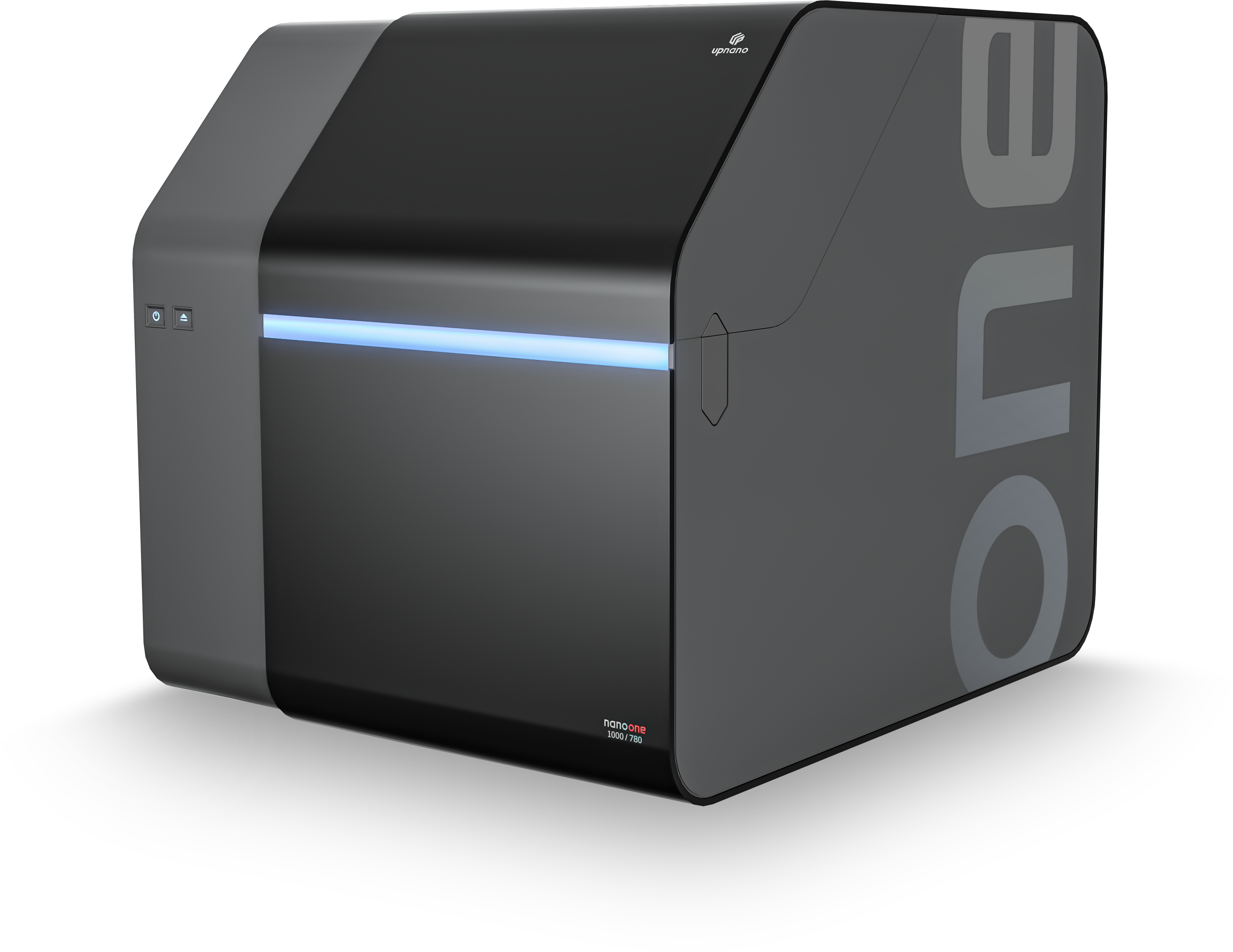

Operating software

Intuitive printing

The Think3D user software from UpNano is designed to guide users from the initial print setup to the final product with intuitive ease. By providing a user-friendly interface and intuitive connectivity options, UpNano ensures that users can effortlessly navigate the printing process and achieve their desired results with minimal effort.

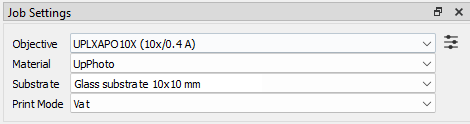

The process starts with configuring the print options to precisely match the requirements of the desired part. Users can choose from various substrate types, objectives, resins, and print modes, to match the requirements of the project. With UpNano’s versatile and customizable printing platforms, the possibilities are almost endless.

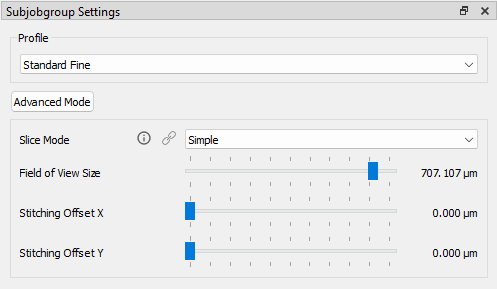

Once the fundamental parameters are established, users can load the structure to be printed into the software. Predefined printing profiles are available for all objectives and resins supported by UpNano, although users also have the flexibility to customize and optimize print parameters.

The print job and its parameters can be defined using the offline version of the Think3D user software, with the option to either start the predefined print job directly or save it for future use.

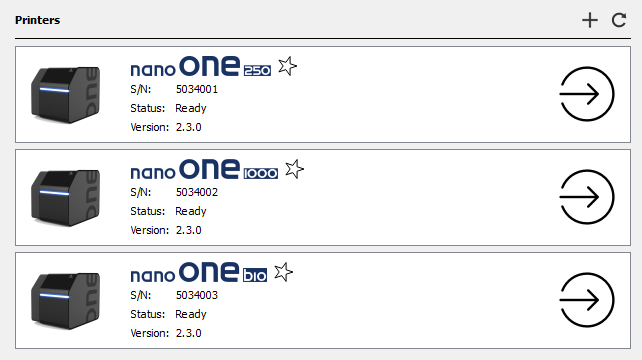

Upon establishing a secure network connection to the printer and logging into the system, users can effortlessly send the print jobs to the UpNano printing system with a single click. This streamlined process ensures convenience and efficiency, allowing users to easily transfer their designs and projects to the printer.

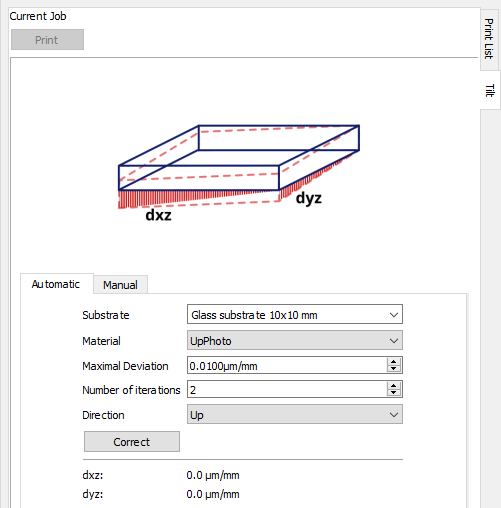

With the state-of-the-art integrated autofocus and tilt correction system, the printer automatically detects the substrate surface and adjusts it to achieve optimal alignment. This innovative technology simplifies the printing process while guaranteeing high precision and accuracy.

The print job is initiated with a simple click to start. Thanks to the integrated camera systems, the printing process can be observed in real time as each layer takes shape. Not only can users monitor the progress, but they can also document the print. The data generated is used to optimize the process, ensuring a repeatable result suitable for industrial use.