NanoPro VT

The engine powering our service

UpNano has taken all the expertise and learnings from the NanoOne, our line of desktop, modular 2-photon polymerization based 3D printers, and developed a machine built for industrial-scale production: the NanoPro VT.

“VT” stands for “Voxel Tuning,” which describes the patented technology we use to make this machine substantially faster in terms of throughput to meet the demands of high-volume production.

The NanoPro VT will set new standards and allow 2PP 3D printing to overcome its stigma of being only a prototyping, small-volume and research-oriented technology. It proves that 2PP 3D printing is in fact the only solution to achieve the balance of fast production and complexity of design needed for mass micropart production.

Technical specs

Optical power engine: 32 Megavoxels/second

Up to 7-watt laser at 515 nm wavelength

Wide use of various substrates

Max print range:

200 x 200 x 50 mm

Automated objective and substrate exchange

HEPA 14 filtered air

Temperature stability

(0.1 °C/32.18 °F)

Vibration insolation

Automated basic post processing (specific post processing steps to be developed per part)

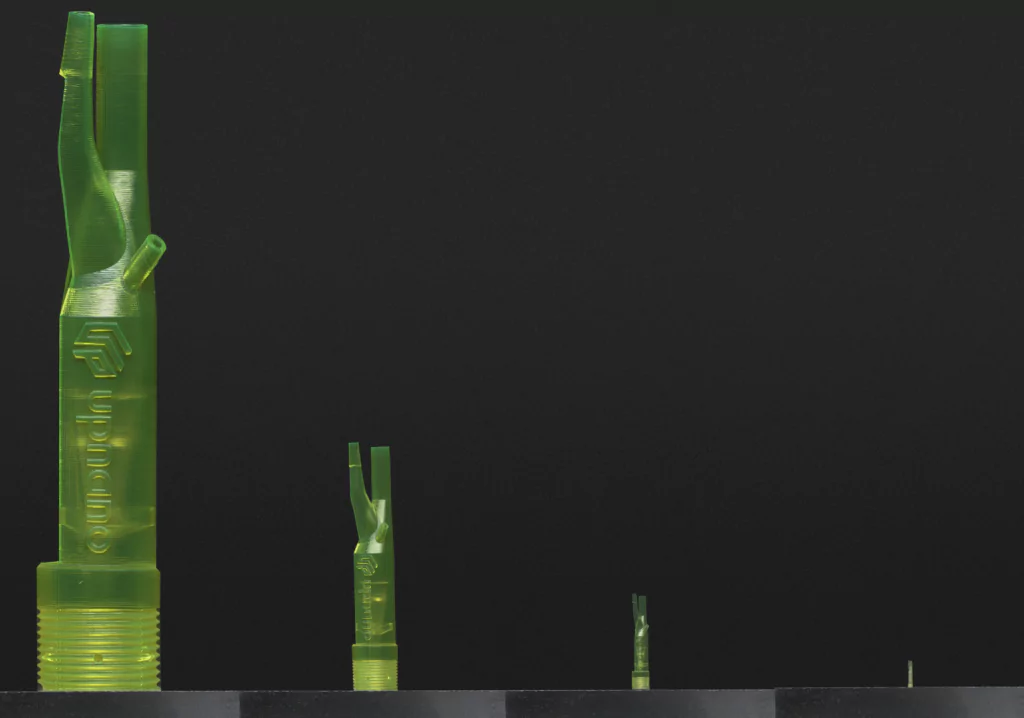

Unprecedented voxel throughput

The NanoOne 2PP 3D printer series has set a new standard in performance with one of the strongest femtosecond lasers available for any commercial 2PP system (1 watt), capable of operating at 1.6 Megavoxels/second with 16-bit precision. This makes it perfect for prototyping and smaller-scale batch production for our customers in industry and the academic world in their own facilities.

Now, the NanoPro VT elevates this performance further with an even more powerful 7-watt femtosecond laser, delivering an astonishing 32 Megavoxels/second with the same 16-bit precision. This advanced system is designed for our expert operators to seamlessly produce exclusive microparts for our customers 24/7, eliminating any hassle on their end. The shift from 780 nm to 515 nm laser wavelength on the NanoPro VT offers our customers enhanced resolution of microparts by further reducing the size of the voxel as well as expanding the range of transparent material options.

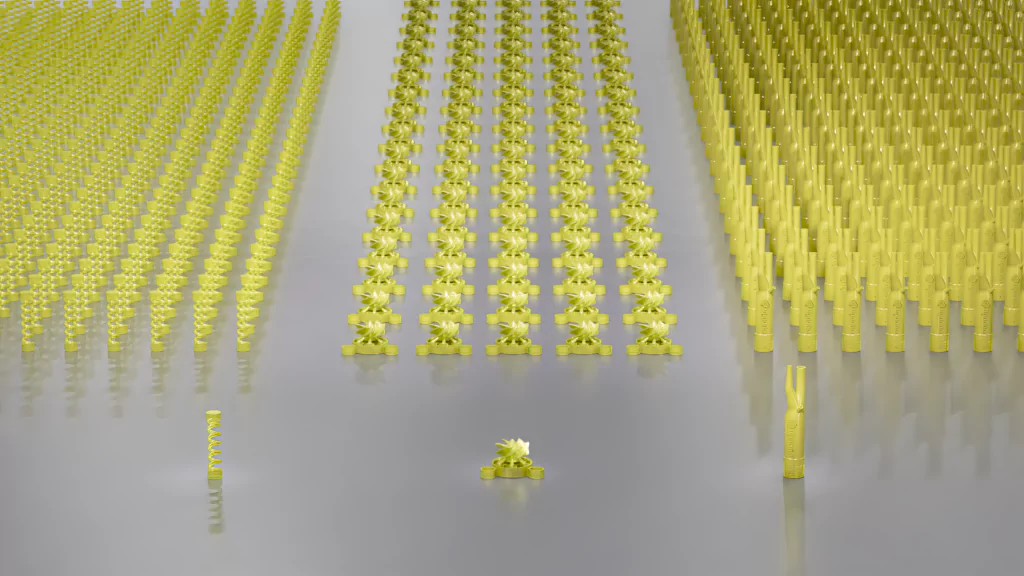

Record-breaking 2PP build volume

The NanoPro VT offers a full-area printable dimension of 200 x 200 x 50 mm (xyz), the largest substrate in the 2PP 3D-printing industry. This system can support fabrication on 8″ wafers, high-volume arrays and other surfaces such as customized or prefabricated devices. Combined with a part height of 50 mm, we’re taking 2PP 3D printing to a whole new level.

Maximizing efficiency through automatization and post processing steps

Sterile environment protection

The NanoPro VT operates with HEPA-filtered, temperature-controlled air and is mounted on a vibration-free industrial frame. To ensure contamination-free prints, our 2PP 3D printers are housed in a cleanroom environment on-site.