Applications

Use cases of NanoPro

Since industrial 2-photon polymerization (2PP) manufacturing was not available until the launch of our NanoPro service, most customer projects are in their early stages. Our team at UpNano provide support through all phases of our customer’s projects – from design to final serial production.

Bernhard Küenburg, CEO and Co-founder

As customer projects mature, production scales. UpNano ensures that your print capacity grows alongside your market demands, allowing your innovation to thrive without constraints.

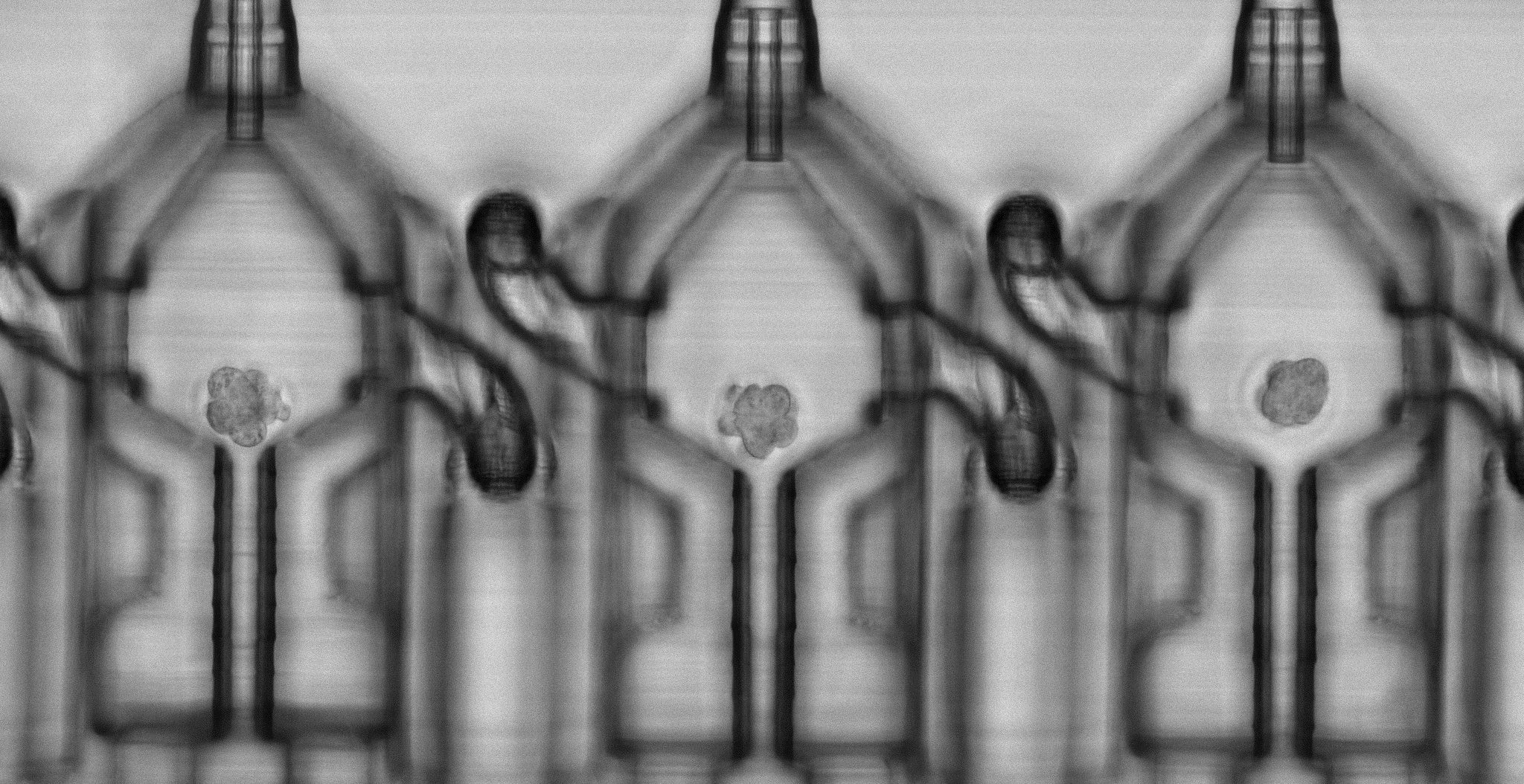

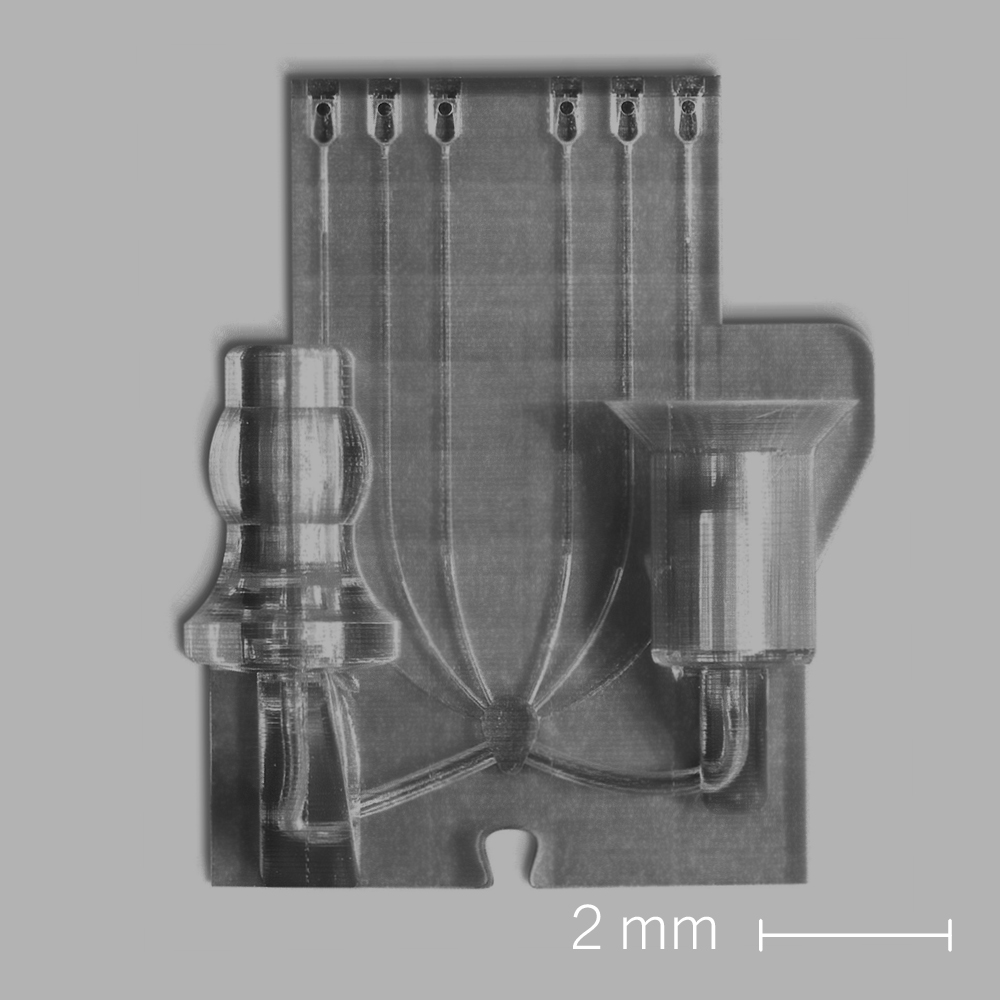

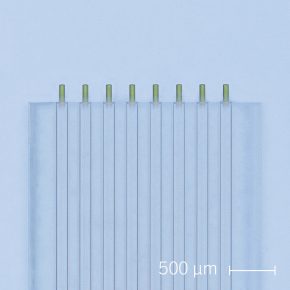

Microfluidics

A particularly delicate application within microfluidics is the field of in vitro fertilization (IVF). Fertilis has patented a unique environment for the critical life phase between fertilization and implantation of the embryo which requires specific holders and manifolds to be created featuring internal curved channels with a diameter of less than 50 µm. The only manufacturing technology that can produce structures with these requirements is 2PP 3D printing with a biocompatible material. With a global market of 10,000 – 15,000 IVF procedures every day, the need for mass production under strict quality control is a given. In a pilot phase, the first pregnancies through this method by Fertilis, are expected in late 2024, marking a significant milestone in the field.

Microsensoric

2PP 3D printed Microsensoric devices with integrated photonic circuits as well as thermochromic polymers or optical pH sensors, allow the development and production of intelligent wound dressings, which enable monitoring of wound healing processes without opening and removing the dressing. Due to the high number of wound dressings in a hospital setting, there is an urgent need for mass production.

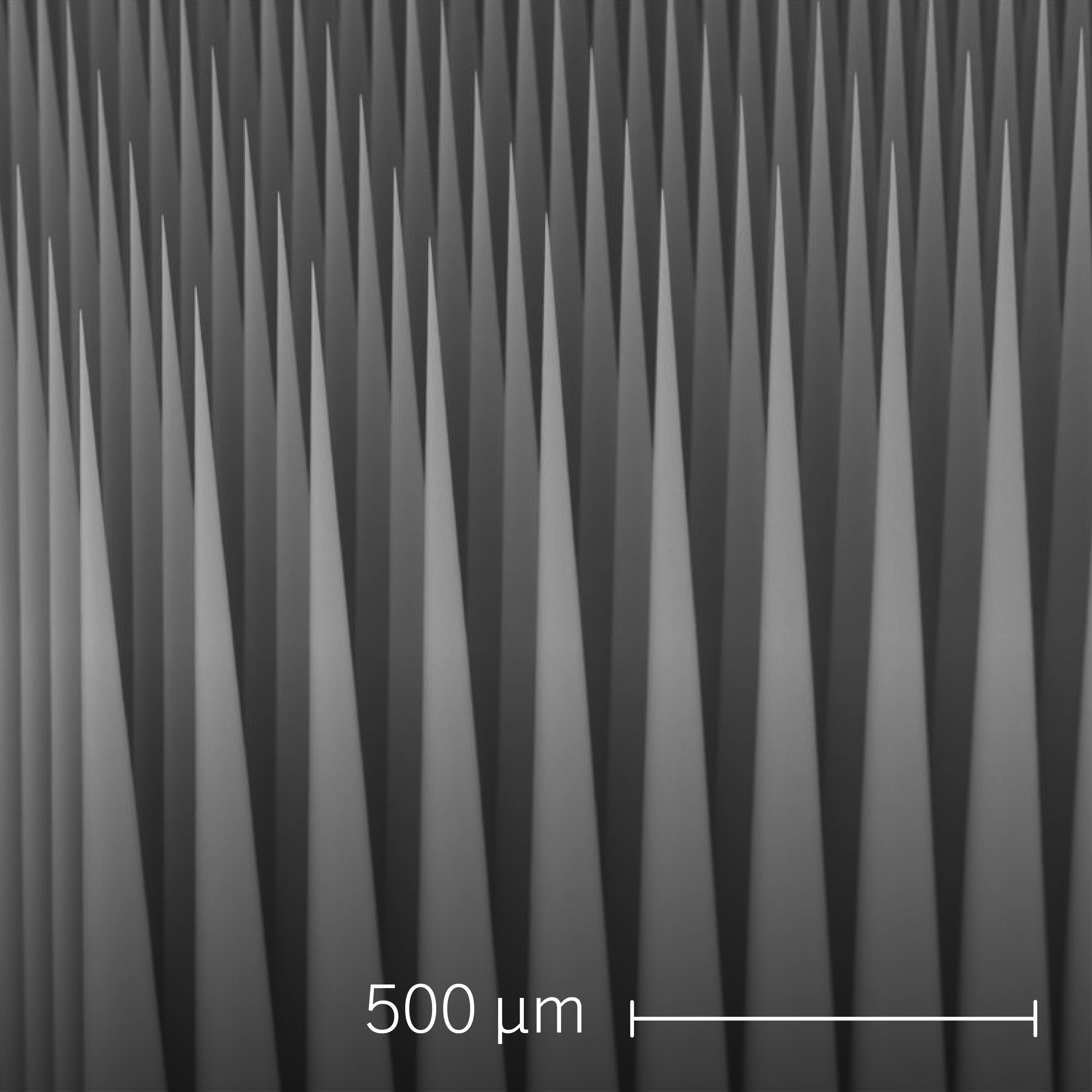

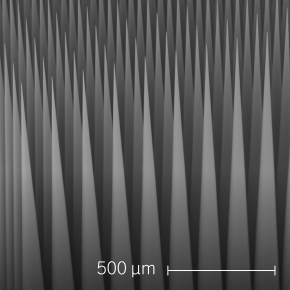

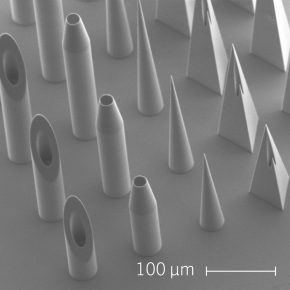

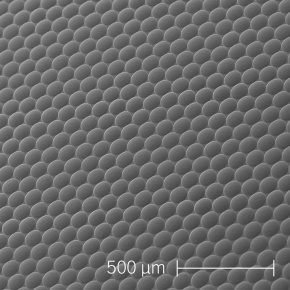

Microneedles

Application of modern vaccines, especially in the case of a pandemic, require updated technology that does not need support or supervision of medical staff. Microneedles are neither a needle nor a patch, they are a solution in between, allowing fast and non-invasive application of vaccines and eventually other drugs. This method of vaccine administration by global vaccination programs is growing and will require mass volumes of applicators, like these, which can now be fulfilled with NanoPro.

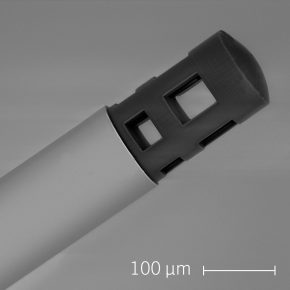

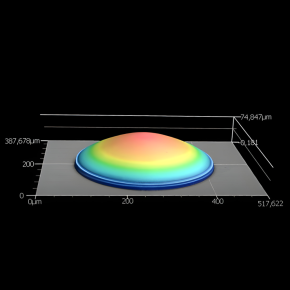

Micro-optics

Chip-scale optical sensing applications and interconnects for photonic integrated circuits or optical fibers often require precise reflective or transmissive micro-optics, such as microlenses. Typically, there is the need for active optical alignment during production, including the addition of elements such as spacers, alignment marks, or custom mounting structures. This kind of precision can only be solved with 2PP 3D printing technology. These elements are already in very high demand, seeing further rapid growth due to continued innovation in the field.

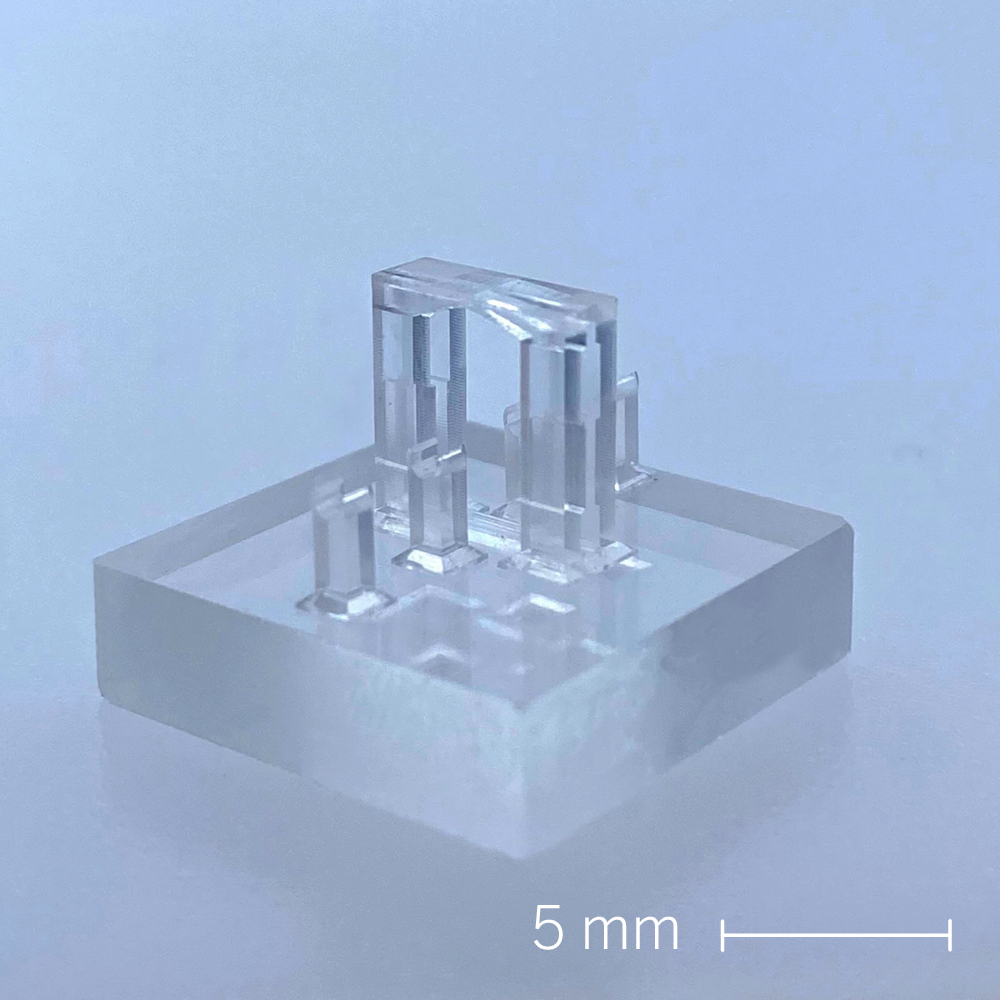

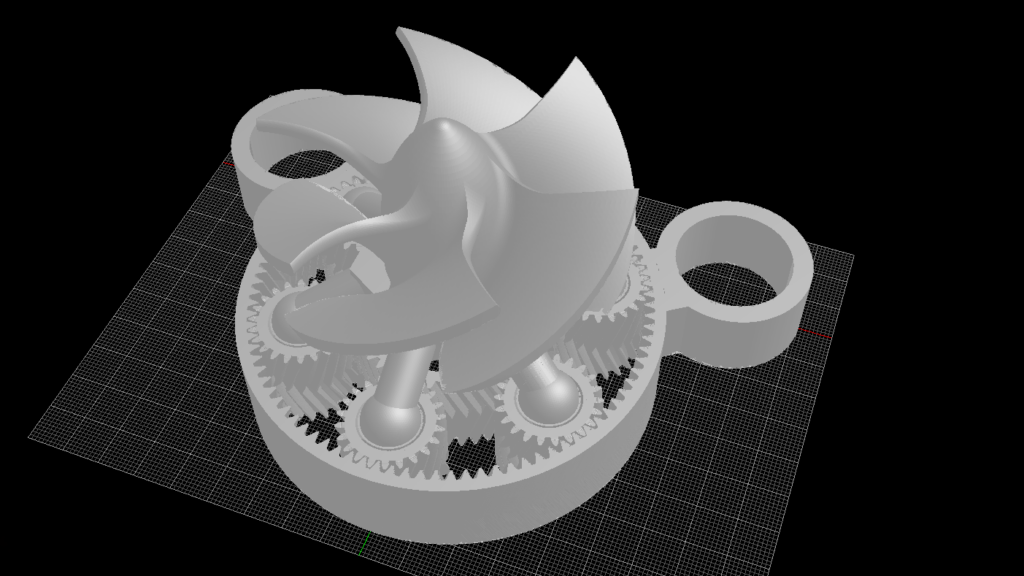

Polymer MEMs

Many industrial applications require micro-mechanical parts, micro-electro-mechanical systems (MEMs) or optical MEMs. Together with our customers, we have created optical actuators (such as submillimeter hexapods, which can precisely control optical mirrors), lab on a chip systems or simply complex micro-mechanical systems. The beauty of 2PP 3D print technology is demonstrated in the planetary gear box with a turbine on it, which is printed in one print job with full mechanical functionality, thus avoiding complex assembly steps.

Final printed part (with no assembly required) running with motor