2-photon polymerization

UpNano specializes in providing system solutions for additive manufacturing (AM)

According to the ISO-definition, additive manufacturing is a process of joining materials to make parts from 3D model data, usually layer upon layer, in contrast to subtractive manufacturing and formative manufacturing techniques. The term “additive manufacturing” encompasses various 3D printing technologies, notably stereolithography (SLA) and 2-photon lithography (2PL), known for their remarkable resolution achieved through light-based methodologies. This capability enables the production of objects with intricate details and fine features, as light can be precisely focused on a small focal point.

Stereolithography and 2-photon lithography

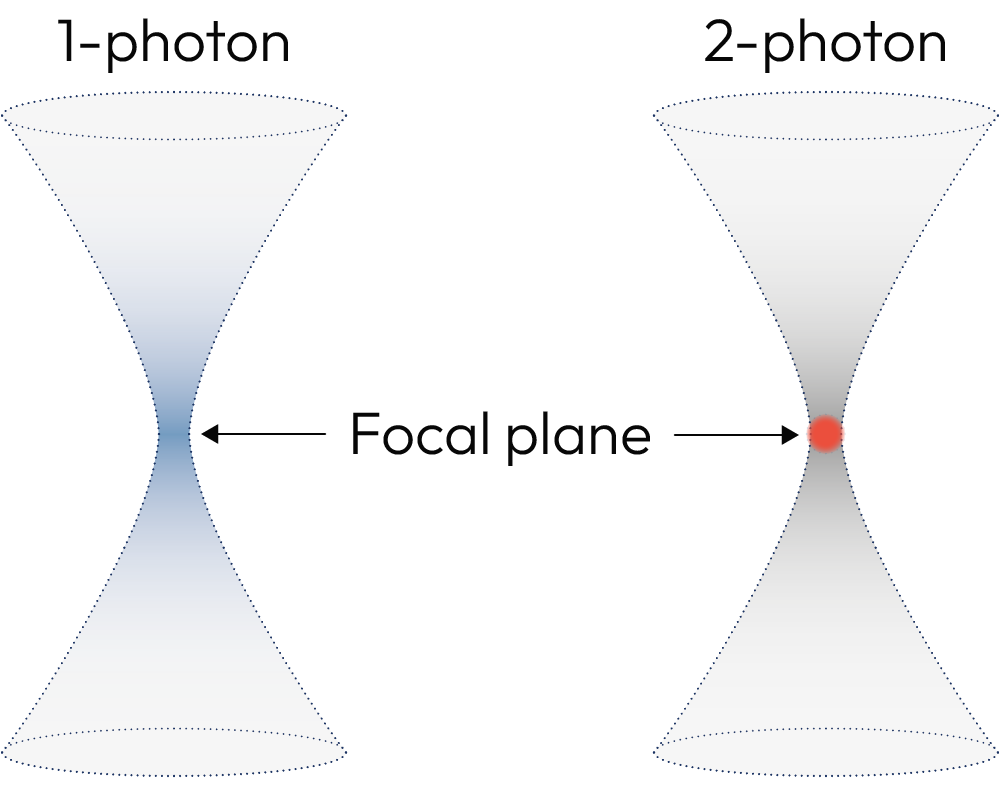

Both SLA and 2PL operate on a shared principle: the utilization of light absorption to initiate photopolymerization. Despite achieving similar outcomes in altering material properties, their mechanisms of light absorption differ. In SLA, light absorption occurs linearly along the beam path, whereas in 2PL, absorption is localized and limited to a small volume around the focal point. The difference lies in SLA’s linear absorption and 2PL’s non-linear, 2-photon absorption (2PA) mechanism.

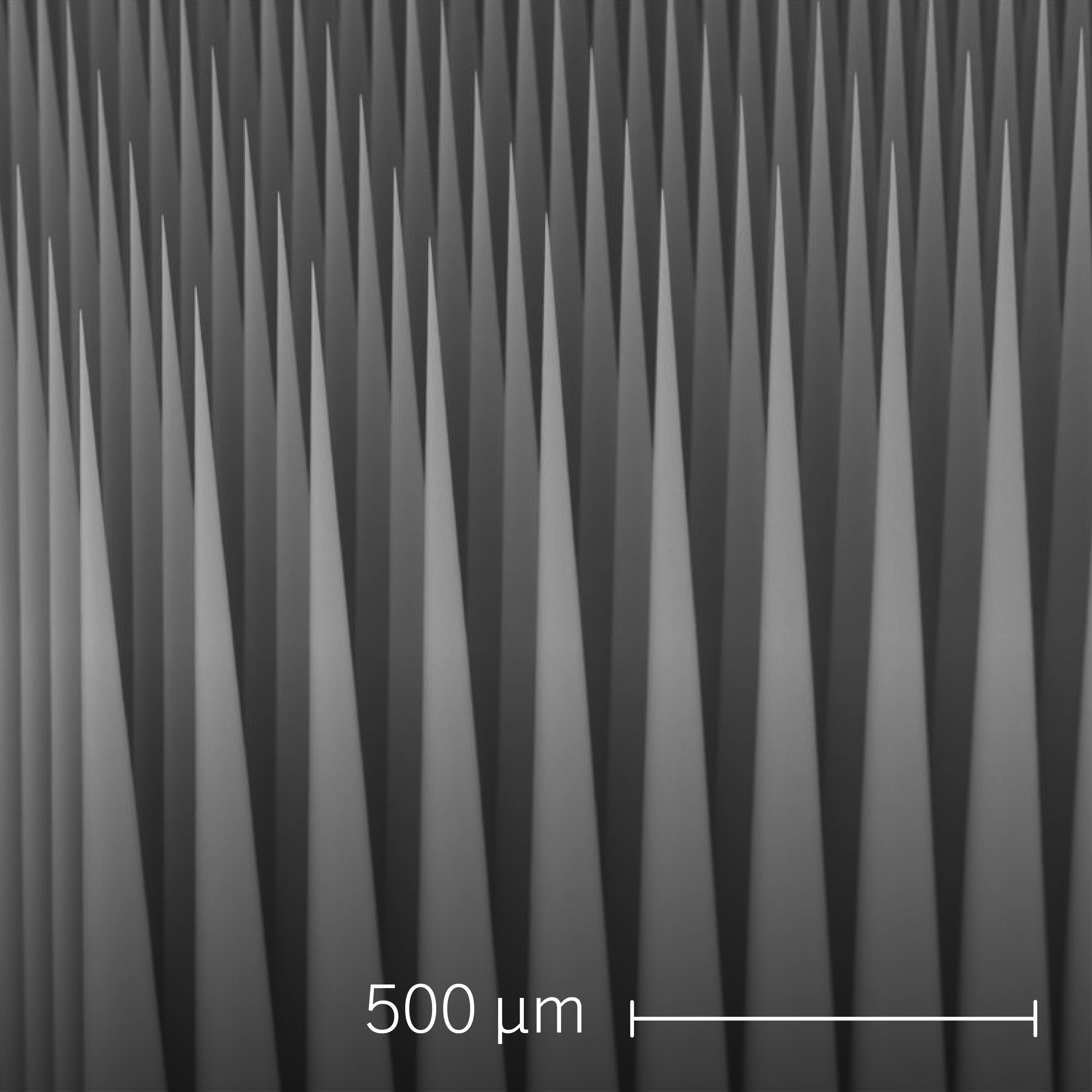

A direct comparison between the single (linear) and multi-photon (non-linear) beam paths in fluorescence microscopy reveals that 2PA only occurs at the focal point of the beam. Consequently, monomer crosslinking is only induced at the focal plane, as polymerization is dependent on this non-linear absorption – whereas in the case of 1-photon absorption, the emitted light is absorbed along the entire beam. This fundamental difference explains why parts produced with one-photon based processes, like stereolithography, are created layer by layer, while two-photon polymerization (2PP) parts can be printed in a pre-defined volume of resin with a resolution finer than 1 µm.

2-photon and multiphoton polymerization as emerging manufacturing standards for micro-components

UpNano’s advanced high-resolution 3D printing processes are based on 2-photon polymerization (2PP), which enables unparalleled highest resolution within the sub-micrometer range. This is achieved by leveraging the spatial selectivity of 2-photon absorption (2PA), where the probability of 2PA significantly reduces beyond the focus point, leading to a decrease in the fluorescent volume and resulting in the highest spatial resolution.

This unique attribute of the 2PP process allows printing directly within the resin volume, eliminating the need for repetitive material coating as in SLA processes. This is particularly significant as it eliminates any pulling processes or associated stresses on fine structural details during printing.

The versatility of the process allows for various approaches to produce structures or parts. It can be additive, as in 2PP, subtractive through photodegradation, or modificative via photografting. While UpNano’s printing platforms support all these approaches, their primary application lies in the additive production of 3D micro-components. 2PP 3D printing is also the method of choice if microinjection molding comes to its boundaries with respect to complexity of geometries, part smallness or frequent design modifications.

While outcomes may differ depending on the chosen process approach, the fundamental principle remains dependent on 2-photon excitation of a photosensitive compound and subsequent 2PA.