Exceptional Versatile & Innovative Printing-System Successfully Established in Both, Industry and Academia

Successful sales demonstrate the potential of a high-end 2PP 3D-printing system to meet a wide range of customer demands

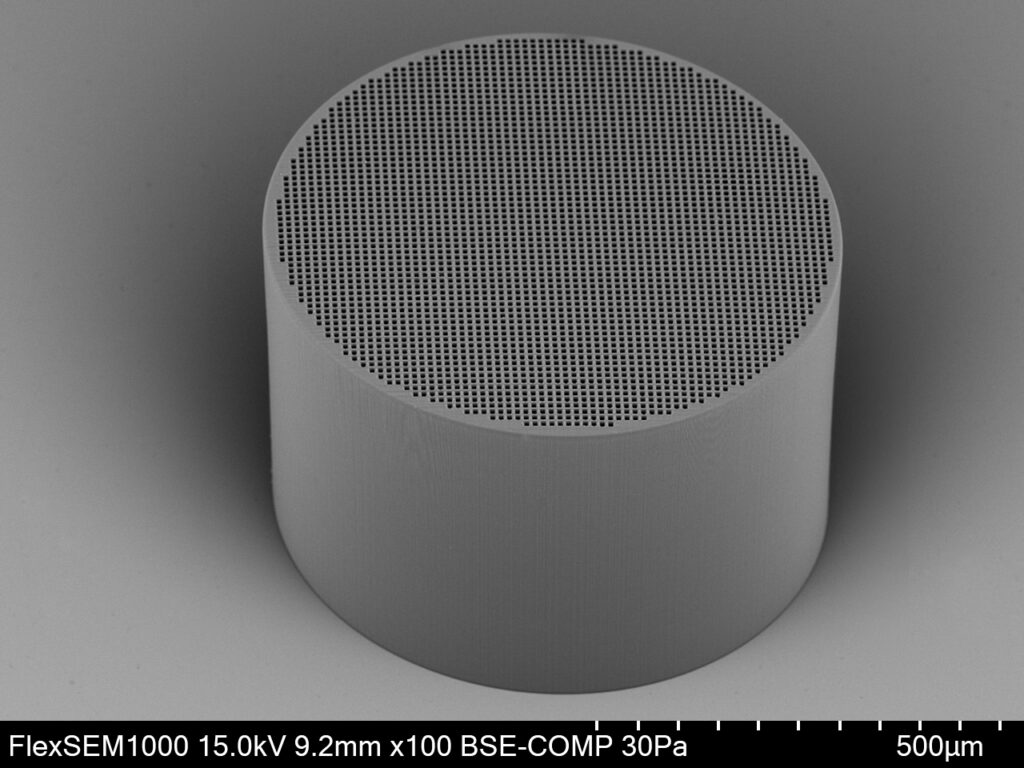

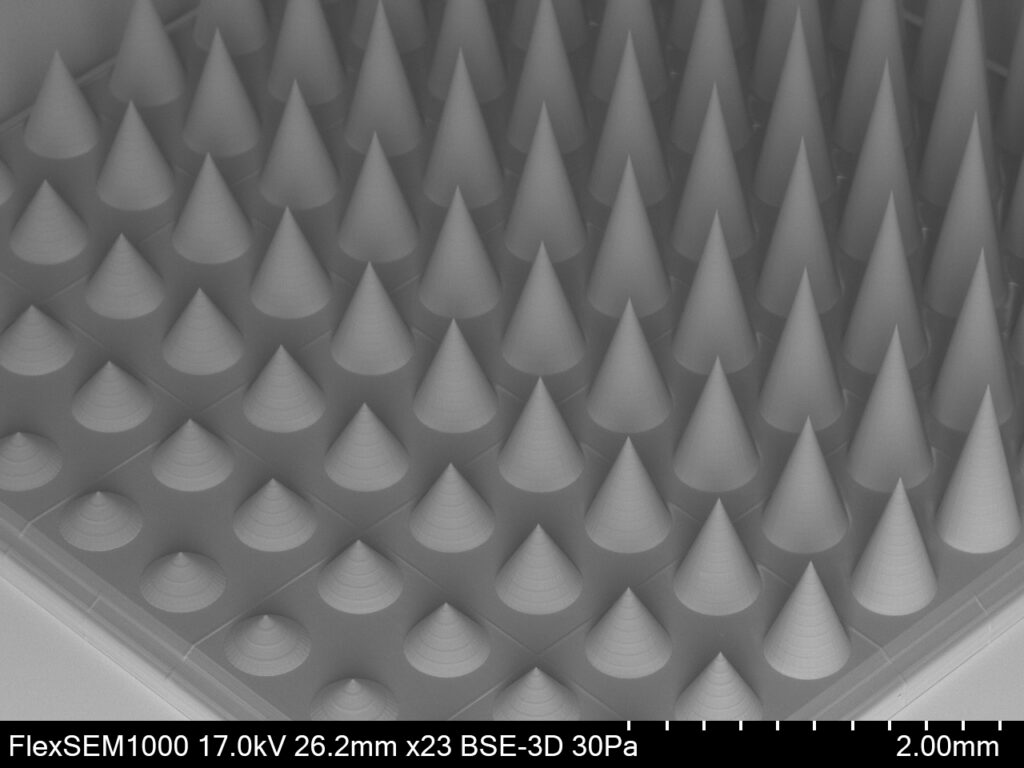

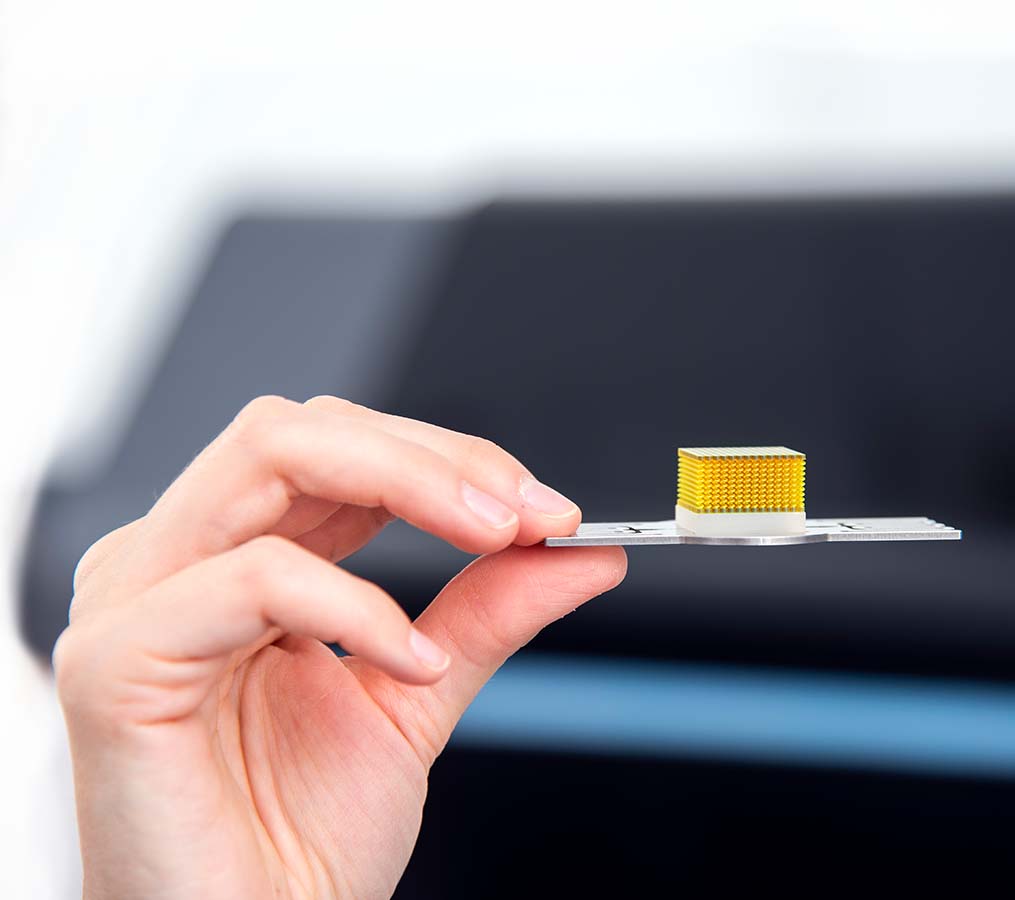

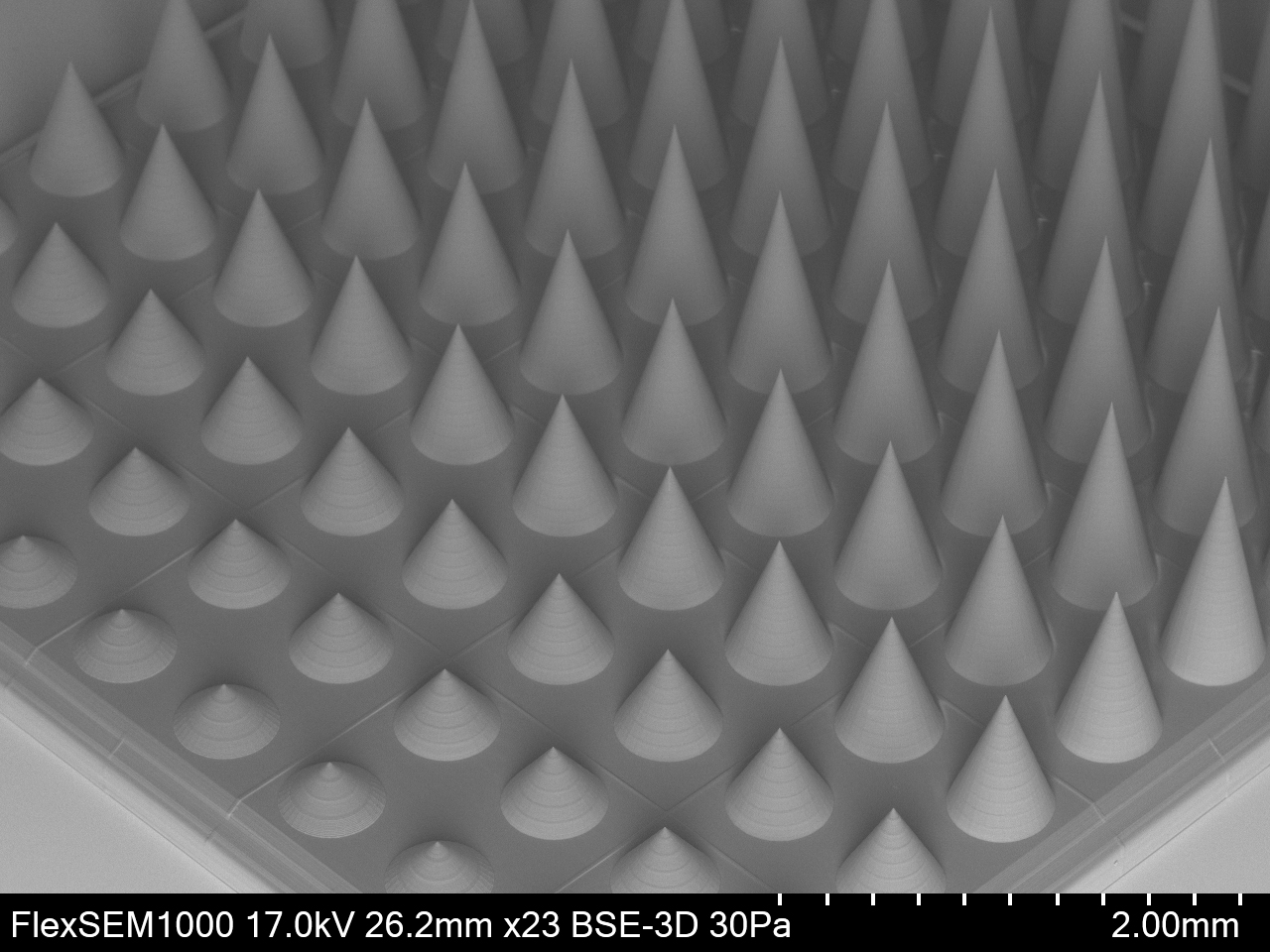

Vienna, Austria, 12th January 2021 – An innovative 2PP 3D-printing system that is capable of manufacturing across twelve orders of magnitude with exceptional speed has hit the market with great success, enabling fabrication of polymeric microparts from the nano to centimeter range. Several customers from industry and academia recently bought the NanoOne system by UpNano GmbH from Vienna (Austria), a spin-out of the TU Wien. Thanks to the versatility of the machine’s design all orders were individually tuned to customers’ specifications. Especially strong assets of the NanoOne are a high-power laser, an optimized optical pathway, the patented adaptive resolution technology and purpose developed algorithms for laser scanning. In the wake of this successful market entry the company also doubles the floor space in its Vienna headquarter and appointed a new Head of Global Sales, who has a proven track record in the industry.

2-photon polymerization (2PP) 3D-printing is an ultra-precise production technology at the edge of the physically possible. It enables companies to manufacture parts that were, literally, unthinkable a few years ago. At the same time, it is a highly sought-after technology in academic research. So far very few 2PP 3D-printing systems were able to meet the requirements of both domains, industry and academia. However, recent sales of the NanoOne-System by UpNano demonstrate that one highly innovative and versatile system can in fact fulfill a wide range of different specifications.

New Customer. New Material.

A European company now benefits from this versatility. Specialized in optical applications, the company recently was looking for a 2PP 3D-printing system that would be able to manufacture highly transparent components. The high-powered laser of the NanoOne not only allowed to deliver the necessary energy to polymerize this specific material, but UpNano also engaged a team of in-house specialists to develop the material in accordance with exact customer requirements. Bernhard Küenburg, CEO of UpNano, comments on the successful cooperation and deal: “The NanoOne convinces with an innovative adaptive resolution technology that together with an optimized optical path and smart algorithms utilizes the full power of our exceptionally strong laser. All this allows us to add specific functionalities to the system that meet individual customer requests such as the ones of our industry partners.” Also, the University of Freiburg in Germany decided recently to purchase a NanoOne demonstrating the appeal of the device for industry and academia alike. The university will exploit the potential of the printing-system especially in the material sciences including guest particles that require a high versatility and adaptability of 3D-printing processes.

Another university in the D-A-CH-Region as well as in Scandinavia placed orders for a NanoOne system a few weeks ago, following competitive tender procedures. However, their motivation to opt for this system was mainly driven by financial constrains that are quite common in the academic domain. A more basic version of the NanoOne was able to meet those expectations as well as all technical specifications requested by the cutting-edge research groups for which these systems have been acquired.

Strong Sales. Strong Team.

With such recognition of the NanoOne’s advantages by industry and academia alike, it comes as no surprise that the company currently doubles its space for offices, R&D and production at its Vienna headquarter. It also strengthened their sales team already. By appointing Henrik Åkesson as Head of Global Sales for UpNano, the company succeeded in winning the support of one of the most seasoned sales professionals in the 3D-printing industry. Henrik Åkesson on his new responsibility: “UpNano not only offers the best technology for speedy 2PP 3D-printing over a wide range of dimensions, but it also benefits from a highly motivated and innovative team. And it is both that we offer our customers – state-of-the-art printing systems and services, that helps customers to really get the best out of these machines. It is a great pleasure and honor to be part of this highly spirited team and to demonstrate to the market what 2PP 3D-printing can achieve, when knowledge and motivation are at the top of their league.”

Images available upon request or at the download section below.

Downloads

Please click image to show high-resolution file.