Applications

Breaking the barriers of nano- and microfabrication

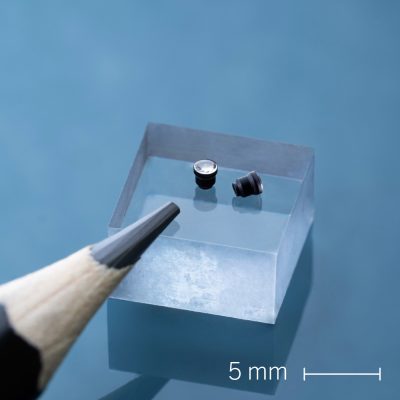

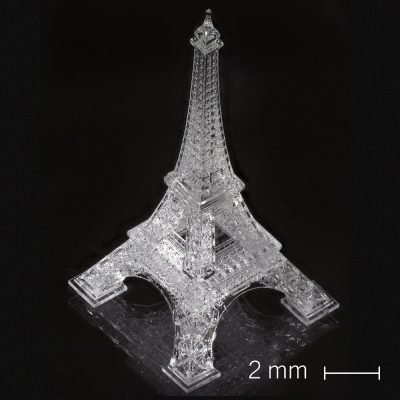

At UpNano, we offer a solution that significantly reduces production times and unit costs for microparts, all while maintaining resolution and tolerances. The versatile technology, based on multiphoton lithography, allows for the manufacturing of highest precision components with structural details below 100 nm and macroscopic microparts in the centimeter range. With a writing speed of up to 1,000 mm/s and a throughput of up to >450 mm³/h, NanoOne combines high performance with a user-friendly, fast process.

Research

Explore the future of scientific and industrial R&D with UpNano’s revolutionary 2PP-based microfabrication platform, driving innovation and sparking creativity across diverse research fields.

Scientific and industrial R&D

In the realm of research and development, UpNano’s 2PP-based microfabrication platform has emerged as a pivotal tool. The UpNano 3D printing systems are catalysts for new applications and innovative developments, serving as a driving force across various scientific and industrial research facilities. Their exceptional versatility, compatibility with a wide range of printable materials, and user-friendly software tools spark creativity and facilitate pioneering concepts.

Mastering and batch production

Unlocking the potential of innovative research, our mastering and batch production solutions ensure a seamless transition from lab to manufacturing, delivering unmatched efficiency and precision.

Scalable production

To transition the innovative approaches from research labs in science and industry from the laboratory benches to manufacturing halls worldwide, production time and reproducibility are crucial factors. These are two points that distinguish all UpNano printing systems from others. Whether it’s the cost-effective production of product batches or the manufacturing of mold or master structures for various high-volume replication processes, UpNano products are the right choice.

Serial production

UpNano’s manufacturing concepts comply with industry requirements and quality standards, establishing a 2PP-based method as a new production technology in mass manufacturing.

Production standard

Our printing systems put an end to the notion that “2PP printing is inherently slow”. Our innovative and patented printing process allows for the seamless transition of innovative products and applications into serial production.

Sophie Zagiczek, Application project coordinator

“Our customers’ diverse applications constantly inspire us. We have a strong conviction that 2PP-3D printing holds immense value for countless industries, and we’re excited to collaborate with our customers in exploring these exciting possibilities.”

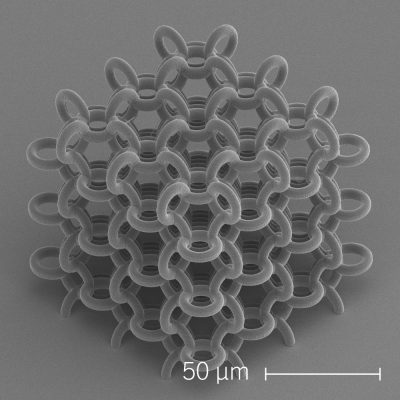

Material science

Open 3D printing platform for novel material development and the production of micron and sub-micron scale structures.

- Open system allowing users to conduct material development and discovery

- VAT printing setup enables the use of all different kind of resins

- Different VAT sizes provide freedom in substrate choice

- Dip-in free printing protects high-precision objectives and optics at all times

- High-performance laser provides sufficient power to polymerize specialized resins

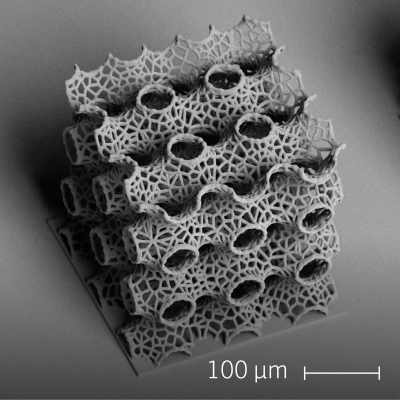

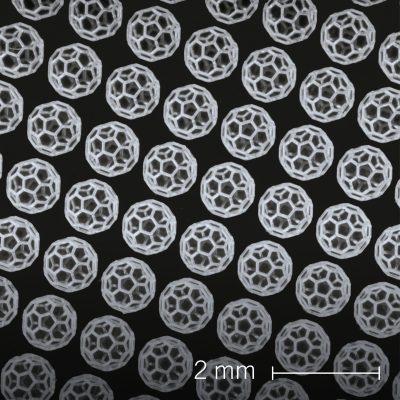

Experience a versatile platform for advanced material science at the sub-micron level. It offers extensive opportunities for material testing and fabrication. With various VAT sizes available, tailored to accommodate different volumes of liquid resin, UpNano’s printing system is ideal for processing metamaterials and creating architecture geometries. The VAT printing mode combined with 2PP is unique and facilitates a diverse range of resins while simultaneously protecting sensitive optics. Additionally, by incorporating a high-performance laser, this platform provides enough power to polymerize even the most unique resins, unlocking new possibilities in material development.

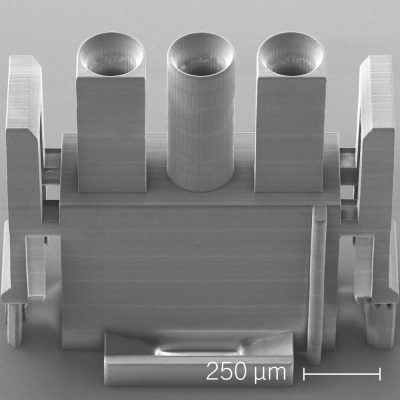

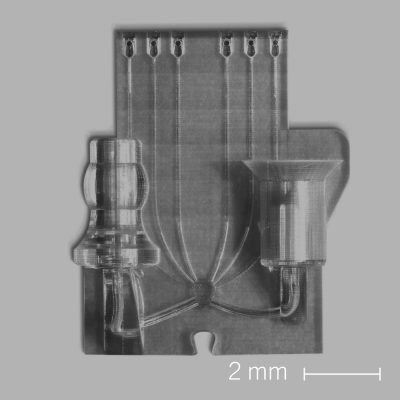

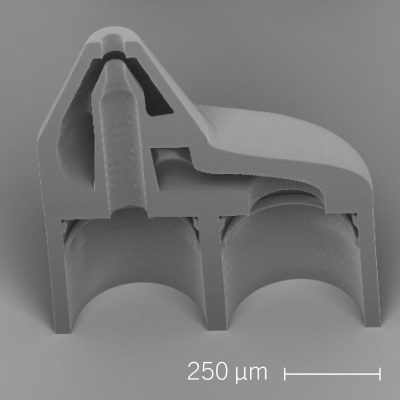

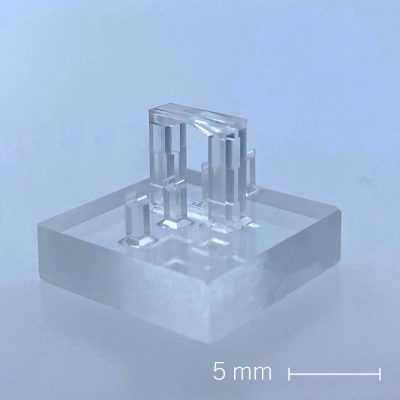

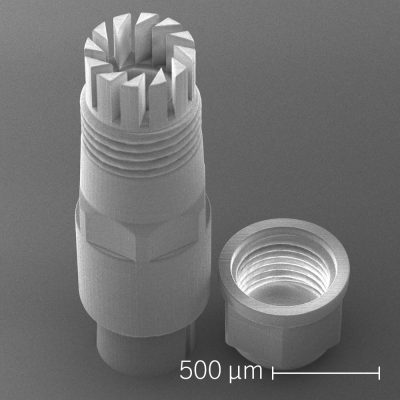

Micro mechanics

UpNano’s printing platforms deliver high-fidelity, movable parts with streamlined production, solid output, and a wide range of resin options backed by comprehensive material data sheets.

- Manufacturing fully functional, movable parts in a single print job

- Fully cured parts right out of the printer

- High-performance resins with a wide range of mechanical properties

- Large range in resolution from single lines of 150 nm in diameter to fully functional devices up to 40 mm³ in size

- Material data sheets and mechanical properties available for every resin in the portfolio

UpNano’s printing platforms excel in manufacturing high-fidelity, movable parts in a single print job. UpNano’s platform streamlines your production process and reduces part assembly time. Solid, highly crosslinked parts are delivered right out of the printer, ensuring durability and reliability in your product with minimal post-processing. Resins range from soft and flexible to strong and rigid, covering a broad range of applications. Comprehensive material data sheets for every resin in our portfolio offer transparency and confidence in your material selection process.

Medical devices

From rapid prototyping to industrial serial production of high-fidelity micro-components for medical devices, including diagnostic tools and treatment devices, as well as microneedle arrays.

- Intuitive fabrication for a variety of geometries

- Fully cured polymer resins for robust part design

- Mold and master production for PDMS casting

- Ability to generate hollow and/or channeled structures

- Several non-cytotoxic resins to choose from

With a push towards custom micro-scale medical devices and equipment, there is an urgent need for additive fabrication techniques that can reliably produce components which cannot be easily fabricated using other methods. The UpNano printing platform provides the optimal tool for medical device and component fabrication. Our high-precision platform ensures rapid generation of high-fidelity parts for a variety of applications. Additionally, UpNano offers multiple non-cytotoxic resin choices as well as resins with a range of stiffness requirements to match the mechanical requirements for a given part.

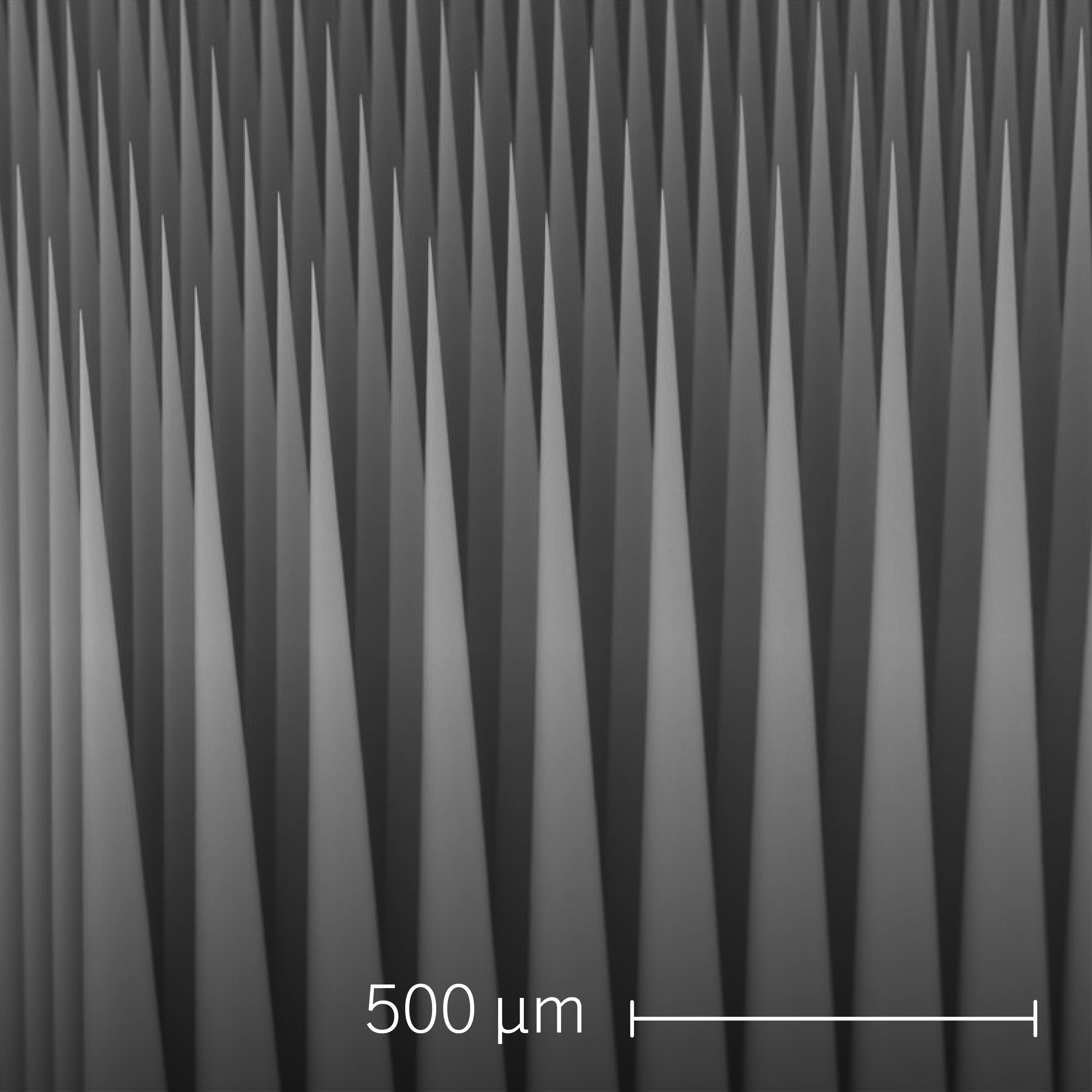

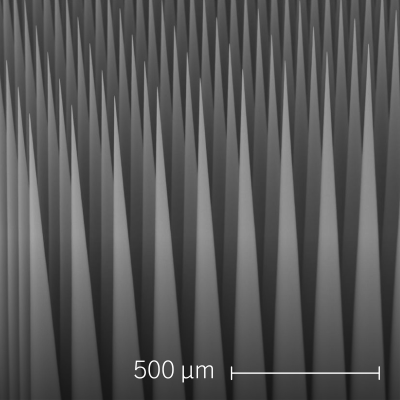

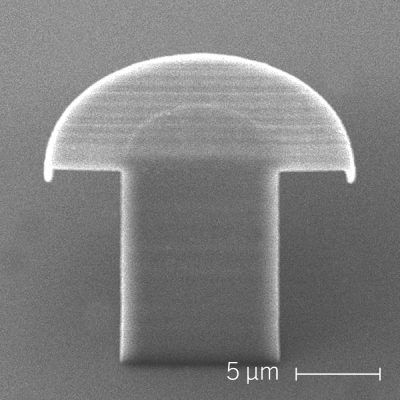

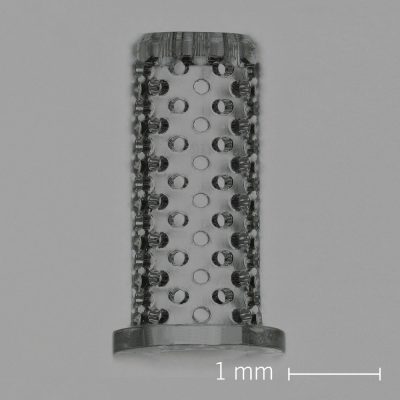

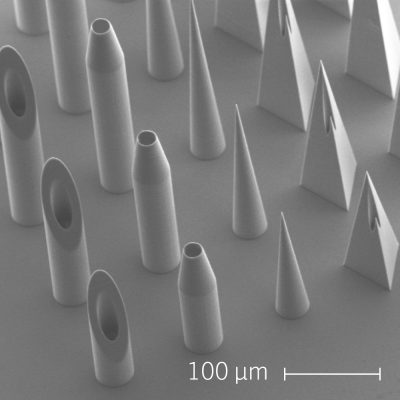

Microneedles

Rapid arrays of high-fidelity microneedles for sampling and drug administration.

Microneedle-based devices offer painless drug or cosmetic delivery and easy blood sampling for at-home diagnostics. However, microneedle designs, ranging from sub-micron to millimeter scale, pose a challenge for mass production. The Think3D user software allows precise microneedle design and fabrication, with adjustable resolution and throughput using our “Adaptive Resolution” function. This ensures rapid creation of microneedles without compromising quality. The platform is ideal for fabricating hollow channel designs for circular or angled channels. Non-cytotoxic resins are available for various applications. Additionally, microneedle molds can be created for high-volume replication processes.

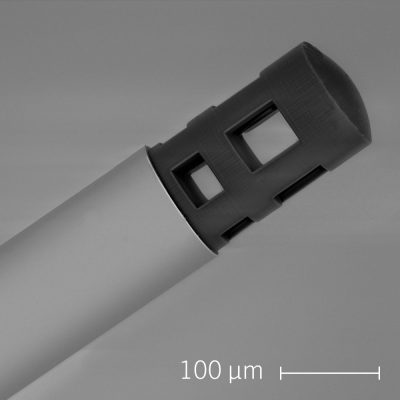

Microfluidics

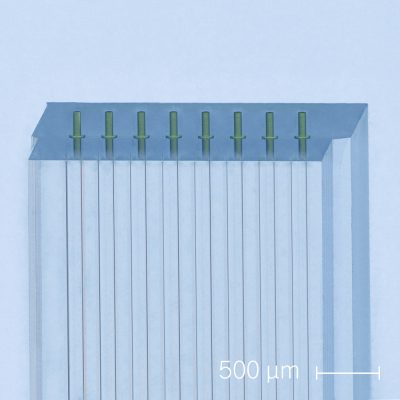

The NanoOne 3D printing platform sets new standards in the production of microfluidic and microphysiological systems.

- Ability to fabricate external-chip fluid interfaces

- In-chip printing of ultrafine elements and scaffolds

- Non-cytotoxic resin with low-viscosity and ultralow-fluorescence

- Finest channel diameter of 10 μm

- Complex internal (3D) geometries

Microfluidics is crucial in the biopharmaceutical industry (for drug screening, diagnostics, LOC, and OOC), yet challenging geometries and internal features hinder broader production with traditional methods. UpNano’s printing platform overcomes these limitations, enabling high-precision manufacturing of in-chip and in-well geometries within commercial chips, as well as entire chip designs with complex internal channel structures as small as 10 µm. Our portfolio of hydrogel and non-cytotoxic resins supports the direct use of manufactured devices. UpFlow stands out from this portfolio with its low viscosity and ultralow fluorescence. Specially designed for microfluidic applications, this resin is ideal for cell-based imaging and fine channels.

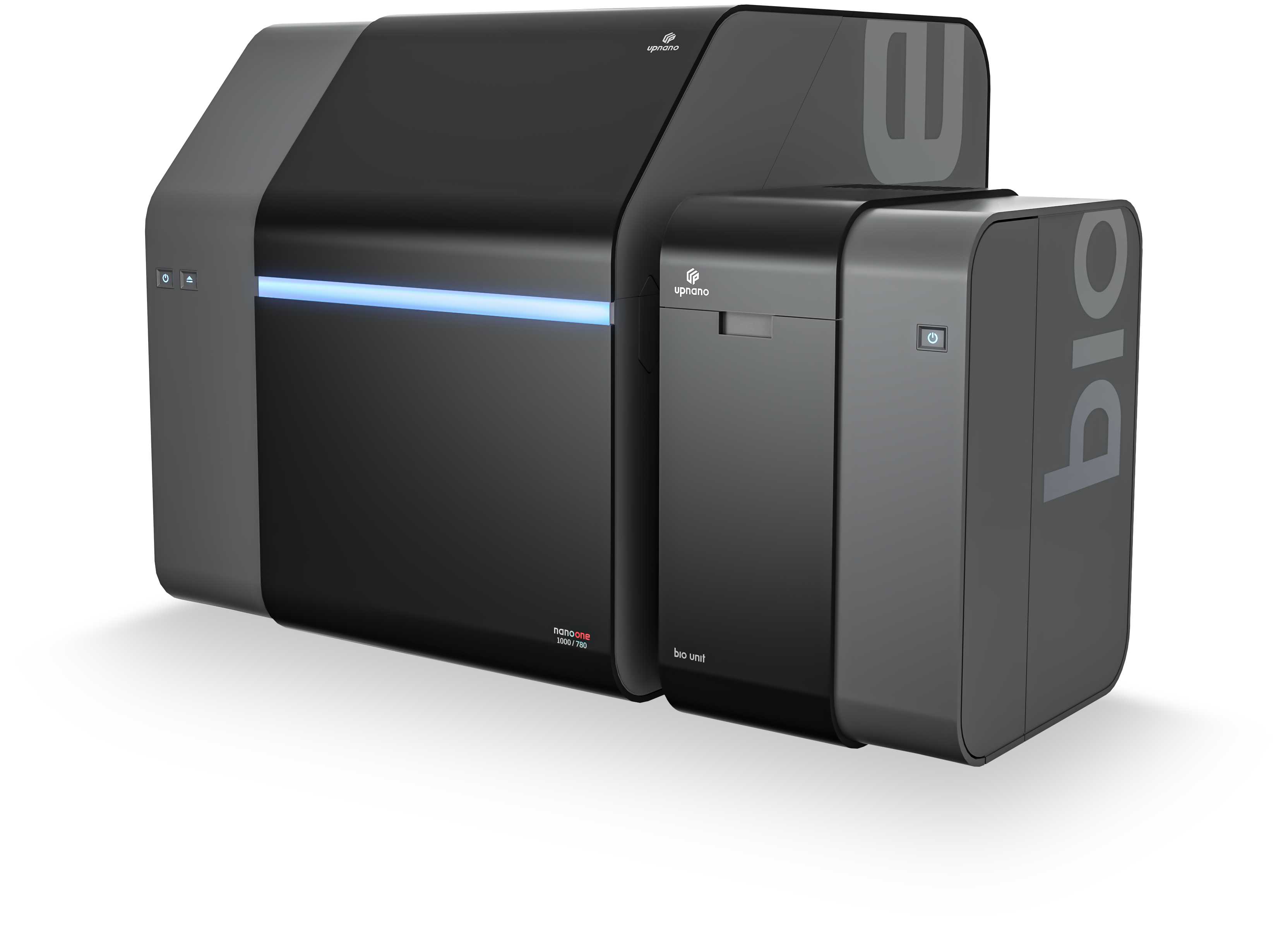

Bioprinting

The only 2PP 3D printing platform with a true incubation system for high-resolution bioprinting applications.

- 3D printing in the presence of living cells or biological materials

- Software widget supporting in-chip and well printing

- ISO7 classified, sterile build room

- Temperature, CO₂, and humidity-controlled print process

- Biocompatible hydrogel and non-cytotoxic resin portfolio

UpNano’s printing platform offers a truly sterile bioprinting experience, with or without the presence of living cells. This is achieved through a HEPA-filtered airstream inside the build chamber and a print setup where the cell culture plate remains closed throughout the printing process. Optionally, the addition of the BioUnit creates a printing environment with controlled temperature, humidity, and CO2 levels. Standard-sized multi-well plates, µ-dishes, commercially and custom-made microfluidic chips, as well as petri dishes, can be used.

A dedicated software feature accompanies the hardware, offering an intuitive and dynamic user interface to create multi-well print jobs. This enables easy print job generation with full parameter control in every well. UpNano has a portfolio of several biocompatible resins certified as non-cytotoxic. Each of these resins has distinct properties, such as low autofluorescence, high elastic modulus, and high temperature resistance.

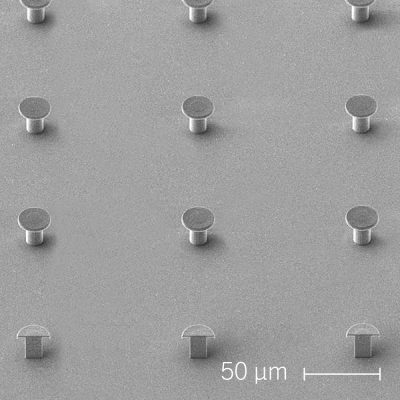

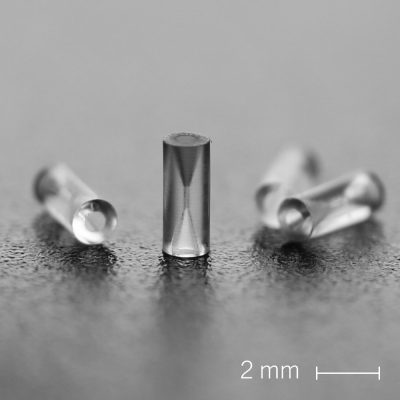

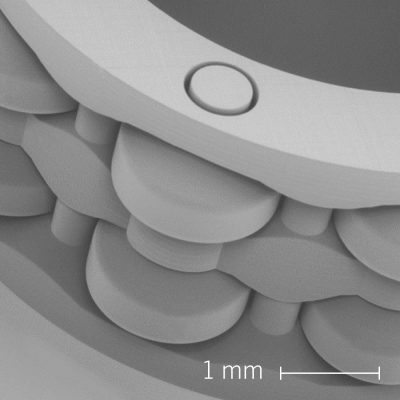

Micro-optics

An innovative tool to craft intricate freeform polymer micro-optics with unparalleled speed and precision, opening a world of unlimited designs.

- Rapid manufacturing of high-precision optical components

- Option for direct printing on wafers, fiber (arrays), and ferrules

- Direct support for lens equations and array functions in data preparation software

- Optical components with surface roughness of less than 10 nm

- Selection of diverse resins offering unique optical properties

Welcome to the forefront of micro-optics manufacturing. UpNano’s innovative printing platform enables you to create high-precision optics with impressive sag heights. From intricate freeform and non-rotationally symmetric lenses to high-fidelity meta lenses, our 3D greyscale lithography offers new possibilities for printing lenses on various substrates like wafers, fiber arrays, and ferrules.

Our Think3D software seamlessly integrates custom lens equations for effortless tessellation into micro lens arrays. Experience unmatched quality with optical components boasting less than 10nm surface roughness. With high shape accuracy and low tolerances, ensure consistency and reliability. Choose from a diverse selection of resins, each offering unique properties such as non-fluorescence, optical transparency, or high refractive index, to tailor your optics perfectly and explore the limitless potential of micro-optics.