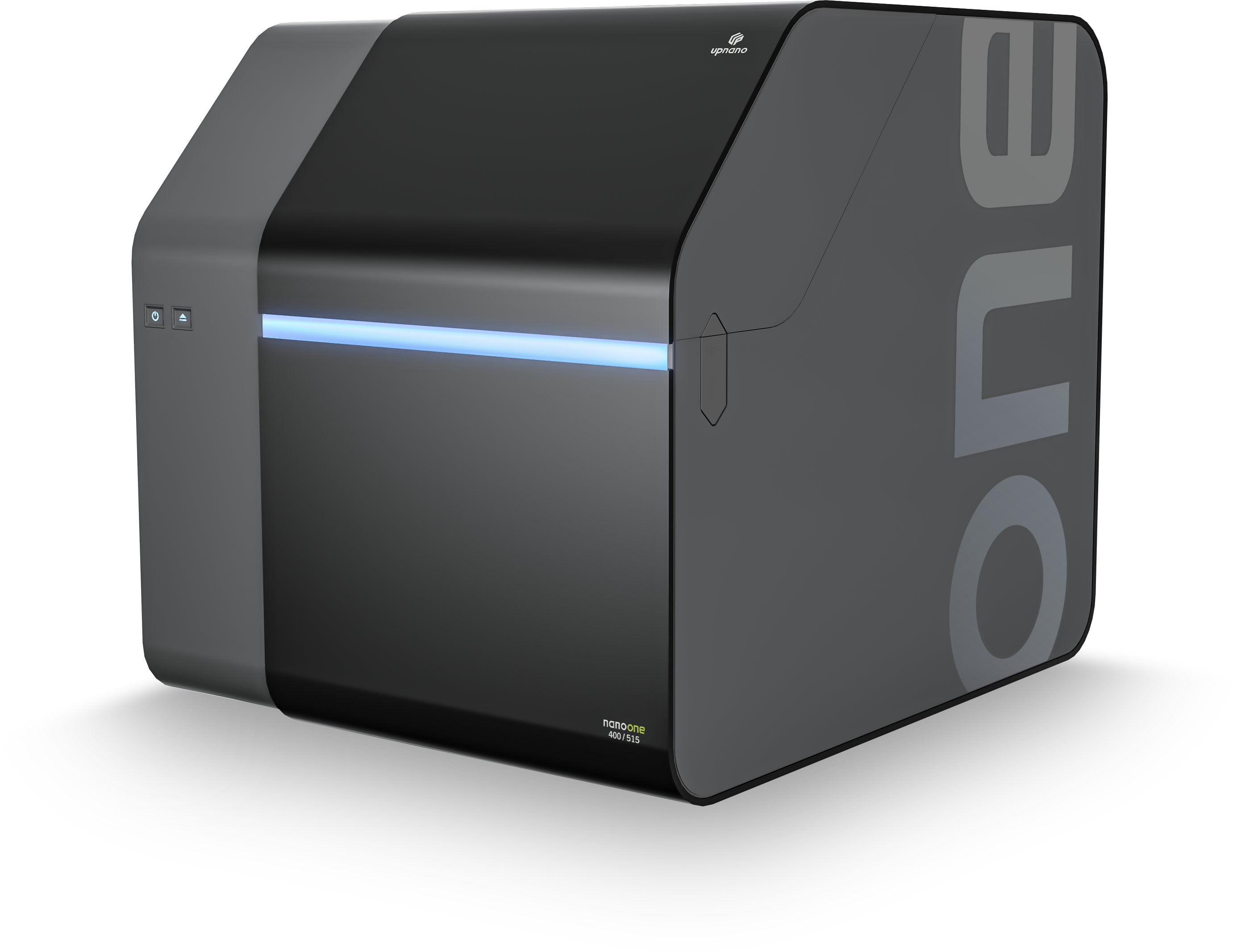

3D printers

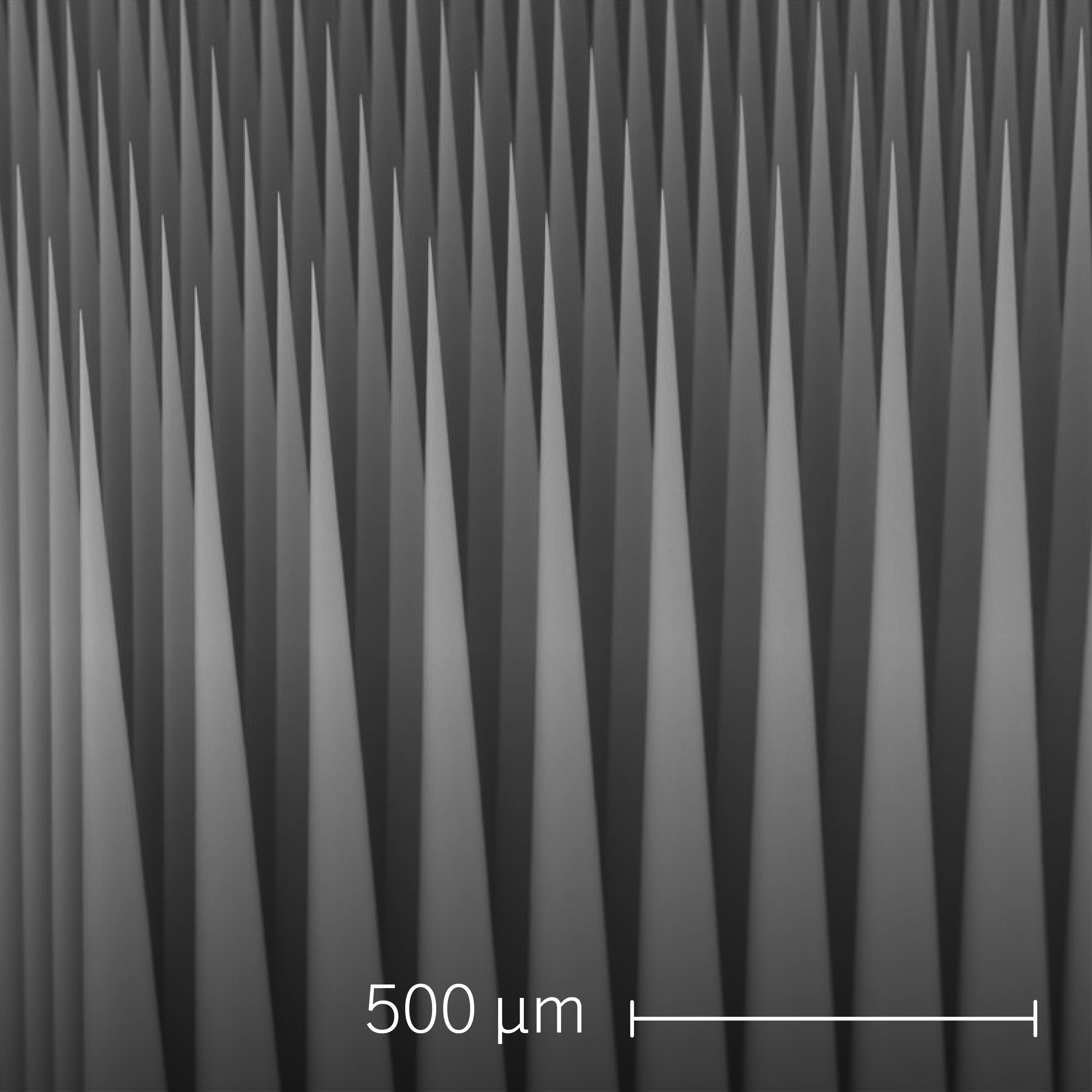

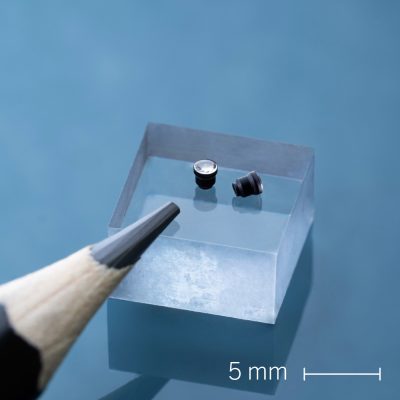

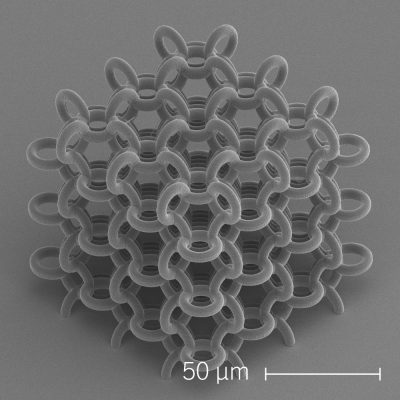

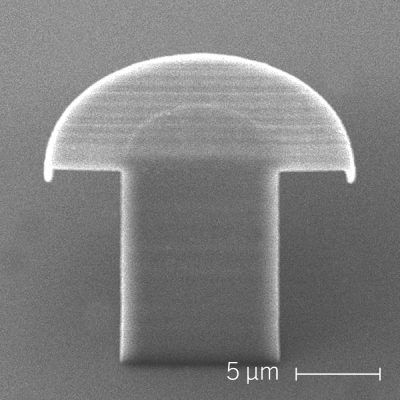

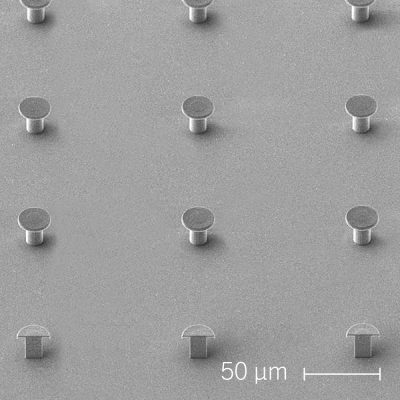

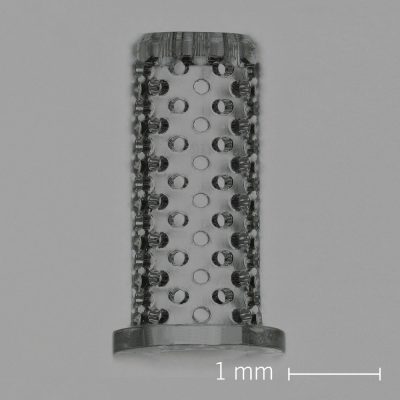

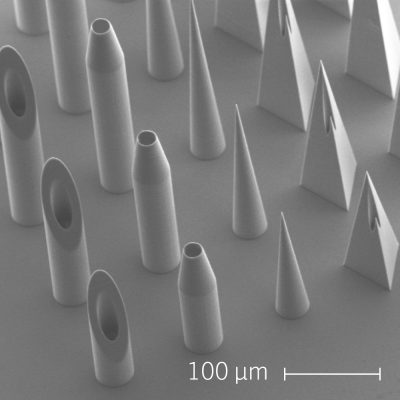

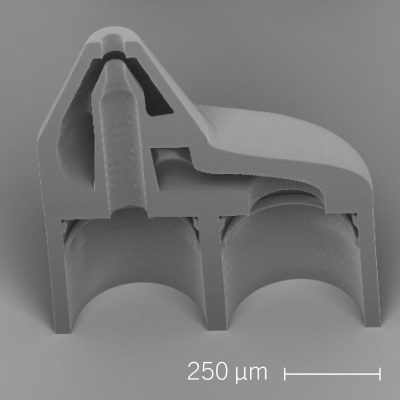

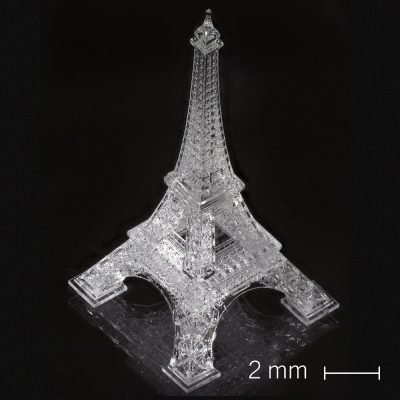

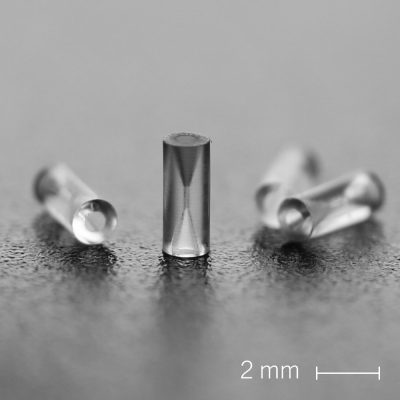

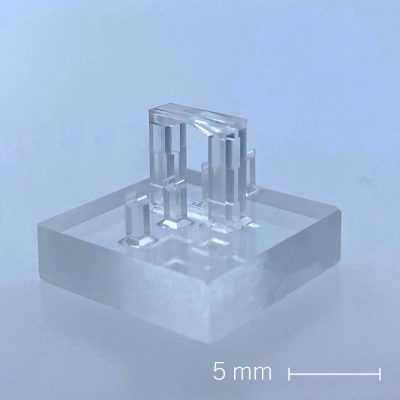

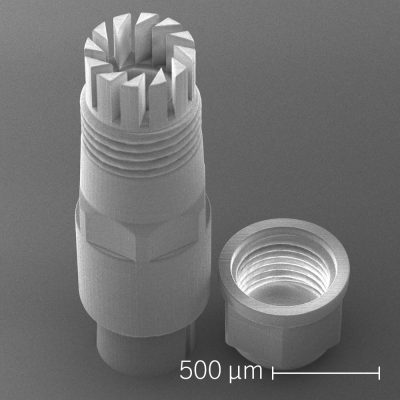

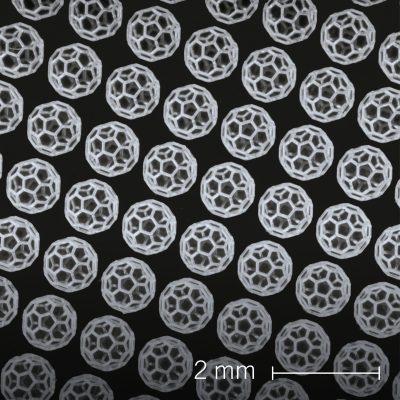

Introducing a revolutionary desktop printer series merging additive manufacturing flexibility with industrial production demands. Based on multiphoton lithography, this versatile technology allows for the manufacturing of highest precision components with structural details below 100 nm and macroscopic microparts in the centimeter range, empowering users to create nano- and microstructured parts across various sectors. Dive into the future of micro-manufacturing with UpNano’s user-friendly, fast process.

New

Now available with a laser wavelength of 515 nm or 780 nm

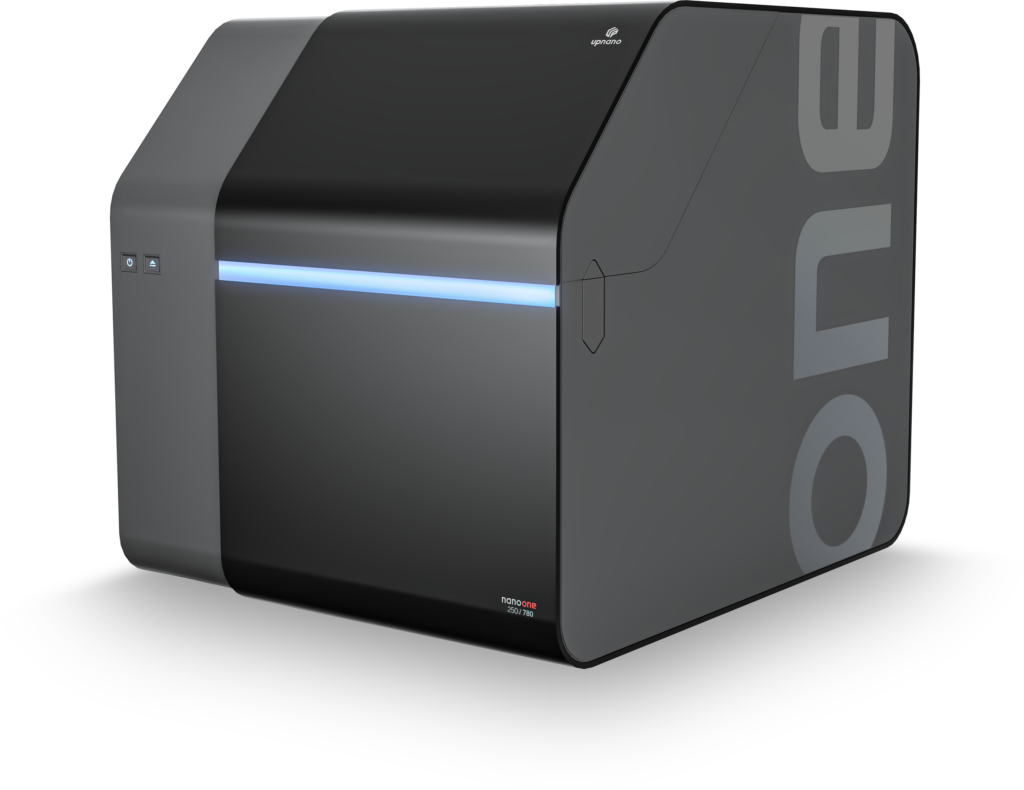

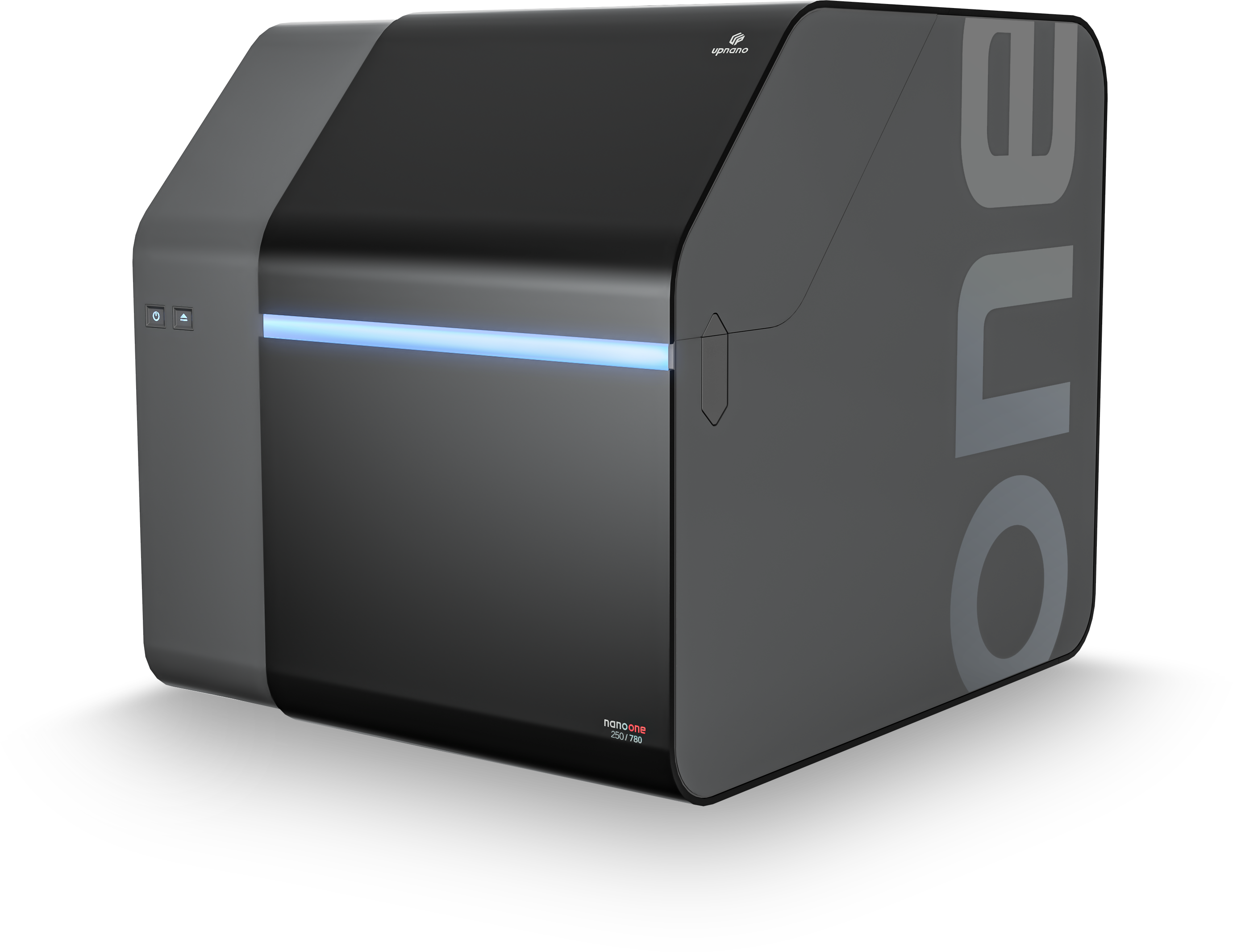

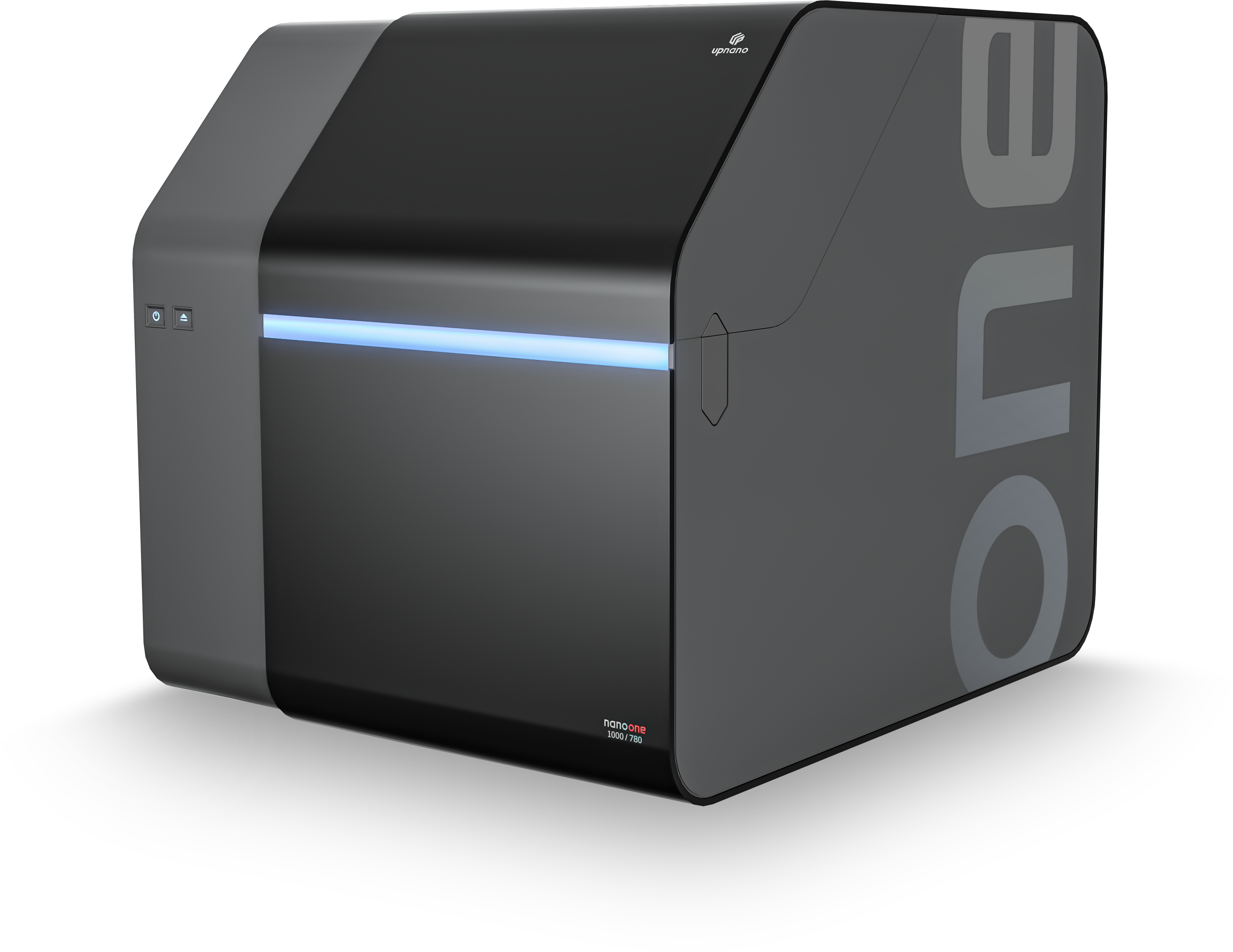

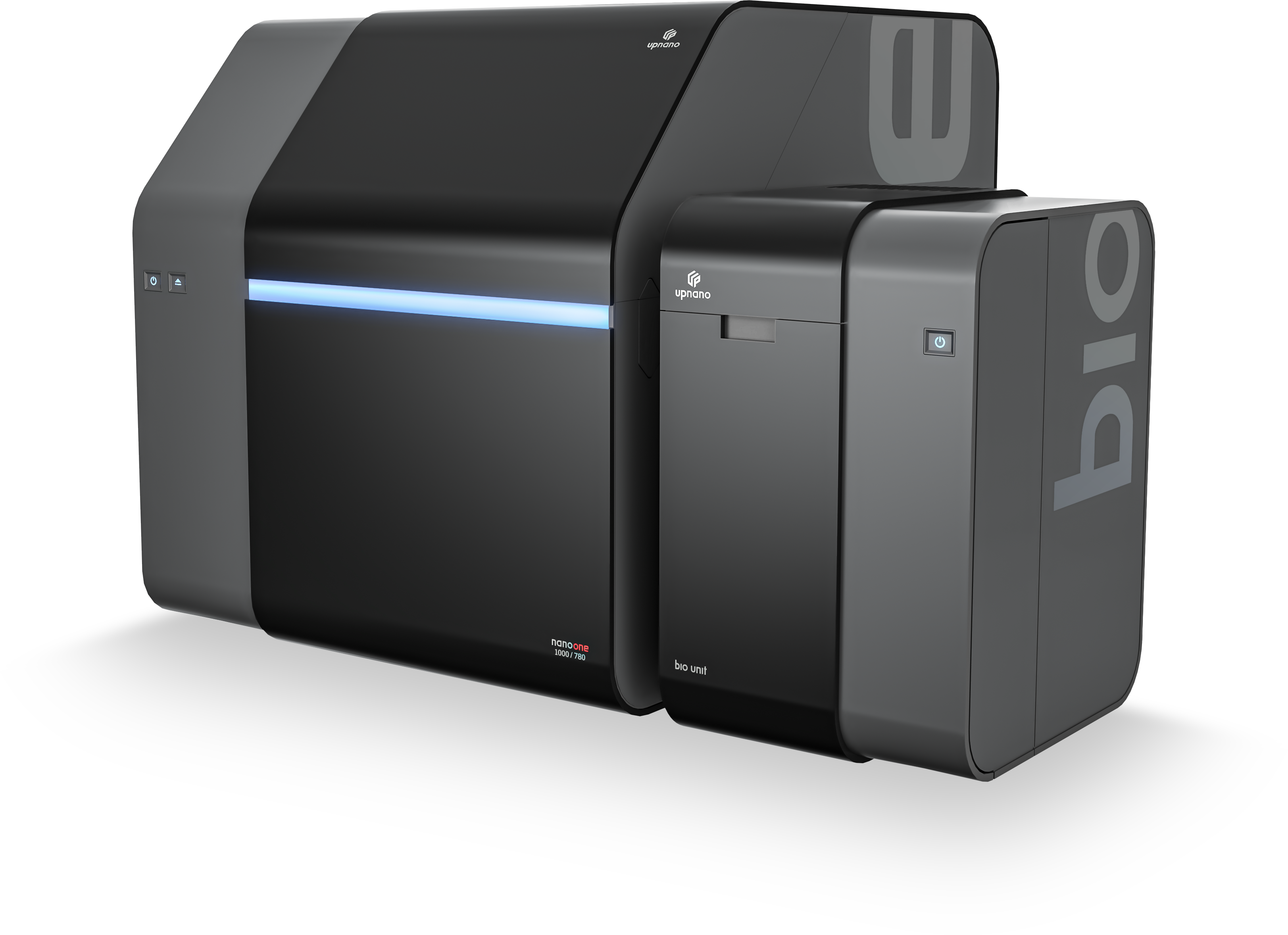

NanoOne models

*Power in the sample depends on the selected objective and is lower than the output power of the laser. For further information, ask the UpNano sales team.

Step into the future of 3D printing

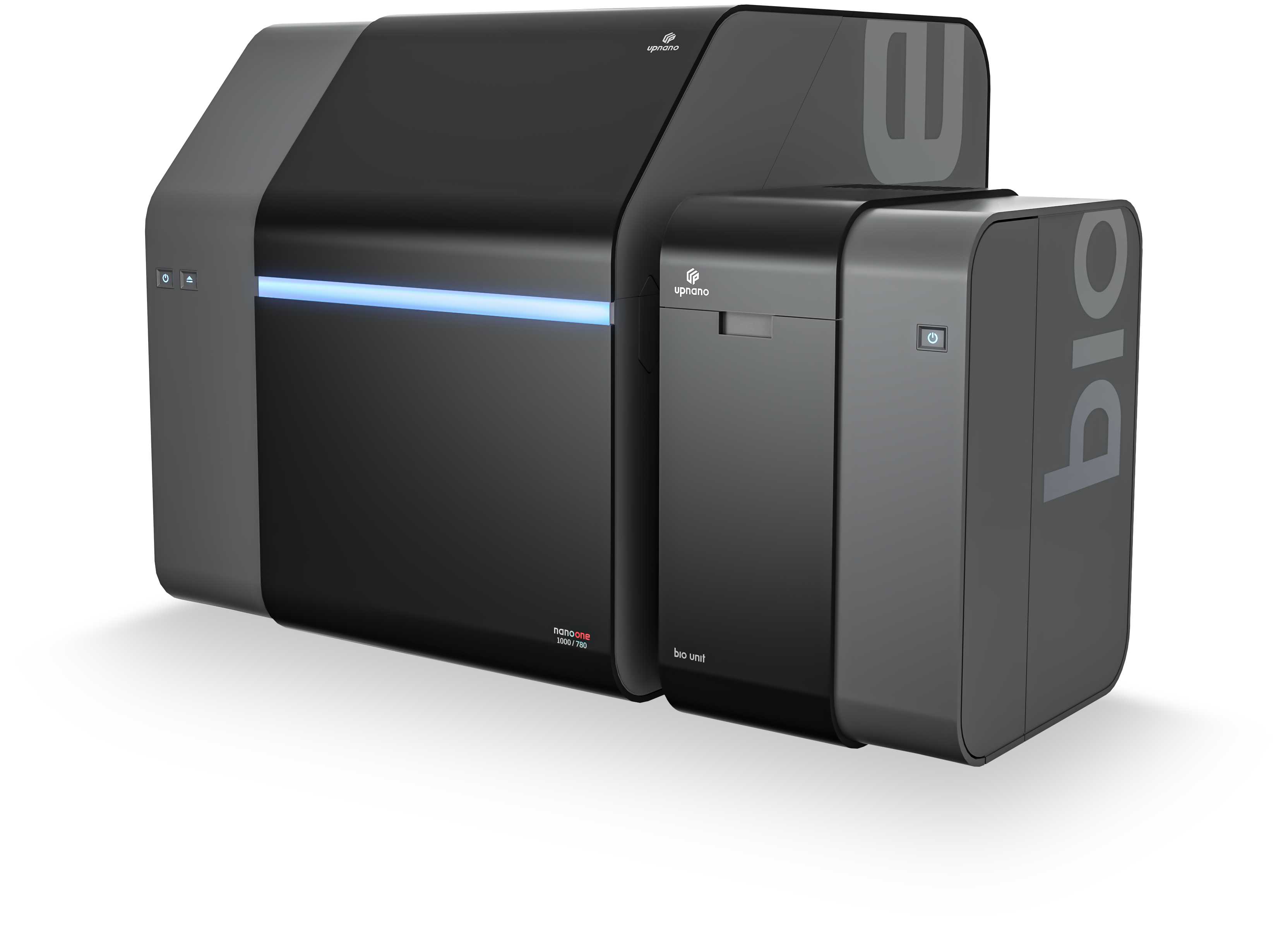

NanoOne empowers users across various sectors to create high-resolution microstructured parts tailored to their specific needs, right from the very first batch. This system opens doors in fields ranging from electronics to micro-optics and even biocompatible applications in cell and medical research. Say hello to the future of micro-manufacturing with NanoOne.

Compact and modular

benchtop system

Most powerful laser in its class available in 780 nm or 515 nm wavelength

Integrated

optical table

Built-in HEPA

filter system

Long-range

piezo stage

Real-time

slicing engine

Proprietary

adaptive resolution

Dip-in-free

printing process

Powerful, easy to use

software

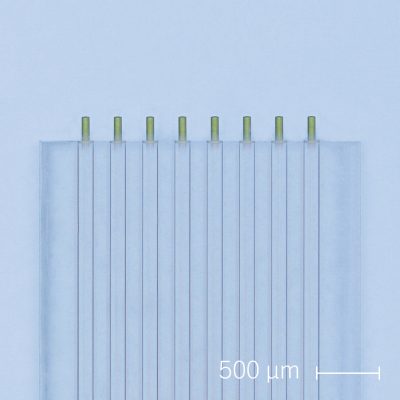

In-chip and

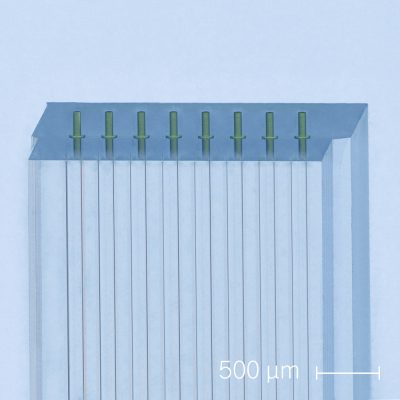

in-well printing

Outline mode for

surface finish

Unmatched

throughput

Certified quality

Denise Hirner, COO and Co-founder

“In order to meet the industry’s quality and environmental standards, our company holds ISO 9001 and ISO 14001 certification. Quality is our daily commitment. It’s how we consistently provide reliable tools for production that’s built to last.”

Unmatched speed from our Adaptive Resolution technology

➔

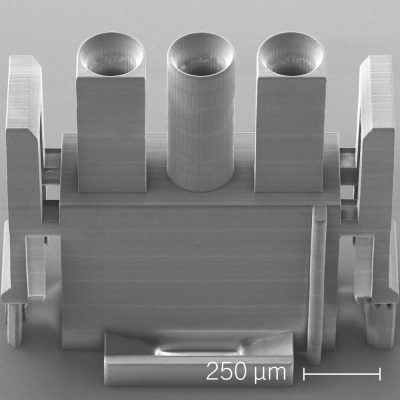

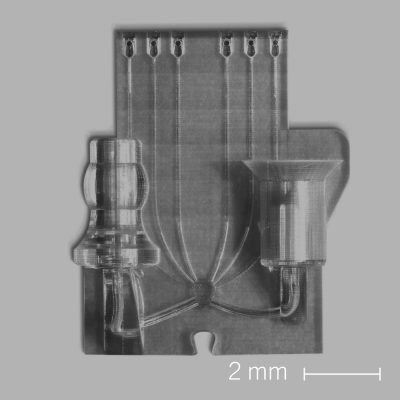

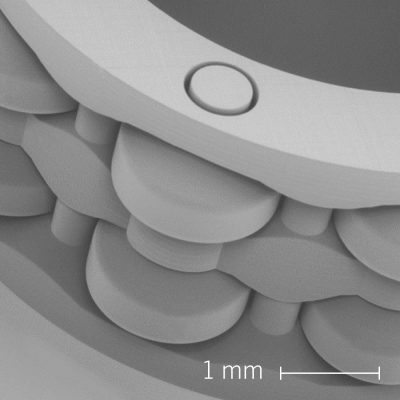

The patented UpNano Adaptive Resolution technology significantly enhances throughput by dynamically modifying the voxel size. The laser focal point can be optimized for different printing segments: broadened for bulk areas and finely tuned for outer shells and intricate details. This way, customers can manually customize resolution levels for specific areas and segment components based on their needs. Additionally, the Adaptive Resolution infill mode in the THINK3D software can automatically distinguish between high and low-resolution areas within a selected geometry, automatically adjusting the laser voxel size as needed.

Clean even without a clean room

➔

In the production of micro and nanoscale components, maintaining a clean working environment with minimal particle levels is crucial. That’s why NanoOne printing systems come equipped with an H14 HEPA filter by default. With the NanoOne, you can maintain clean room class ISO7 standards loading and unloading. During the printing process, the filter system ensures that no particles larger than 0.3 micrometers are detectable. This means achieving low-contamination loading and unloading, and contamination-free printing, all without the need for a dedicated clean room.

Compensation of substrate tilt

➔

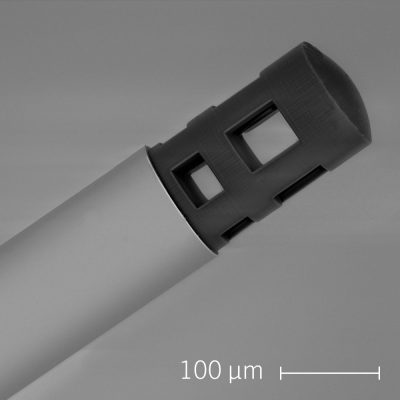

The integrated NanoOne autofocus function accurately determines the tilt of the substrate and compensates for it using precision actuators, ensuring the highest platform planarity. Substrate tilt compensation enables the reproducible production of large and/or thin structures with the NanoOne printing system. The substrate tilt compensation insert is compatible with all standard substrates and can also be combined with special holder systems for printing on glass fibers, ferrules, and wafers. Achieve unparalleled planarity and versatility for various printing needs with NanoOne.

Unlock unparalleled precision and performance with NanoOne:

Achieve minimal horizontal feature sizes down to <100 nm

Create vertical features down to <190 nm

Attain surface roughness levels ≤10 nm

Experience unmatched throughput >450 mm³/h

Benefit from industry-ready writing speed ≥1000 mm/s

Utilize an accessible writing area 100x120 mm

Print structures up to an incredible height of >40 mm

Enable sterile in-chip and -well printing with living cells

Trust in NanoOne’s industry-proven tolerance and yield

Achieve minimal horizontal feature sizes ≥170 nm

Create vertical features down to ≥550 nm

Attain surface roughness levels ≤10 nm

Experience unmatched throughput >450 mm³/h

Benefit from industry-ready writing speed ≥1000 mm/s

Utilize an accessible writing area 100x120 mm

Print structures up to an incredible height of 40 mm

Enable sterile in-chip and -well printing with living cells

Trust in NanoOne’s industry-proven reproducibility and yield

Innovative manufacturing solutions Made in Austria

Having originated in Austria, our company has evolved into a globally recognized provider of high-resolution 3D printing technology, reaffirming our commitment to quality and domestic partnerships. Ensuring quality, reliability, and sustainable production is our top priority, guiding our choices of manufacturing partners and suppliers. All UpNano printing systems are assembled, tested, and shipped directly to our customers worldwide from our headquarters in Vienna.

Multiphoton lithography systems are high-tech equipment designed and manufactured for industrial production, consisting of hundreds of high-performance components. Therefore, in evaluating our suppliers, we prioritize close collaboration and communication to deliver the highest quality “Made in Austria” to our customers.

The heart of our 3D printing platform NanoOne, the femtosecond laser, comes straight from the melting pot of innovation: Silicon Valley

The most compact, powerful, and air-cooled laser enables innovative manufacturing processes and connects us to one of the most innovation-driven countries in the world, the United States of America. It serves as our second home and the location of our branch office in Boston, MA.

Implementing ISO 9001 means our company must put effective processes in place and train our staff to deliver flawless products and services to our customers time after time.

Benefits of ISO 9001 quality management include:

Process

improvement

Customer

confidence

Effective complaint resolution

Ongoing

optimization

Process

improvement

Customer

confidence

Effective complaint resolution

Ongoing

optimization

ISO 14001 provides a framework for UpNano to continually improve our environmental performance. In an age of heightened environmental consciousness and increasing global challenges, it is important for us to address these pressing concerns.