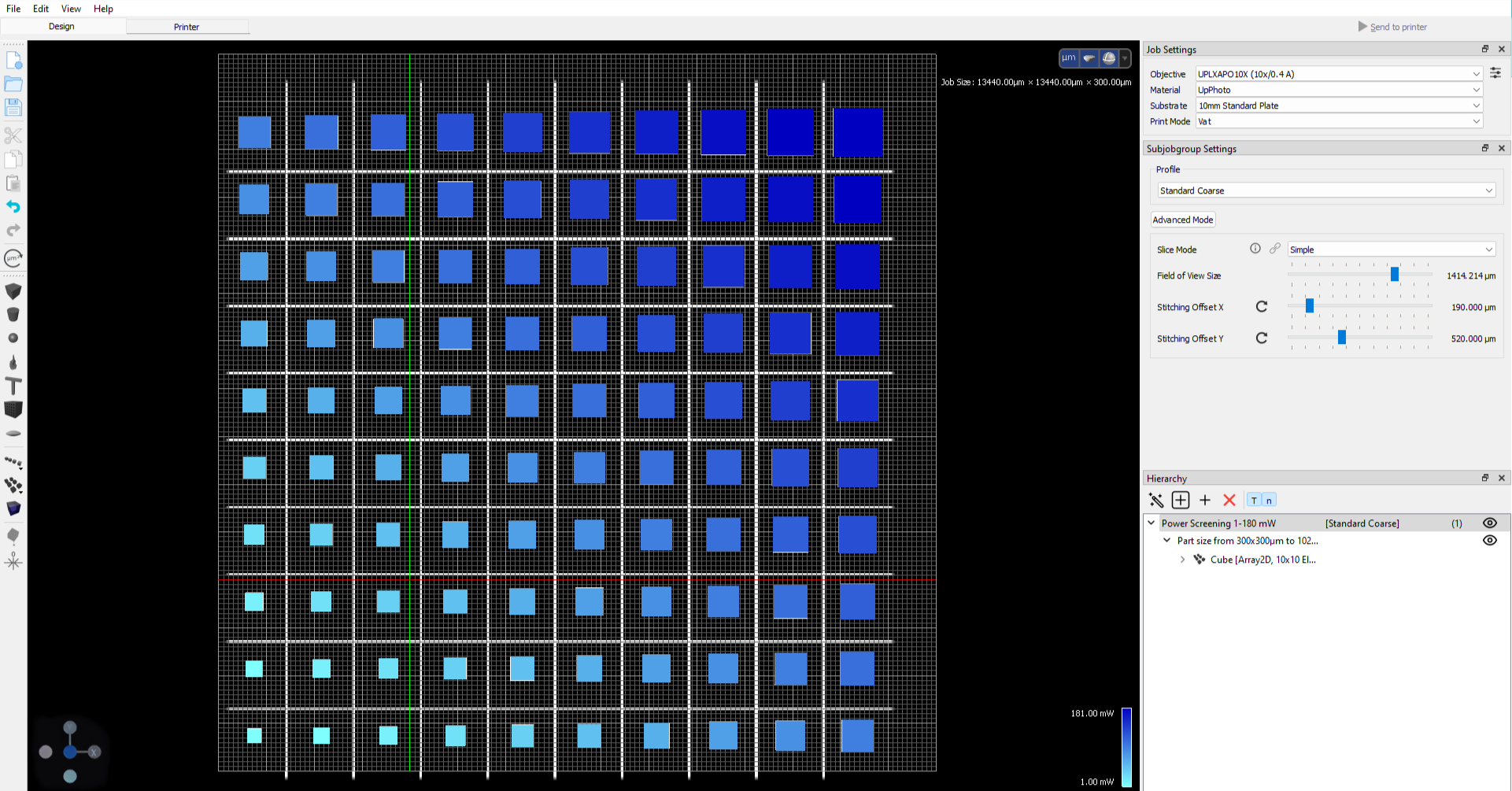

Parameters

The option to select predefined print profiles or create customized data sets is available. These profiles guarantee cost-efficient and high-quality print outcomes, precisely aligned with the selected objective-resin combination. Furthermore, parameters can be tailored for individual objects or power gradients can be implemented within an object. To achieve maximum adaptability, leverage the “custom data” function of the software to fine-tune parameters according to the respective part specifications and requirements.

- Part dimension can be controlled and adjusted to meet exact requirements

- Ensure prints are precisely aligned and positioned with perfection

- Fine-tune laser power and energy distribution settings to optimize results

- Effortlessly manage scan velocity adjustments, stitching and outline mode

- Individually select quality parameters of objects to maximize throughput

- Part dimension can be controlled and adjusted to meet exact requirements

- Ensure prints are precisely aligned and positioned with perfection

- Fine-tune laser power and energy distribution settings to optimize results

- Effortlessly manage scan velocity adjustments, stitching and outline mode

- Individually select quality parameters of objects to maximize throughput

- Advanced process monitoring is ensured by a 20 MPixel sample camera

- Precise alignment is facilitated by a 5 MPixel top view camera along with the sample camera

- An integrated autofocus system for substrate detection and tilt compensation

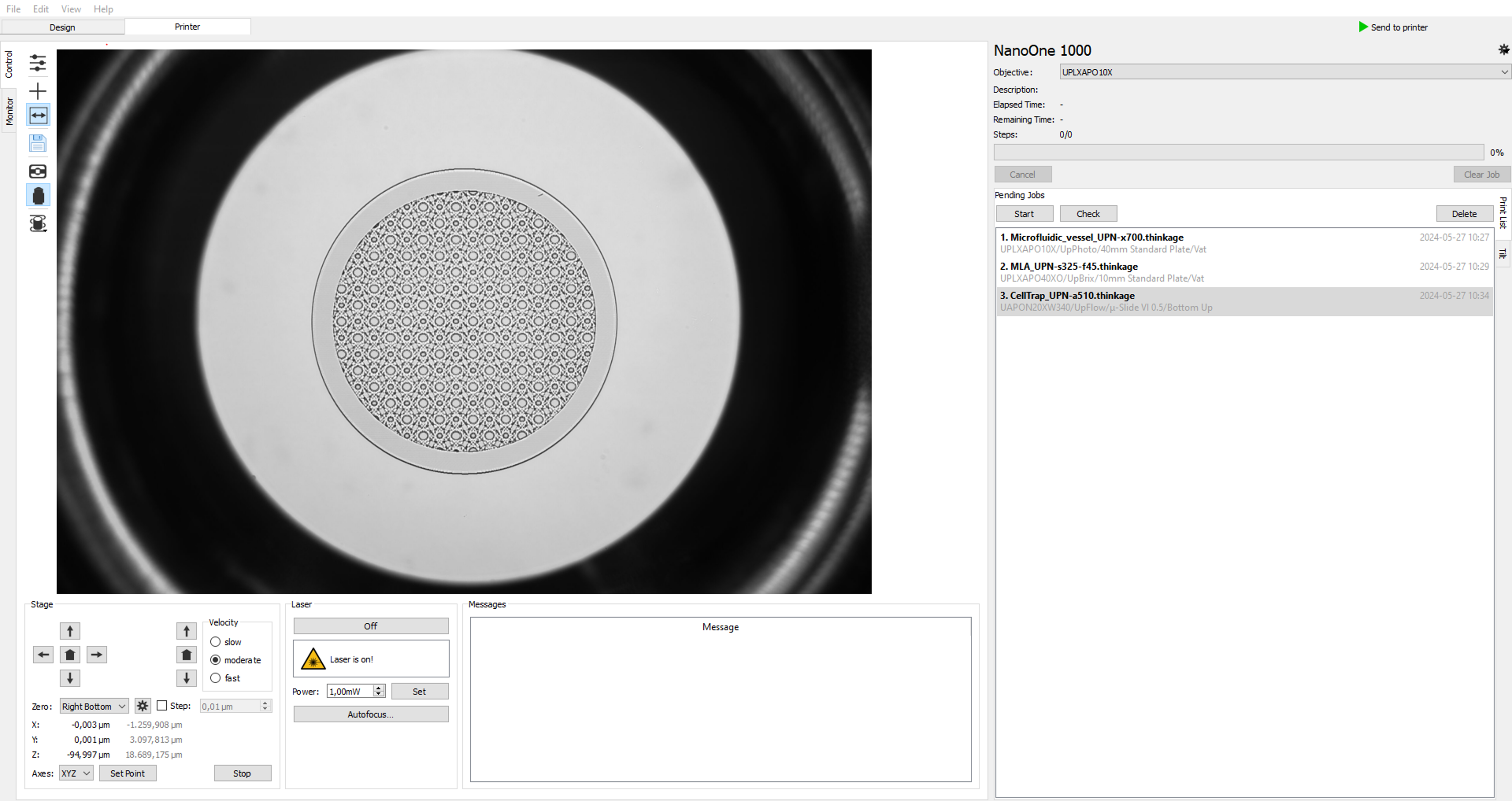

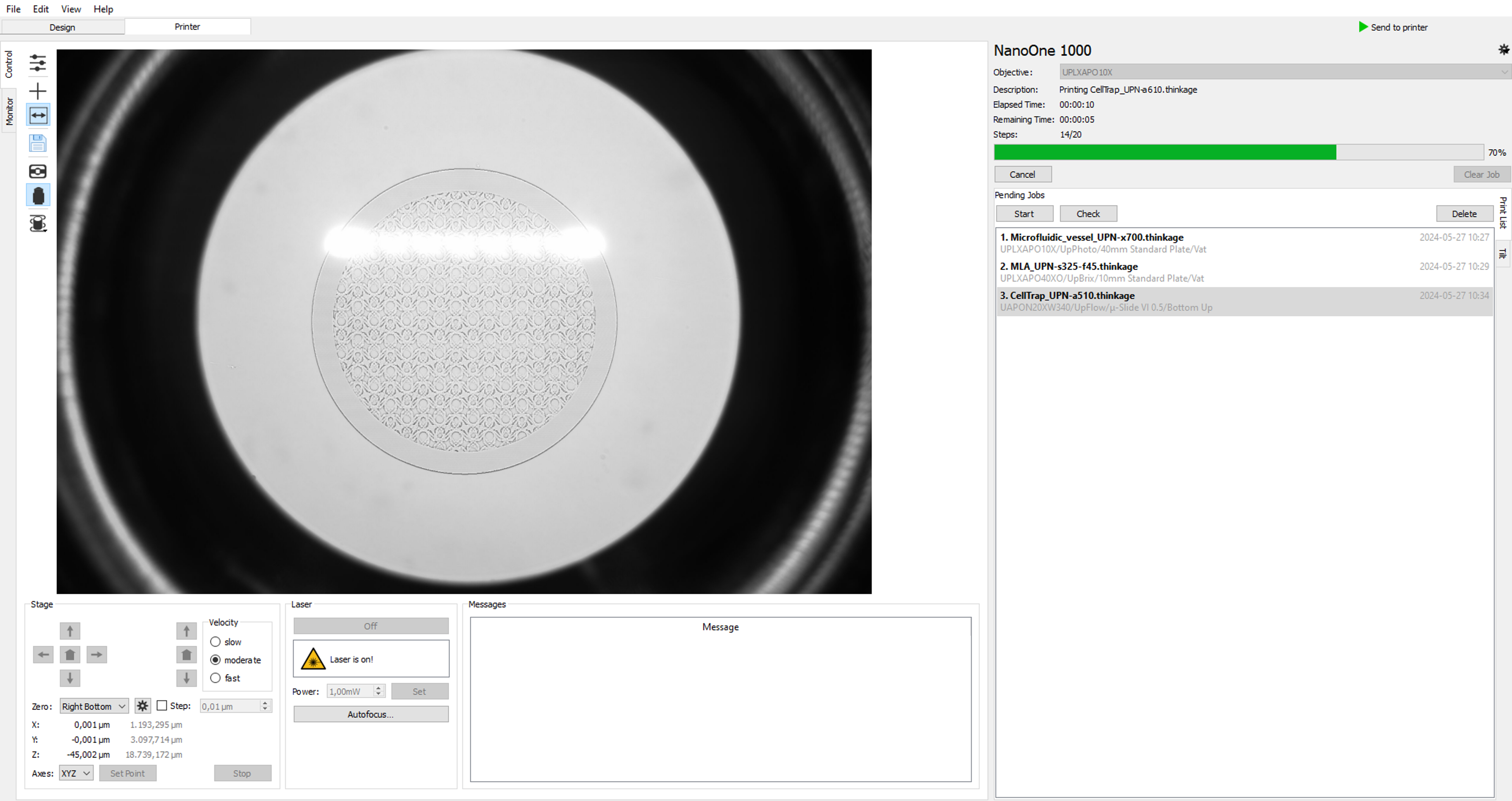

Live view

Experience unparalleled process monitoring with our advanced camera systems. Witness the printing process in real time and leverage the integrated autofocus system for precision. Easily realign prefabricated structures with the assistance of our dual camera set-up. One camera captures the current print layer through the microscope objective, while the second provides an overhead view of the building platform. Gain full control and monitoring of the printing process at any time – even remotely.

- Advanced process monitoring is ensured by a 20 MPixel sample camera

- Precise alignment is facilitated by a 5 MPixel top view camera along with the sample camera

- An integrated autofocus system for substrate detection and tilt compensation

Real-time printing

Our cutting-edge software and slicing algorithm processes all required data in real time, optimizing system manageability by minimizing stored data. The printing process on all UpNano printing platforms can be started instantly, eliminating the need for preprocessing imported files and allowing for very fast prototyping production in just 2 clicks.

- Jobs can be started without preslicing by our advanced software

- Data storage and preprocessing requirements are minimized

- Equipment compatibility is ensured through automated barcode validation

- Jobs can be started without preslicing by our advanced software

- Data storage and preprocessing requirements are minimized

- Equipment compatibility is ensured through automated barcode validation