First Ultrafast Nano 3D Printer Installed at Medical University of Vienna

TU Wien and UpNano provide advanced technology for medical research

Vienna, 14 November 2019 – The first ultrafast nano 3D printer NanoOne has been installed and successfully put into operation at Medical University of Vienna in October as part of a project called Additive Manufacturing for Medical Research M3dRES). The technology for the printer is from Austria and was developed by scientists at the Vienna University of Technology (TU Wien) working with UpNano, a spinoff of the university. It sets an entirely new benchmark in high-resolution 3D printing.

New dimensions in nano 3D printing

“NanoOne is the only 3D printing system capable of creating our highly complex test pieces in the sub-micrometer range at this speed,” explains Dr. Francesco Moscato, Head of M3dRES, following the system’s launch. The Center for Medical Physics and Biomedical Engineering at Medical University of Vienna will use the printer to provide micro- and meso-scale components to all of the departments conducting research. For instance, one such project is on the topic of surfaces intended to prevent bacterial colonization and thus reduce the use of antibiotics.

Award-winning technology

Peter Gruber, Head of Technology and Founder of UpNano, provides further clarification of NanoOne’s precision, “Using this printer, we can print a complexly modeled castle no larger than 0.2 millimeters in size that fits on the tip of a pencil. The castle includes all of the structural details including load-bearing columns with a diameter of less than one-thousandths of a millimeter.” In 2017, UpNano already won first place at the Wiki Science Competition with the project dubbed “Castle on a Pencil Tip.”

Small, fast, powerful

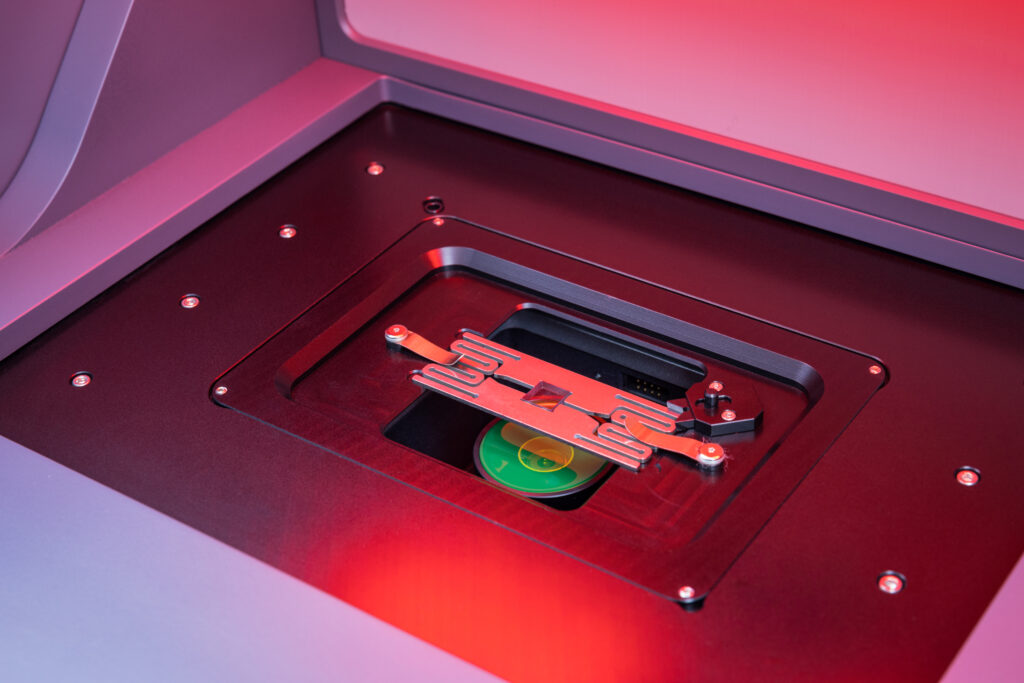

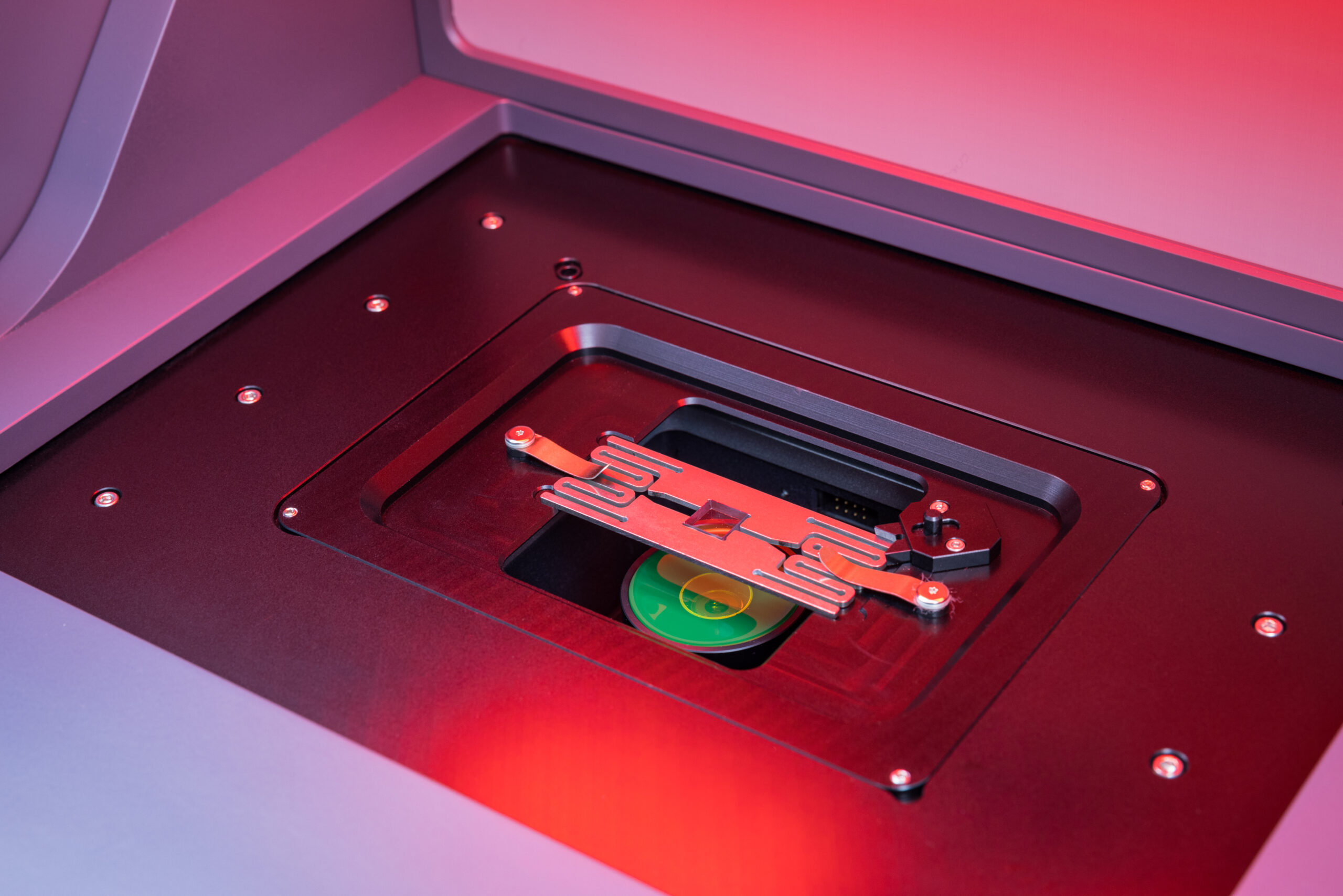

Modern research requires ever smaller and more precise components which traditional production technologies can hardly manage to produce efficiently. To achieve greater precision, UpNano relies on a method called two-photon polymerization (2PP). An ultrafast laser pulse hardens photopolymers at any desired point in space. This method makes it possible for NanoOne structures to be printed in a size range from 100 nanometers to 10 millimeters.

With NanoOne, the model that is ready for series production, UpNano also managed to increase the printing speed of the 2PP 3D printing technology to up to 20 mm3/h, making production of micro-components commercially viable for the first time. At the same time, the system has been optimized to fit on a tabletop in the laboratory. Additionally, an incubator can also be connected to NanoOne making it possible to print biomaterials and mixtures of polymers and living cells directly.

Medical University of Vienna, M3dRes

Under the leadership of Medical University of Vienna, the M3dRES project aims to create an infrastructure to promote the benefits of 3D printing (e.g. for manufacturing “customized” medical devices, for medical imaging and diagnostics, and for tissue engineering and regenerative medicine) working in close cooperation with medical institutions. Another goal of the project is to augment the current body of expertise in Austria in the direction of medical applications for 3D printing. The project encompasses devices used for various materials and part sizes (polymer, metal, ceramic, nano and bio printers) and software for collecting medical imaging and designing technical constructions. The project is supported by the Austrian Research Promotion Agency (Forschungsförderungsgesellschaft, or FFG).

Downloads

Please click image to show high-resolution file.