NanoPro

Industrial micropart production

Based on high-resolution 2 photon polymerization (2PP) 3D printing technology, our NanoPro service opens new possibilities for the scale up and mass production of industrial microparts at a volume measure and throughput never before seen in the industry.

NanoPro uses a highly efficient and cost-effective process, not achievable elsewhere on the market, to scale 2PP 3D printing technology for the serial production of polymeric microparts. At UpNano, we leverage our specialized manufacturing tools to forge exclusive manufacturing partnerships for our customers, producing their customized parts at scale across a variety of applications.

First fully integrated 2PP-based service model for industrial micropart production powered by our newest 3D printing system – the NanoProVT

You design,

we produce.

Peter Gruber, CTO and Co-founder

“Rapid manufacturing is finally possible for industrial microparts thanks to our 2PP printing platforms: the NanoOne and the NanoPro VT.”

Is NanoPro right for you?

Are you in need of further miniaturization of production parts?

Are your industrial microparts too small or complex for current technology?

Microinjection molding or milling manufacturing options cannot handle your tolerances or design requirements?

Your high-volume need of polymeric microparts cannot be satisfied today?

NanoPro is the solution

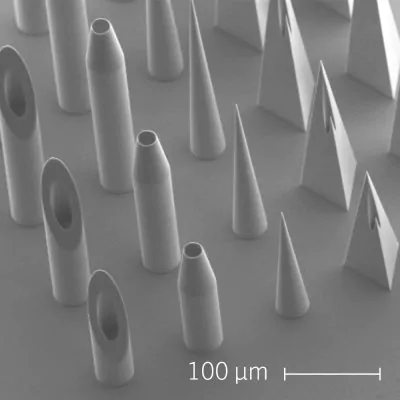

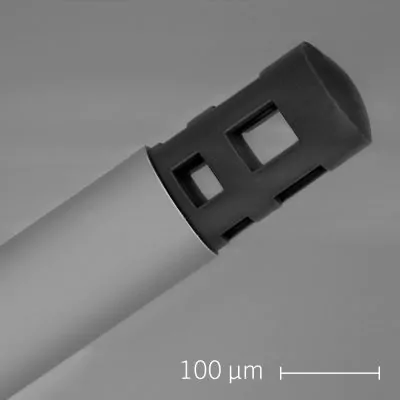

Complex microstructures with unlimited design space

Unmatched tolerances below 100 nm and smallest feature size below 100 nm

Industrial-scale quantities produced by the highest performance 2PP 3D printing technology on the market

Reduce assembly steps, print entire structures in one go

No tooling or post curing required

Planetary gearbox – nine distinct moveable parts printed together with no assembly required

From concept to production: our seamless onboarding and development process

As in many other areas of product development, serial production of microparts with 2PP 3D printing technology needs a stepwise and often iterative process before reproducible and economic production can kick off.

UpNano has structured and defined this process as described below to ensure the launch, commercial supply and growth of a new product can be successfully achieved.

3D prototyping printer

These initial steps should take place utilizing the NanoOne prototyping machine. With a NanoOne machine in-house at the customer’s facilities, the feasibility and early process development steps can be handled in a more hands-on way internally, in collaboration with UpNano’s engineering and design department for support. If needed, these steps can also be done with NanoOne machines on location at UpNano, executed by UpNano experts in collaboration with you.

Step 1: Initialization

- Initial customer contact

- Status or project plan

- Technical specifications

- Economic requirements

- Material requirements

Step 2: Feasibility

- First experimental tests

- General feasibility testing

- Basic adaptation of geometry

- Basic material selection

- First cost estimate (cost per piece)

Step 3: Process development

- Screening of process parameters

- Optimization of print quality

- Optimization of print time

- Optimization of post processing

- Freeze of geometry/material

- Calculation of final cost per piece

- Risk assessment

Step 4: Tech transfer

- Production test runs

- Verification and validation runs

- Yield calculation

Industrial production 3D printer

The later steps of the process transition the development of the micropart(s) to the NanoPro VT print system, owned and managed by UpNano’s experts. After careful validation runs, commercial production can kick off.

Step 4: Tech transfer

- Production test runs

- Verification and validation runs

- Yield calculation

Step 5: Process validation

- Define success criteria

- Verification runs

- Validation runs

- Validation report

Step 6: Production

- Commercial production

- Quality control, packaging, shipment on time, in spec

- KPIs

3D prototyping printer

The initial steps should take place utilizing the NanoOne prototyping machine. With a NanoOne machine in-house at the customer’s facilities, the feasibility and early process development steps can be handled in a more hands-on way internally, in collaboration with UpNano’s engineering and design department for support. If needed, these steps can also be done with NanoOne machines on location at UpNano, executed by UpNano experts in collaboration with you.

Industrial production 3D printer

The later steps of the process transition the development of the micropart(s) to the NanoPro VT print system, owned and managed by UpNano’s experts. After careful validation runs, commercial production can kick off.

3D prototyping printer

These initial steps should take place utilizing the NanoOne prototyping machine. With a NanoOne machine in-house at the customer’s facilities, the feasibility and early process development steps can be handled in a more hands-on way internally, in collaboration with UpNano’s engineering and design department for support. If needed, these steps can also be done with NanoOne machines on location at UpNano, executed by UpNano experts in collaboration with you.

Initialization

- Initial customer contact

- Status or project plan

- Technical specifications

- Economic requirements

- Material requirements

Feasibility

- First experimental tests

- General feasibility testing

- Basic adaptation of geometry

- Basic material selection

- First cost estimate (cost per piece)

Process development

- Screening of process parameters

- Optimization of print quality

- Optimization of print time

- Optimization of post processing

- Freeze of geometry/material

- Calculation of final cost per piece

- Risk assessment

Tech transfer

- Production test runs

- Verification and validation runs

- Yield calculation

Industrial production 3D printer

The later steps of the process transition the development of the micropart(s) to the NanoPro VT print system, owned and managed by UpNano’s experts. After careful validation runs, commercial production can kick off.

Tech transfer

- Production test runs

- Verification and validation runs

- Yield calculation

Process validation

- Define success criteria

- Verification runs

- Validation runs

- Validation report

Production

- Commercial production

- Quality control, packaging, shipment on time, in spec

- KPIs

Respect

Quality

Cooperation

Risk mitigation

NanoPro versus alternative part production options

NanoPro’s 2PP-based 3D printing systems can, at the same time, produce

- A million parts with identical geometries or

- A million parts with individual structural modifications

Precision and tolerance

- Microparts with tolerances below 100 nm and feature sizes below 100 nm

- Complex geometries

- Printing of complex parts with no post-assembly required

Straightforward process

No tooling is required, it is not a replicatory process like MIM or NIL, but a generative, additive technology

High flexibility

Ability to utilize a variety of different substrates and print modii to adapt print processes including part specification and optimized cycle times

Throughput and cycle times

- Throughput and cycle times outperform all other 2PP systems on the market using the fire power of our patented NanoPro VT printing system at 32 Megavoxels/second (million volume pixels/second).

- The NanoPro VT has a throughput of up to several thousand mm3/h, which is factors higher than any other technology.