Hot Lithography®

Hot Lithography®

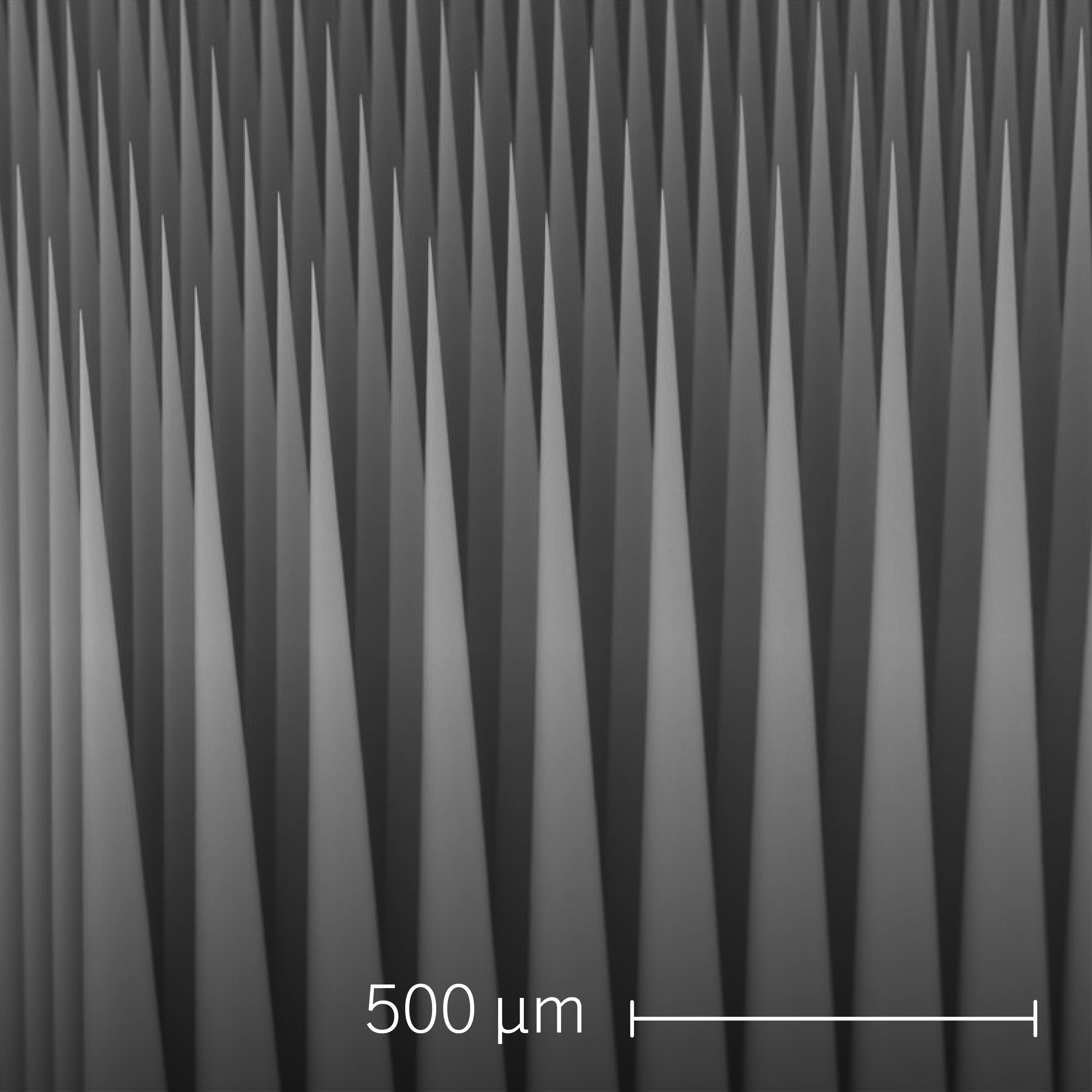

In the last years, Cubicure has emerged as a pioneer in lithographic printing of particularly tough and heat-resistant parts. Their patented process Hot Lithography® for the additive manufacturing of polymer parts revolutionizing the possibilities for high-resolution 3D printing. The aim of Cubicure is to produce polymer parts with exceptional impact strength and high heat deflection temperatures, while maintaining the highest possible surface quality. To achieve these properties, highly viscous materials are needed, which can be challenging to process – especially for precision applications.

Hot Lithography® addresses this challenge with its unique heating mechanism, allowing for the processing of high-molecular chemical substances for a high-precision 3D printing process for the first time and consequently establishes parts with unexpected material quality. The multiple patented process has already facilitated the development of numerous new photoresins. In combination with the flexibility of additive manufacturing, components can be produced with unprecedented flexibility and efficiency, meeting the demands of modern manufacturing.

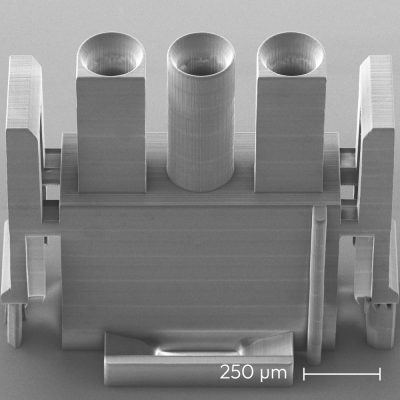

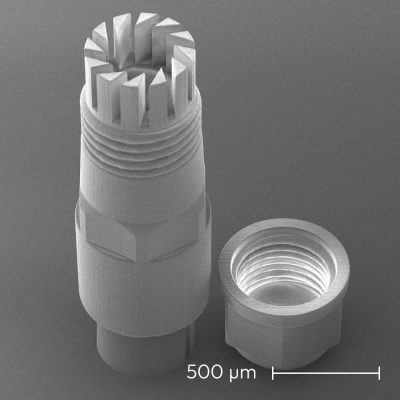

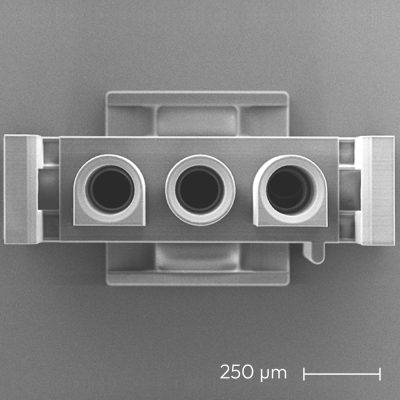

Components produced with Hot Lithography® exhibit exceptional temperature and long-term resistance, making them ideal for industrial applications, such as in electronics or medical technology.

2PP Hot Lithography®

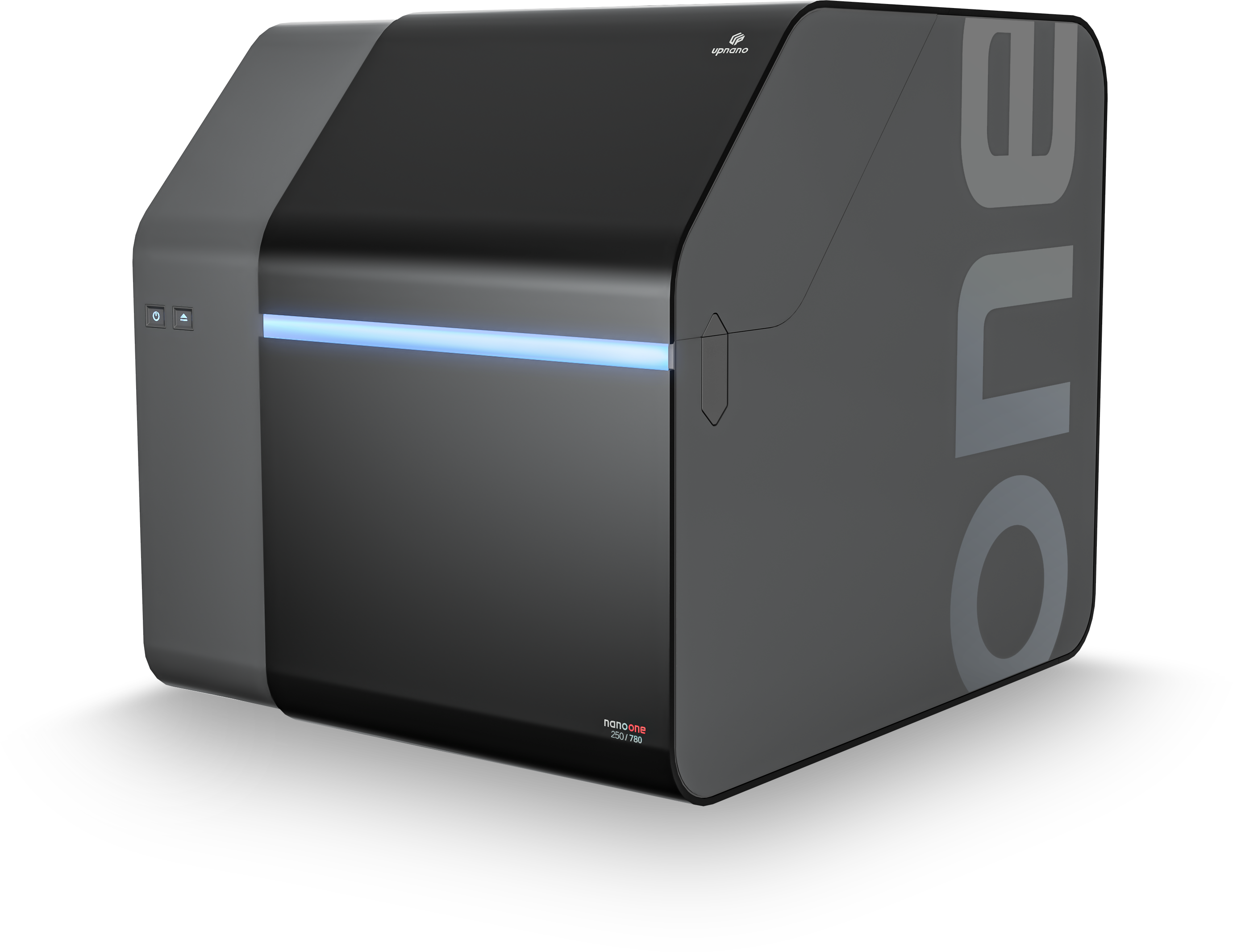

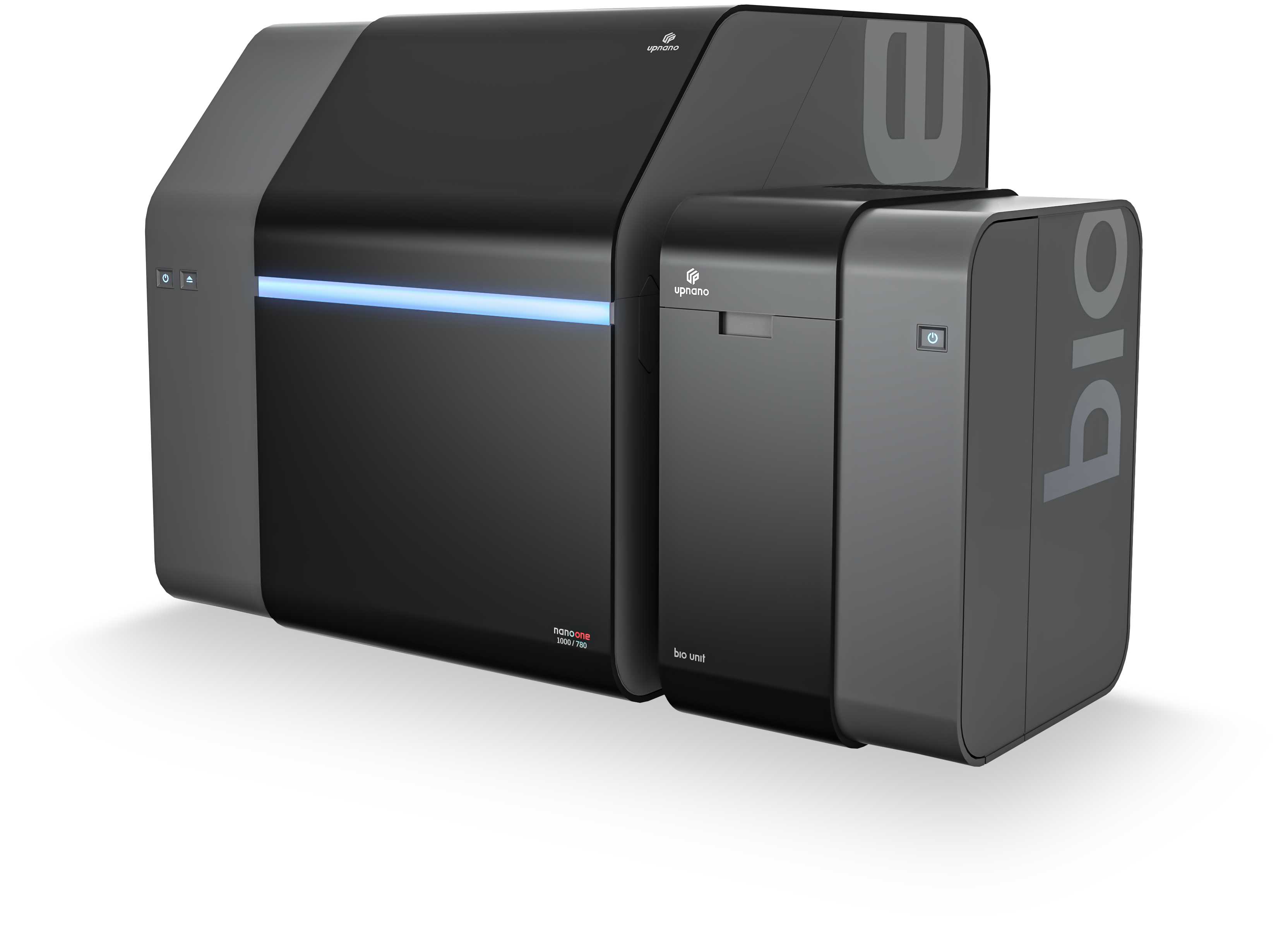

UpNano has entered into a licensing agreement for the patented Hot Lithography® technology and seamlessly integrated it into the 2PP (2-photon polymerization) process of their printing platform through close cooperation with Cubicure. The primary objective was to establish Hot Lithography® as a retrofittable module, enabling not only new printing systems but also all existing systems in the field to benefit from this cutting-edge technology.

Beyond simply adapting the Hot Lithography® hardware for 2PP printing, the collaboration delved into the development of a 2PP resin with unique and exceptional characteristics. Leveraging Cubicure’s expertise in tailoring the molecular weight, functionality, and chemical nature of resins, in tandem with UpNano’s competence in photochemical processes, laid the groundwork for the joint development of the 2PP resin UpThermo. This material, now a standard offering on UpNano printing systems, represents a significant milestone achieved through collaborative innovation and technological advancement.