General Information

Your go-to hub for NanoOne user support

Welcome to HubNano, your comprehensive resource for mastering the world of 3D printing.

Whether you are a seasoned professional or just starting out, HubNano is designed to be your go-to online portal for everything related to UpNano’s 3D printing systems. Dive into our extensive library of quick start guides, detailed operating instructions and expert tips and tricks to get the most out of your microfabrication experience. Explore our in-depth guides for accessories and software explanations to enhance your setup and streamline your workflow.

HubNano is here to support you every step of the way, providing the knowledge you need to optimally operate your printer and innovate.

General information

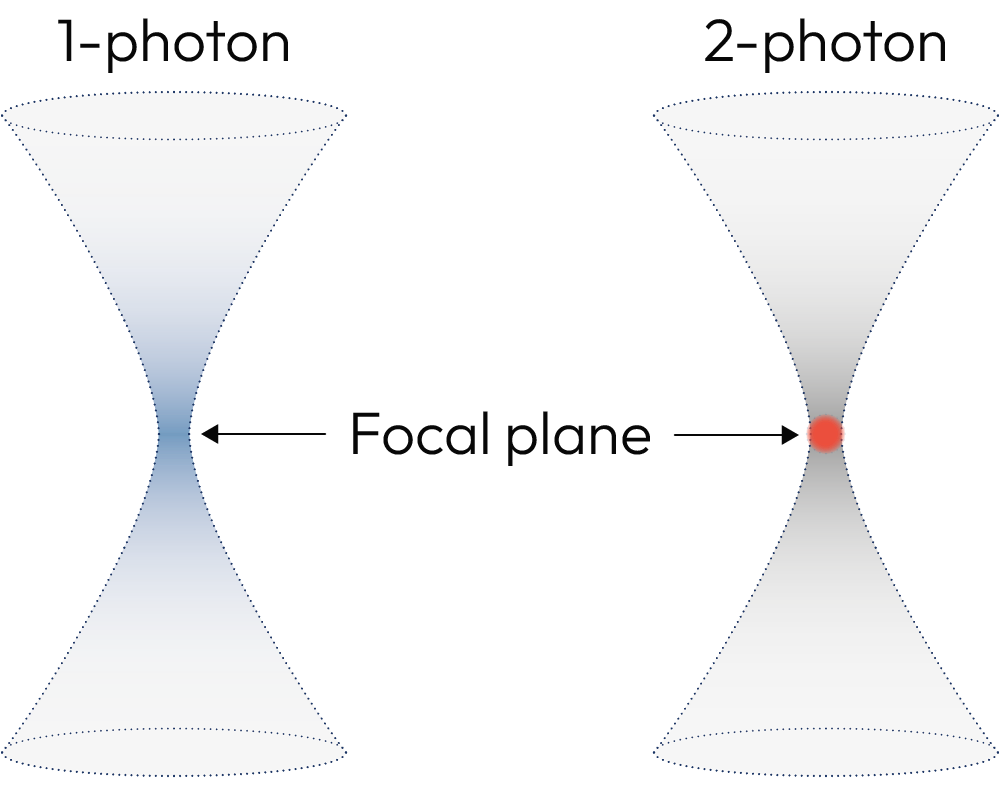

UpNano’s printing systems are based on the technology of 2-photon polymerization which allows for high-resolution 3D printing in the micro- to nanoscale. 2-photon polymerization operates by focusing a high-intensity, femtosecond pulsed laser into UpNano’s 2PP photopolymerizable printing resin, where the two photons are absorbed simultaneously at the focal point, triggering polymerization. Unlike classical SLA processes, which are based on a linear process and polymerization occurs along the entire light path, the non-linearity of the 2PP process leads to printing only at the focal point of the optics. This allows structural details below the 100 nm range.

UpNano thinks holistically and offers platform solutions. The platform excels due to the perfect interplay between the NanoOne printer, the Think3D user software with an intuitive interface, and the proprietary printing resins tailored to various fields of application.

Patented technology, optimized hardware and innovative software make UpNano’s printing systems the most powerful in their class. The NanoOne is a desktop system which fits on a standard lab bench and features high quality key components each playing an important role in overall functionality of the system.

Powerful laser

With up to 1,000 mW of laser power, the NanoOne is the most powerful in its class. The femtosecond fiber laser with 780 nm enables the production of mesoscale structures and the use of special resins that require more energy for curing.

Long-range piezo-stages

All axes (X, Y and Z axis) of the NanoOne are piezo controlled. The sensor resolution of <1 nm, allows the exact positioning of the print substrate over the entire travel distance of 120×100 mm and a height of 49 mm.

HEPA filter

The H14 HEPA filter ensures a clean workspace even if the NanoOne is not operated in a clean room. In the open state, particles are prevented from settling on the components and in the closed / operating state, clean room class ISO 7 standard is maintained.

Vibration isolation

The built-in, high-performance passive vibration isolators make an optical table obsolete. The NanoOne’s can be operated on a stable workbench or chemistry bench – an advantage especially in research and university facilities where space is often at a premium.

Adaptive resolution

The patented Adaptive Resolution process significantly enhances throughput by enabling dynamic switching between two infill modes. In FINE print mode, the laser is precisely focused to achieve maximum resolution using the selected objective magnification, allowing for highly detailed printing. In COARSE mode, the laser focal point can be expanded by up to 10 times, increasing throughput while preserving part properties and maintaining the crosslinking rate. This mode is ideal for fast printing of bulky areas that do not require highest resolution, thus optimizing overall print time.

- High degree of design and manufacturing flexibility

- Compatible with standard substrates up to 40 mm edge length

- Vats equipped with cap for convenient resin storage

- Constant focusing power throughout the printing process

Vat mode

The Vat mode is the standard printing setup of the NanoOne, designed to produce large objects up to 40 mm in height with unmatched precision. The innovative vat design keeps the resin separate from optical components at all times, safeguarding expensive equipment while maintaining constant distance between the objective and the focus plane. The vat is securely positioned on an adapter ring above the objective and the glass substrate is brought into contact with the material. Polymerization occurs layer by layer, with the printed object being gradually pulled out of the vat.

The vat mode also offers significant design and manufacturing freedom, accommodating standard substrates up to 40×40 mm. The unique vat design includes a cap for clean resin storage, and combined with the powerful laser system broad range of materials are supported as well as allowing users to experiment with custom resins.

- High degree of design and manufacturing flexibility

- Compatible with standard substrates up to 40 mm edge length

- Vats equipped with cap for convenient resin storage

- Constant focusing power throughout the printing process

- Compatible with most printing resins from the portfolio

- For structuring directly within glass-bottom substrates

- Enables sterile production of micro-components

Bottom-up mode

Bottom-up print mode is the universal solution for producing high-resolution structures directly within a substrate. This versatile mode is compatible with a variety of resin types and utilizes glass-bottom substrates. Additionally, the Bottom-up print mode supports sterile manufacturing, ensuring a safe working environment for bioprinting.

- Compatible with most printing resins from the portfolio

- For structuring directly within glass-bottom substrates

- Enables sterile production of micro-components

- For the production of complex, freestanding structures

- Printing of structures within a microfluidic channel

- Suitable for sterile manufacturing of structures and bioprinting

- Micro-component manufacturing directly on wafers

Top-down mode

Top-down printing mode is a variation of the bottom-up printing approach, designed to address the unique needs of complex, freestanding structures. This mode is ideal for structuring within the channels of microfluidic chips. It supports sterile production environments, making it suitable for cell-based work. Additionally, this mode accommodates fully-populated prints on wafers of 2 in, 3 in and up to 4 in diameter allowing for a wide range of applications in various industries.

- For the production of complex, freestanding structures

- Printing of structures within a microfluidic channel

- Suitable for sterile manufacturing of structures and bioprinting

- Micro-component manufacturing directly on wafers

Versatility

The NanoOne printing system offers a wide range of flexibility and versatility. With the standard objectives the production of micro parts can be covered along various fields of applications.

The NanoOne printing system stands out for its exceptional versatility, offering a broad range of substrate options to meet various application needs. Users can print on UpNano’s standard glass substrates, which are available in sizes ranging from 10×10 mm, 20×20 mm, and 1 in round, to 40×40 mm. For larger-scale projects, the system supports 2 in, 3 in and up to 4 in pre-coated wafers and can also print on up to 2 in wafers using UpNano’s standard liquid resins. The NanoOne system is also capable of handling more delicate tasks, such as printing on single fibers or fiber arrays with up to 16 fibers. Additionally, it supports biological substrates, including petri dishes, slide wells, and well plates, accommodating up to 96 well plates. To ensure the highest precision, all these substrates can be tilt-corrected, ensuring optimal accuracy for even the most intricate prints.

Printing Resins

UpNano not only develops high-resolution 3D printing systems, but the holistic approach is also reflected in the product portfolio of 2-photon resins. The goal is to provide matching resins for every application optimized to utilize the full potential of the ultrafast NanoOne system. The resin portfolio includes nine resins each with special properties for specific applications – from performance printing resins to optically-transparent resins for optical and microfluidic applications to biocompatible formulations tested for in-vitro cytotoxicity according to EN ISO 10993-5:2009.

The resins are optimized to realize 2PP rapid prototyping and batch production, reducing the time needed for iteration cycles to a minimum. With the in-house developed resins, a throughput is achieved that remains unmatched in the industry.

Since the NanoOne is an open platform, in addition to the UpNano photo resins and partner materials from BioInx or Glassomer, commercially available third-party materials or custom resins can be used as well.

Additionally, to meet customer specific requirements, UpNano also offers material adaptations and proprietary material developments to be able to realize the desired property profiles of specific applications.

|

|

40x

|

20x

|

10x

|

5x

|

10x

|

||

|---|---|---|---|---|---|---|---|

|

Platform

|

nanoOne 250

|

|

|

||||

|

NanoOne 1000

|

|

||||||

|

NanoOne bio

|

|||||||

|

Numerical aperture

|

1.4

|

0.7

|

0.4

|

0.25

|

0.3

|

||

|

Working distance

|

0.13 mm

|

0.35 mm

|

3.1 mm

|

12.5 mm

|

10.0 mm

|

||

|

Immersion media

|

Oil

|

Water

|

Air

|

Air

|

Air

|

||

|

Horizontal feature size

|

≤220 nm

|

≤420 nm

|

≤730 nm

|

≤1.2 μm

|

≤980 nm

|

||

|

Vertical feature size

|

≤550 nm

|

≤2.9 μm

|

≤9.2 μm

|

≤23 μm

|

≤16.4 μm

|

||

|

Field of view

|

Ø 0.5 mm

|

Ø 1 mm

|

Ø 2 mm

|

Ø 4 mm

|

Ø 2 mm

|

||

|

Typical writing speed

|

150 mm/s

|

300 mm/s

|

600 mm/s

|

1,200 mm/s

|

600 mm/s

|

||

|

Throughput fine mode

|

0.05 mm³/h

|

0.25 mm³/h

|

4 mm³/h

|

30 mm³/h

|

6 mm³/h

|

||

|

Throughput adaptive resolution

|

0.25 mm³/h

|

2.25 mm³/h

|

40 mm³/h

|

300 mm³/h*

|

60 mm³/h

|

||

* By adapting the parameters, a throughput of >450 mm³ per hour can be achieved.

Think3D™ user software

The Think3D™ data-preparation software supports the user in a unique, intuitive way. Structures can be imported directly into the software as STL files or geometries can be built up from predefined structural elements. The Think3D software supports the user throughout the entire printing process in an instinctive and easy way.

- Print job files including all parameter settings

- Reproducible production of identical or different objects

- 3D preview of the created print job

- Real time processing of data

- Adaptive resolution for highest resolution where needed

- Remote monitoring, integrated and automated

- Advanced logging feature including user accounts

- Visualization of field of views and easily tailored

- Customized part design with STLs or G-Code

Intuitive interface

The user interface design is intuitive and easy to use. The graphical 3D preview provides an overview of the job design, the field of view as well as stitching and slicing position.

Printing profiles

Predefined print profiles, which are optimized for the selected objective and resin, guarantee simplicity of use and fast print results in excellent quality.

Sub-jobs

By using the sub-jobs function, individual printing parameters can be applied for single parts or groups. Therefore, high-resolution and high-speed regions can be combined into one print job.

Well-plate mode

With the well-plate wizard, it is easy to assign a different structure to each well and/or to vary the parameters from one well to another in a standard cell cultured plate.

Downloads

Please click image to download the document.