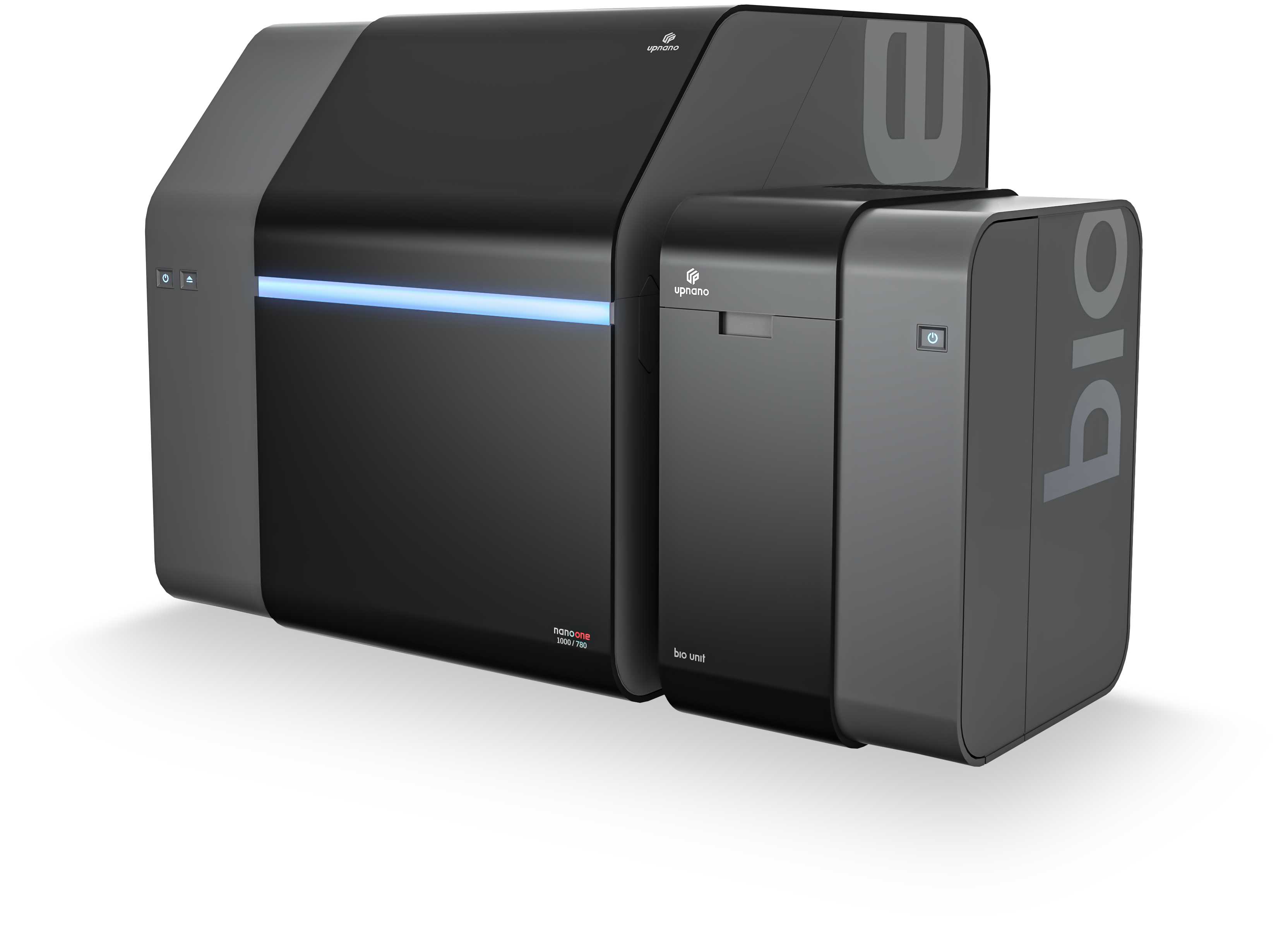

NanoOne bio

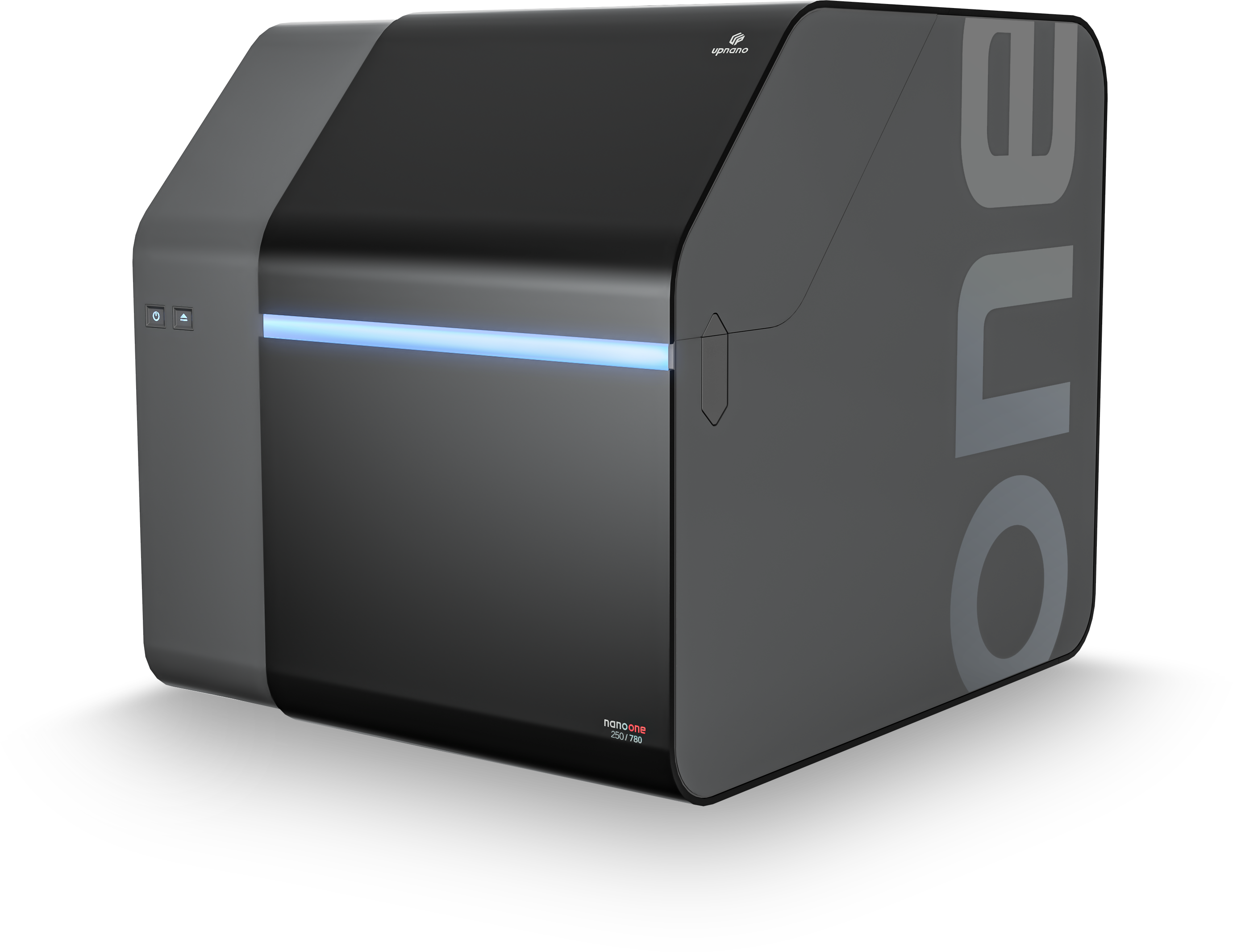

Experience the groundbreaking capabilities of the NanoOne bio package, the only 2PP printer with an integrated incubation system. The NanoOne’s bio variant combines the potential for biocompatible applications with the characteristic high precision and versatility of the NanoOne 1000, achieving unparalleled precision in 3D printing of structures in the presence of living cells. From creating cell models that mimic natural tissue topography to the sterile fabrication of cell scaffolds, NanoOne bio opens doors to a new era in biomedical research. Join us in shaping the future of bioprinting.

Average output power of the femtosecond laser

1000 mW*

Pulse length of the laser beam

90 fs

Included high-performance objectives

40x NA 1.4

20x NA 0.7

10x NA 0.4

10x NA 0.3

5x NA 0.25

Upgrade ability for additional objectives

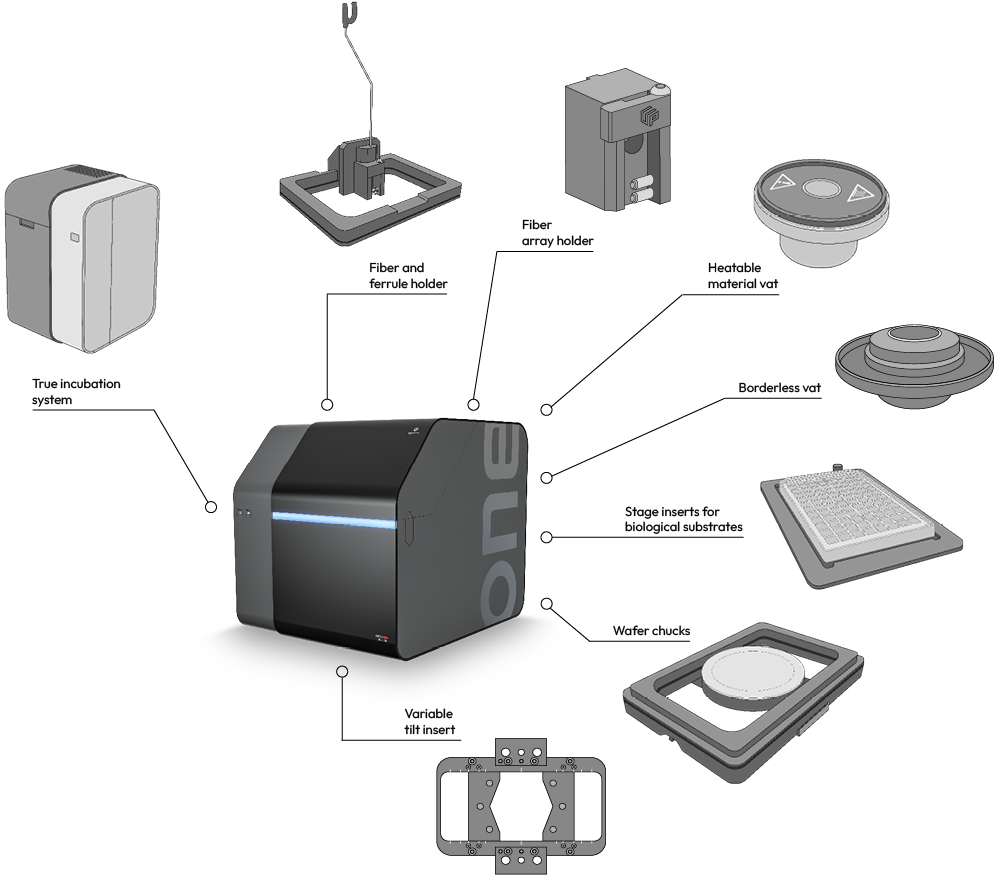

Customized beyond precise bioprinting

NanoOne systems offer both a standard configuration and the flexibility to customize with additional modules to meet specific application demands. Easily explore upgrade options to ensure your NanoOne bio package meets your requirements. These upgrades can be retrofitted at any time, ensuring your system evolves alongside your innovative manufacturing approaches. NanoOne Bio’s capabilities extend beyond bioprinting, making it versatile for various applications.

Design with a focus on biological applications

Cell-containing samples for three-dimensional in-vitro tests

Filter elements with defined pore sizes and gyroid structures

Barrier models with defined semi-permeability within microfluidic chips

Scaffold structures positioned in each individual well of a cell culture plate

Cell models mimicking natural tissue topography and microenvironment

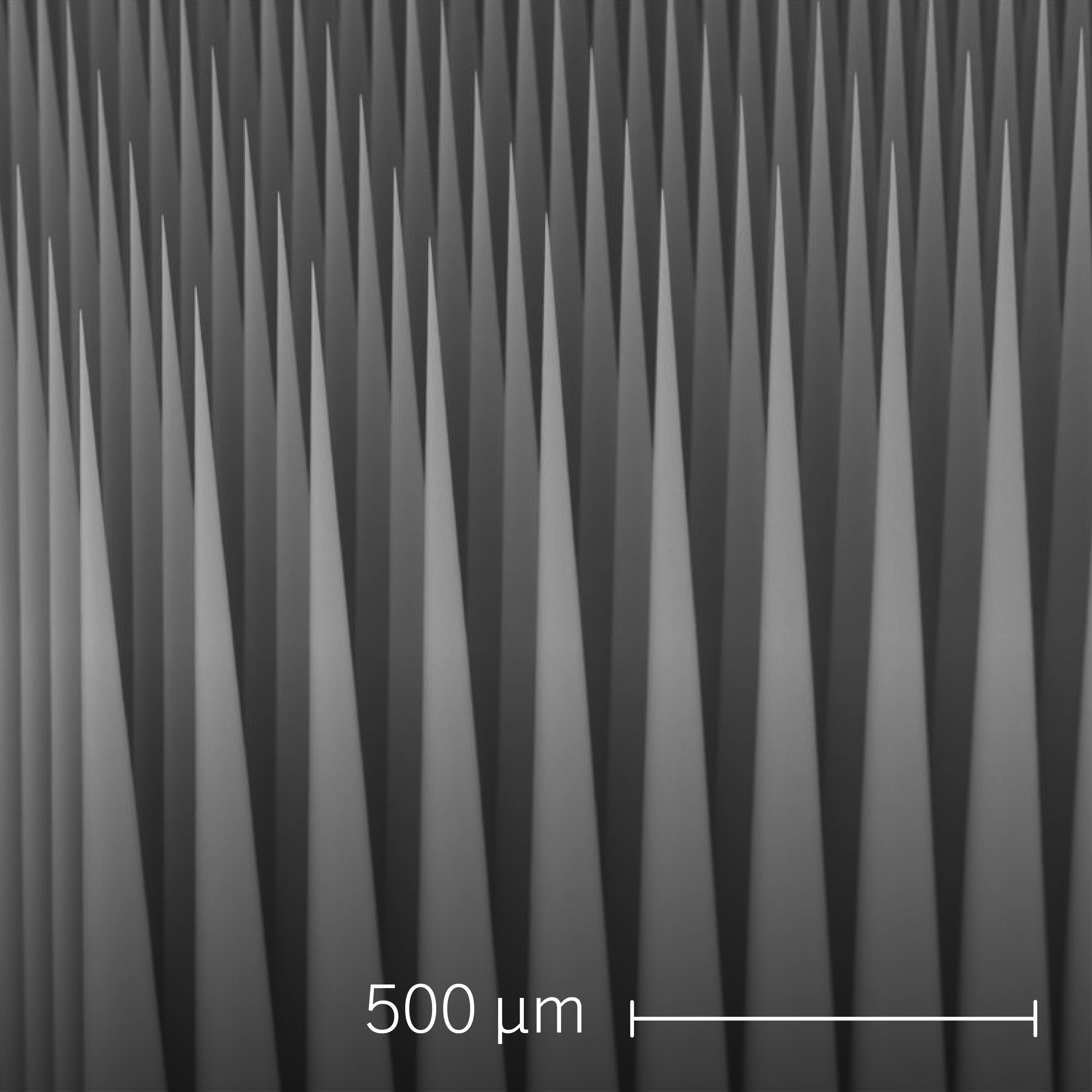

Medical devices such as implants or microneedle arrays

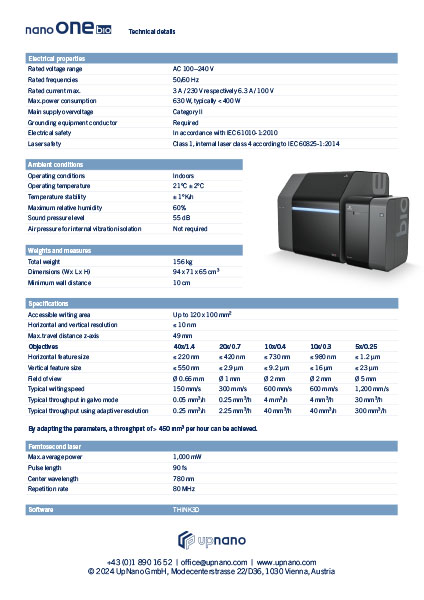

Specifications of the system

|

System type

|

Desktop multiphoton laser lithography system

|

|---|---|

|

Printing process

|

Layer-by-layer 2-photon polymerization

|

|

Light source

|

Femtosecond fiber laser

|

|

Laser wavelength

|

780 nm

|

|

Output power of femtosecond laser

|

1000 mW*

|

|

Scanner

|

Galvanometer scanner

|

|

Stage

|

Long-range piezo stage

|

|

Maximum travel range

|

Up to 120 x 100 x 49 mm

|

|

Stage address grid

|

10 nm

|

|

System dimensions

|

Benchtop system 94.0 x 71.0 x 65.0 cm³

|

|

Total weight

|

156 kg

|

*Power in the sample depends on the selected objective and is lower than the output power of the laser. For further information, ask the UpNano sales team.

Overview of NanoOne models

|

|

|

|

|

|

|---|---|---|---|---|

|

Output power of femtosecond laser

|

250 mW*

|

1000 mW*

|

1000 mW*

|

400 mW*

|

|

Laser wavelength

|

780 nm

|

780 nm

|

780 nm

|

515 nm

|

|

Pulse length

|

90 fs

|

90 fs

|

90 fs

|

90 fs

|

|

Standard objectives

|

40x NA 1.4

20x NA 0.7 10x NA 0.4 |

40x NA 1.4

20x NA 0.7 10x NA 0.4 5x NA 0.25 |

40x NA 1.4

20x NA 0.7 10x NA 0.4 10x NA 0.3 5x NA 0.25 |

40x NA 1.4

20x NA 0.7 10x NA 0.4 |

|

System dimensions

Total weight |

58.5 x 71.0 x 65.0 cm³

124 kg |

58.5 x 71.0 x 65.0 cm³

124 kg |

94.0 x 71.0 x 65.0 cm³

156 kg |

58.5 x 71.0 x 65.0 cm³

124 kg |

|

*Power in the sample depends on the selected objective and is lower than the output power of the laser. For further information, ask the UpNano sales team.

|

||||

|

System type

|

Desktop multiphoton laser lithography system

|

|---|---|

|

Printing process

|

Layer-by-layer 2-photon polymerization

|

|

Light source

|

Femtosecond fiber laser

|

|

Scanner

|

Galvanometer scanner

|

|

Stage

|

Long-range piezo stage

|

|

Maximum travel range

|

Up to 120 x 100 x 49 mm

|

|

Stage address grid

|

10 nm

|

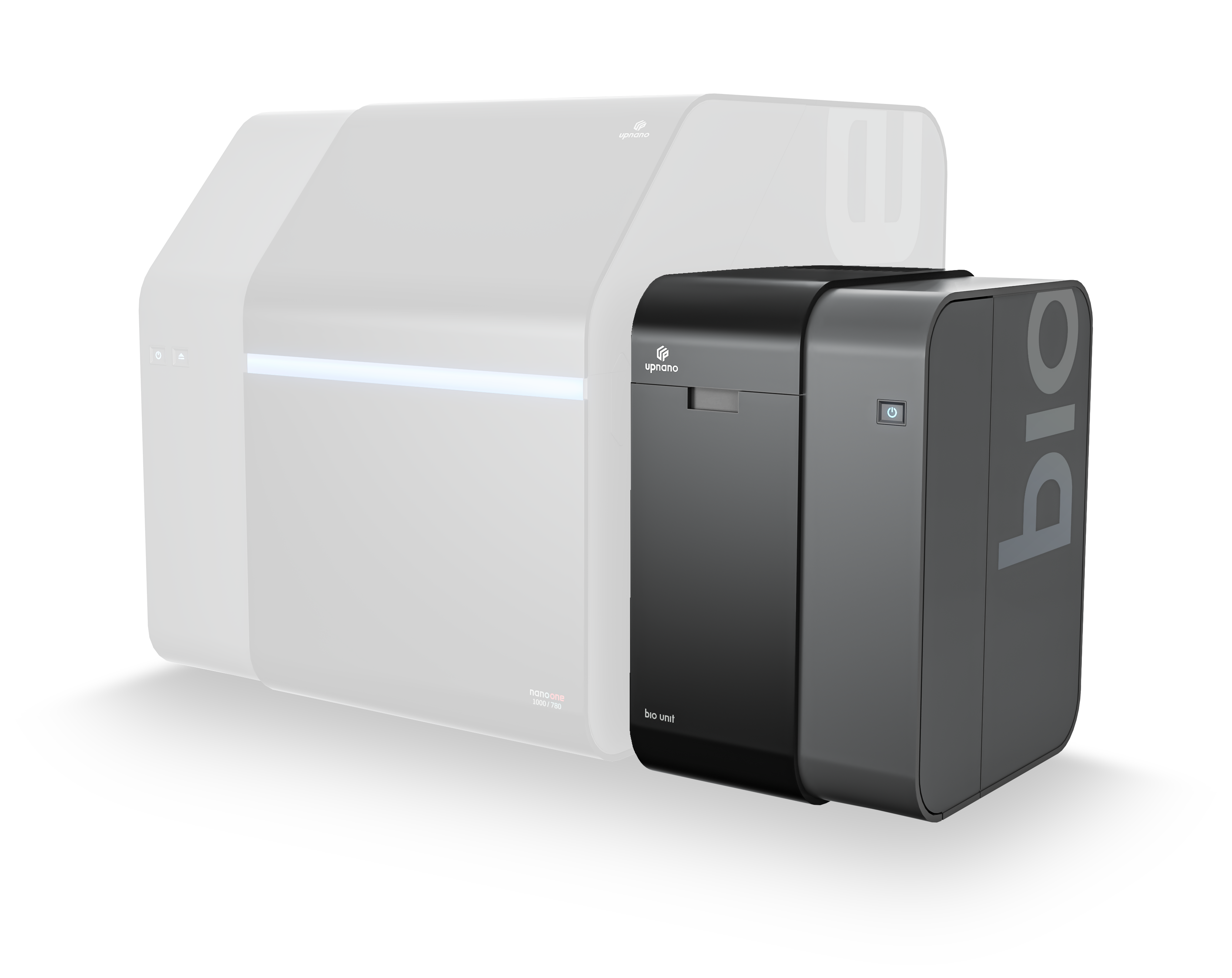

The only true incubation system for 2PP-3D printing systems

The UpNano BioUnit is the centerpiece of the NanoOne’s bio variant and an upgrade opportunity for all printing systems. It’s the only true incubation system for high-resolution 3D printing, providing a native, stress-free environment for the living cells during the printing process. The stage-top incubation system offers a plethora of features, allowing adjustments to match the preferred environmental conditions of the respective cell type and ensures these conditions during printing.

High-resolution bioprinting with living cells

Our comprehensive incubation system comprises of two controller units, a heating panel, and a CO2 gas incubation system. The gas incubation system provides a regulated gas atmosphere along with precise humidity levels within a continuous gas stream circulated through the incubation chamber. Meanwhile the heating panel maintains the ambient temperature required by the specific cell type, ensuring a native environment during the printing process and thus preserving cell viability.

Ambient temperature to 45°C ± 0.05°C

Actively humidified 20–99% ± 0.1%

CO₂ concentration 0–15%

Experience the future of bioprinting with NanoOne

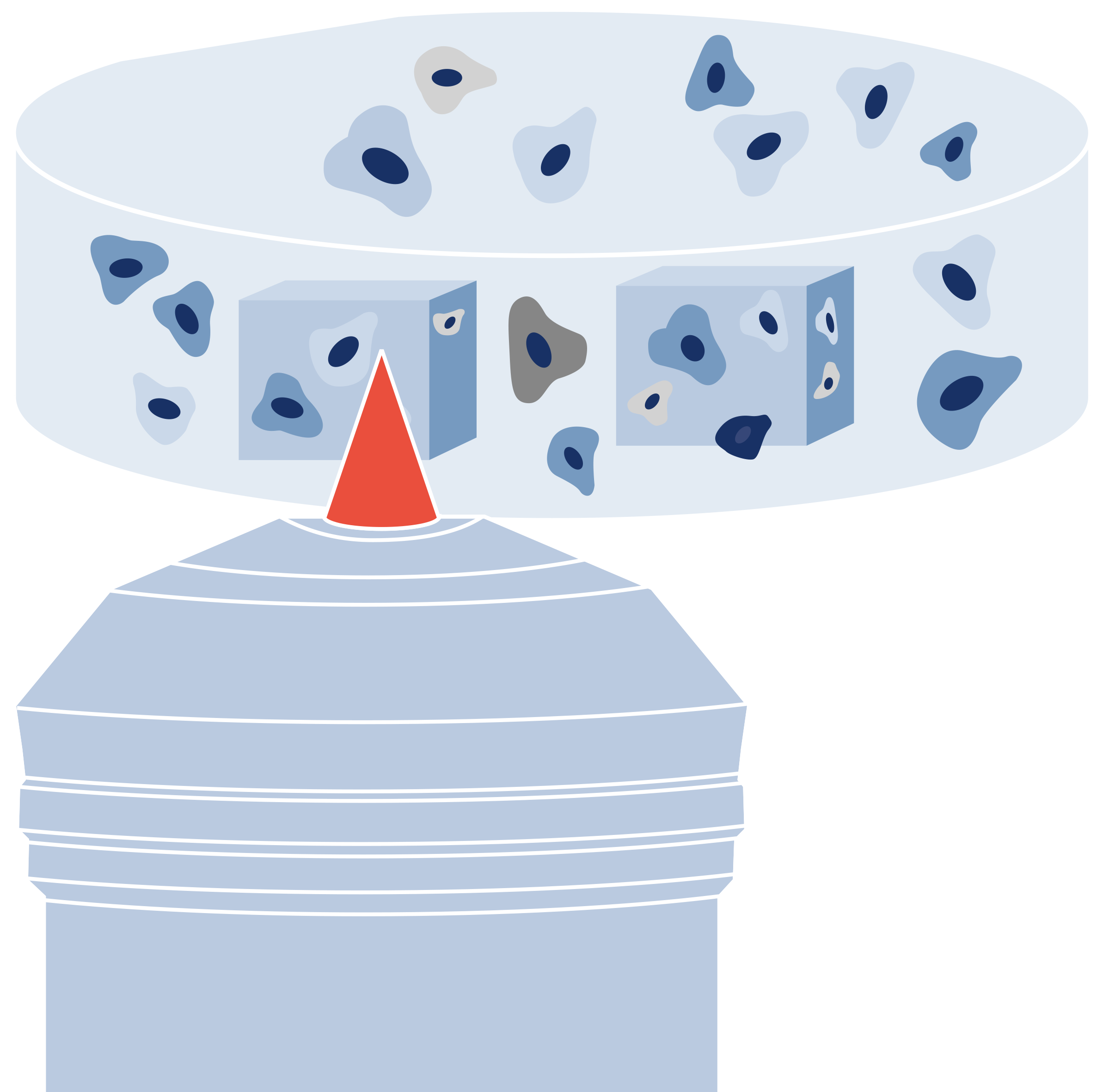

Direct printing of living cells for cutting-edge research, unrestricted substrate options, and precise control of environmental conditions for optimal cell viability.

High-resolution bioprinting with the NanoOne printing system enables direct printing of living cells. Cells embedded into the printing resin can be used for three-dimensional in-vitro cell tests and high-resolution 3D bioprinting, which have become increasingly important in cell culture, tissue regeneration and pharmaceutical research. There is hardly any restriction in the choice of substrate – cell culture plates, petri dishes or microfluidic chips with glass bottoms can be inserted into the system. In combination with the BioUnit native temperature, humidity, and CO2 conditions are maintained during the printing process, ensuring cell viability.

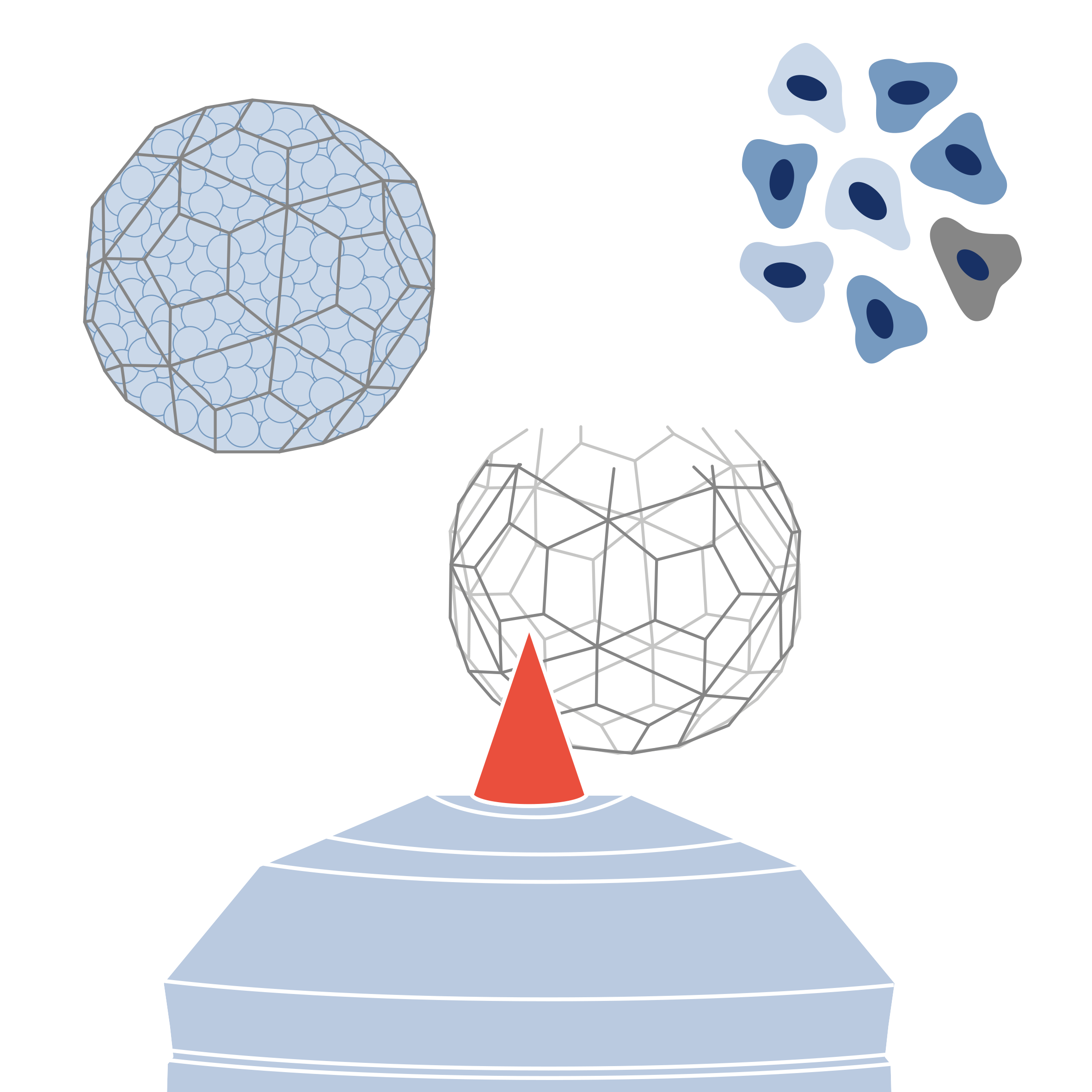

Revolutionize the manufacturing of 3D scaffold structures

Biocompatible resins, perfect for mimicking cellular microenvironments and setting new standards in preclinical research and therapeutic strategies.

Sterile-manufactured scaffolds with UpNano’s biocompatible resins enable the fabrication of structures and surface textures mimicking the microenvironment of cells. These three-dimensional culture approaches, along with the results obtained from them, are becoming increasingly important in preclinical research and will be groundbreaking for future therapeutic strategies. In addition to the BIO INX® biofunctional material portfolio, five UpNano resins have been certified as non-cytotoxic and highly biocompatible according to EN ISO 10992-5:2009. Furthermore, the UpOpto and UpFlow resins exhibit low fluorescence, making them advantageous for cell biological applications and microscopy.

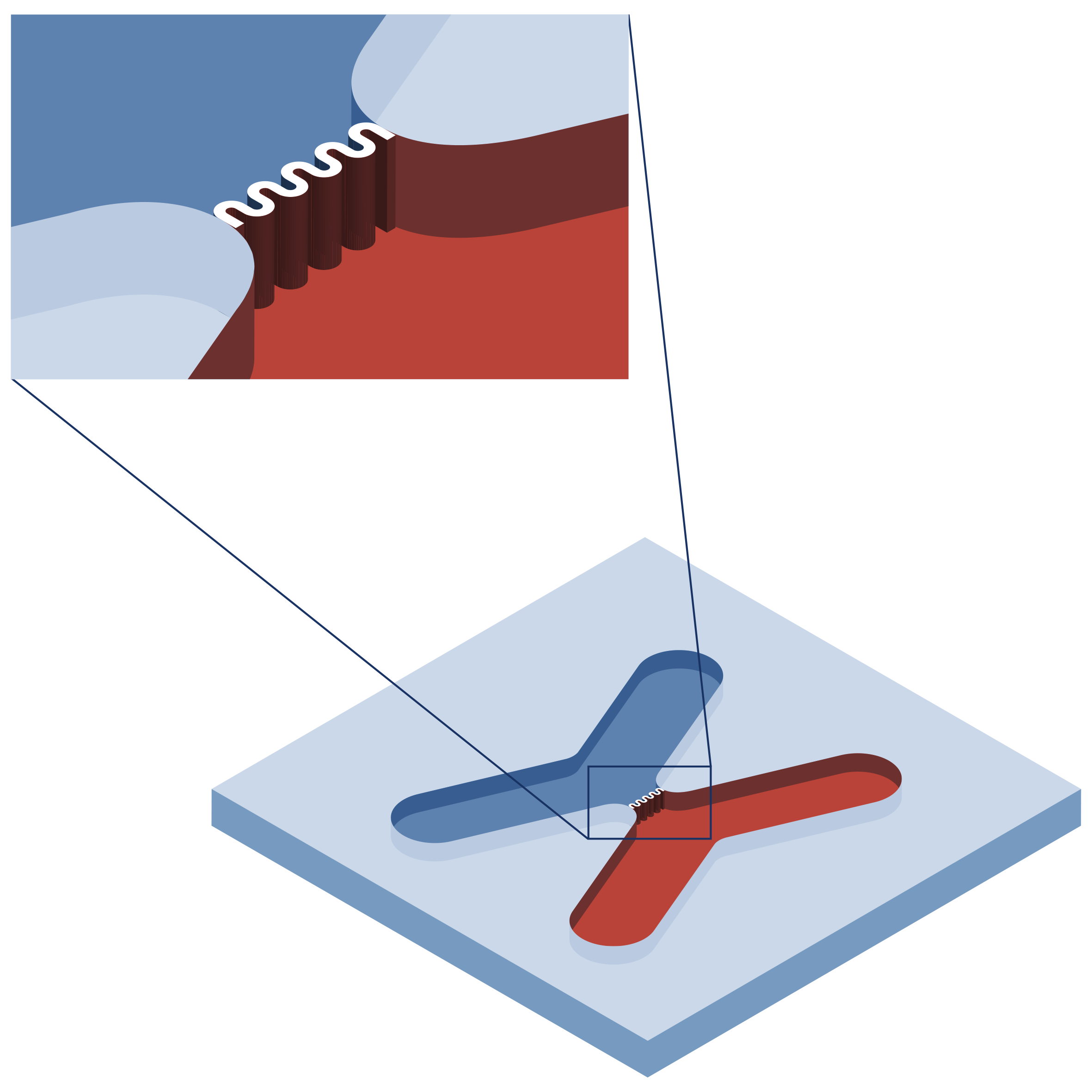

Rethinking production of microfluidic and microphysiological systems

UpNano’s dip-in free proprietary process unlocks new possibilities in 3D printing directly within a microfluidic chip or cell culture well.

This offers high-precision manufacturing for microfluidic and microphysiological systems. With this innovative approach, producing geometries within substrates, as well as entire chip designs with complex internal channel structures as small as 10 µm, has never been easier and safer for cells. This allows for contamination-free printing of elements such as separators, channels, membranes, or scaffolds, with the material prepared and post-processed under the cell culture hood.

Examples of compatible cell-culture substrates

Biocompatible 3D printing resins according to EN ISO 10993-5

In addition to a cell-compatible process, the choice of printing resin is crucial. With our collaboration with the Belgian company BIO INX®, we have developed a biofunctional material portfolio that is not only cell-compatible but also optimized for the NanoOne platform. Moreover, UpNano offers a portfolio of five biocompatible resins certified as non-cytotoxic according to EN ISO 10993-5:2009. Each of these resins, in addition to being biocompatible, has unique properties that highlight the wide range of possible applications. Choose UpNano for both cell compatibility and versatility in resin selection.

Get more information about our other 3D printers

Downloads

Please click image to download the document.